A system and method for real-time measurement of the temperature inside the formwork during directional solidification

A technology of directional solidification and real-time measurement, which is applied to thermometers, thermometers using directly heat-sensitive electrical/magnetic components, measuring devices, etc. problems such as the temperature measurement requirements of the inner alloy liquid to achieve the effect of low cost and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

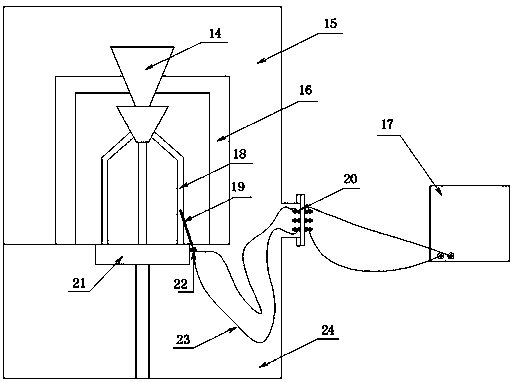

[0022] The present invention will be further described below in conjunction with the drawings.

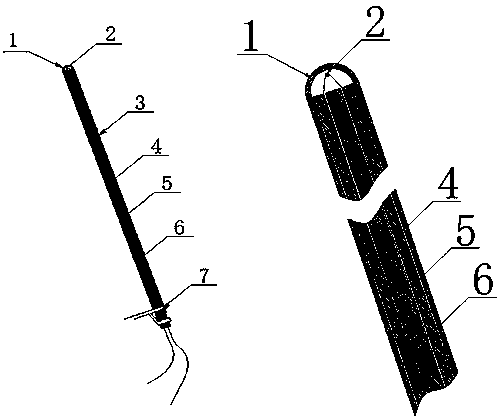

[0023] The technical scheme adopted by the invention includes a thermocouple, a fixing device, a connecting plate, a wire, and a data recording device.

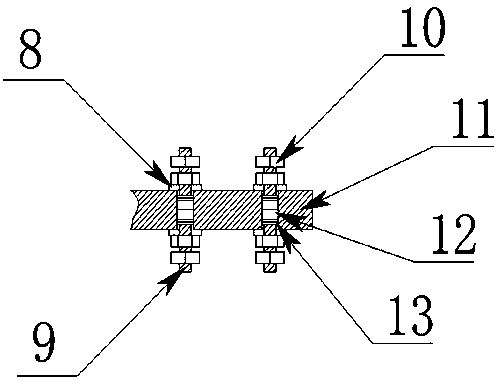

[0024] Thermocouples include single-hole thick ceramic tube 3, double-hole fine ceramic tube 4 and type B thermocouple wire, thick ceramic tube welding dead end 1, thermocouple wire positive and negative welding point 2; fixing device 7 is fixed in the directional solidification furnace On the water-cooled copper plate, there are two upper and lower clamps for fixing the thick and thin ceramic tubes; the first connecting plate 22 is fixed on the drawing device of the directional solidification furnace, and the second connecting plate 20 is fixed at the temperature measuring hole of the directional solidification furnace. The disc includes a sealing sleeve 8, a copper column 9, a fastening nut 10, a stainless steel flange 11, a sealing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com