Fiber coupling connector

A fiber optic coupling and connector technology, which is applied in the field of fiber optic coupling connectors, can solve problems such as poor molding, plug mechanism components and socket mechanism components cannot be docked, and achieve the effect of not easy tightness and smooth docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

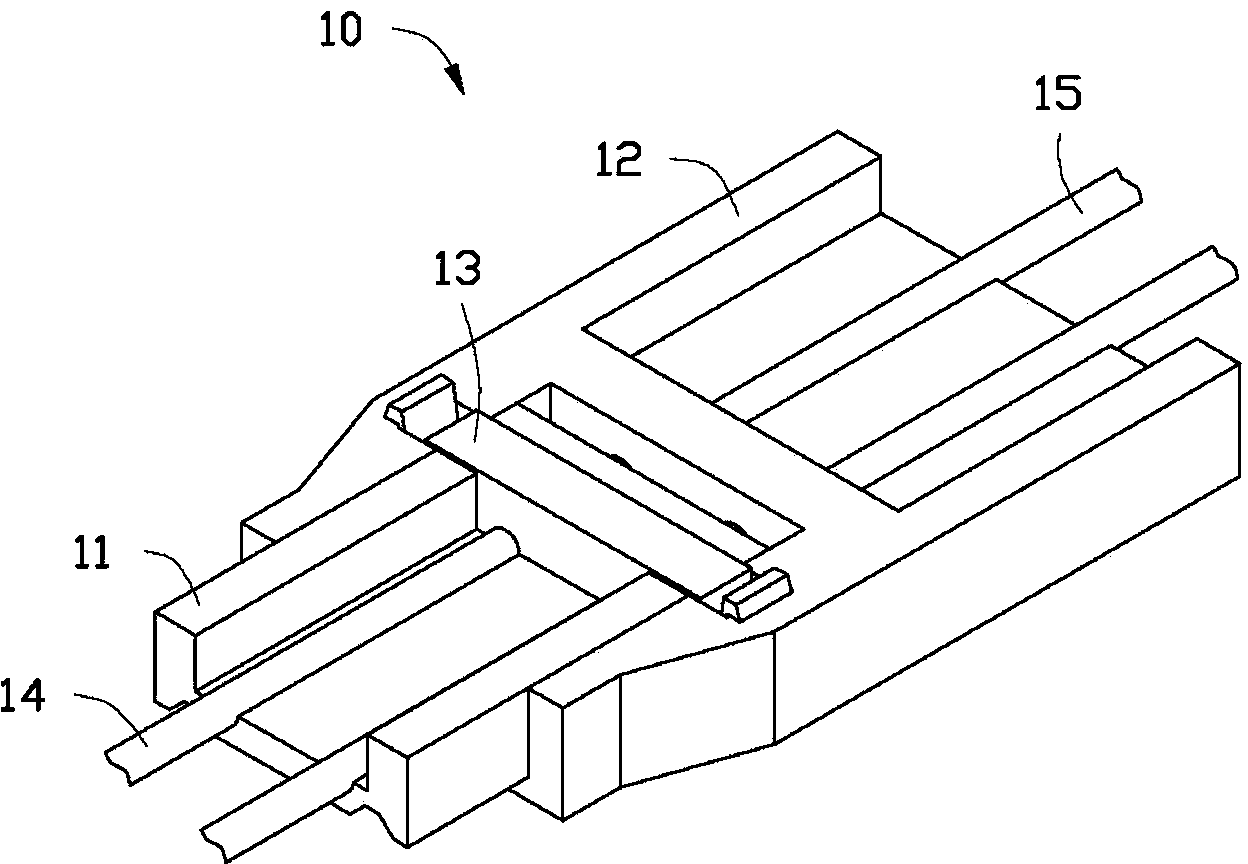

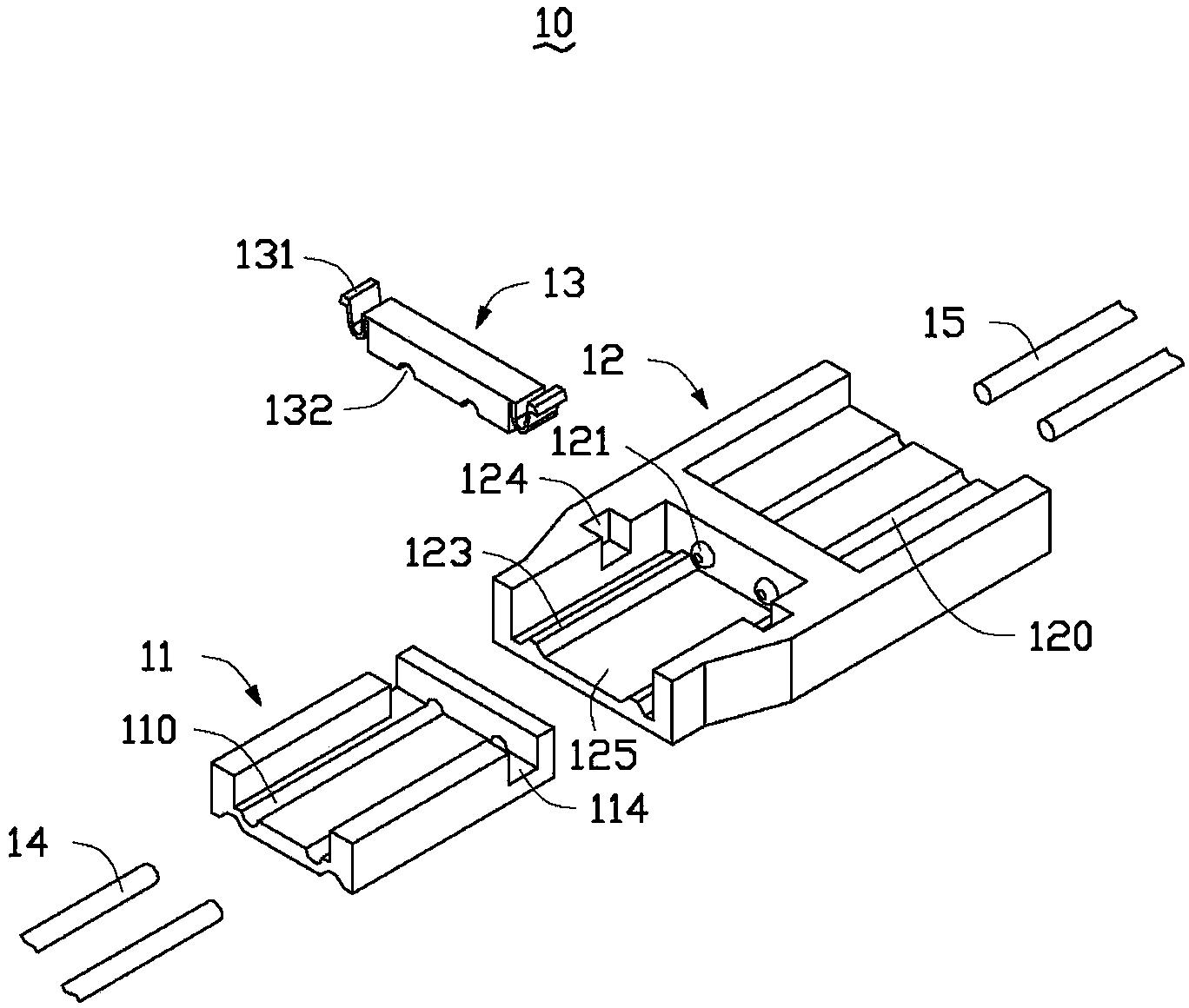

[0012] see figure 1 and figure 2 , the fiber coupling connector 10 provided by the embodiment of the present invention includes a plug 11, a receptacle 12, a fixing member 13, a first optical fiber 14 and a second optical fiber 15, and the fixing member 13 fixes the plug 11 on the receptacle 12 to realize the first optical fiber 14 Communication of optical signals with the second optical fiber 15.

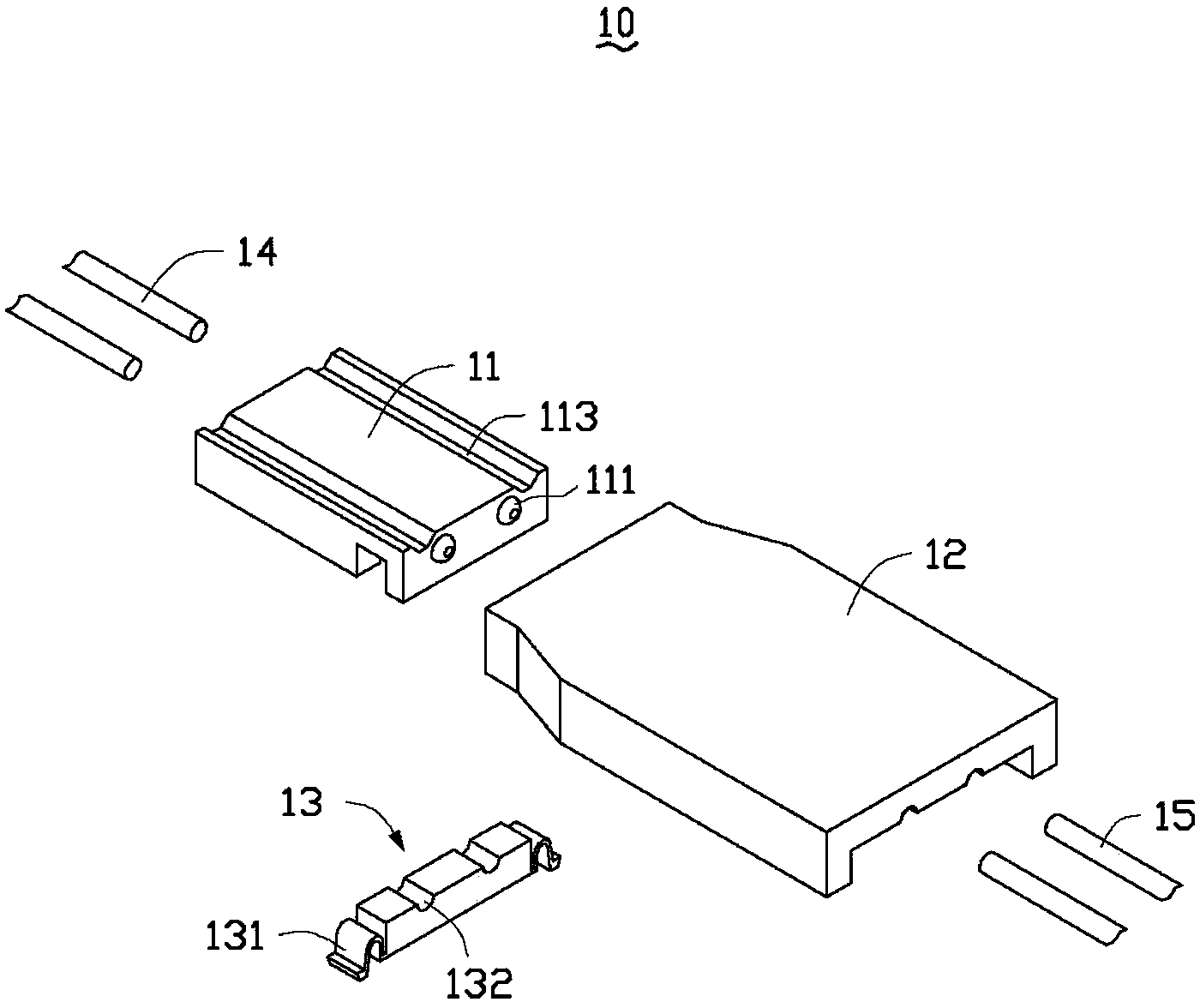

[0013] The plug 11 has two first accommodating grooves 110, two first lenses 111, two first slide rails 113 and two first openings 114, the first accommodating grooves 110 and the first slide rails 113 are arranged on the plug 11 The lengthwise directions of the two opposite surfaces are parallel to the optical axis of the first lens 111 , and the first accommodating groove 110 is located between the first openings 114 .

[0014] Please also refer to image 3 , the two first accommodating grooves 110 are arranged in parallel, the optical axes of the two first lenses 111 are par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com