An oxygen-free sintering method and device for aviation wire sealing

A wire sealing and sintering device technology, applied in the direction of insulating conductors/cables, etc., can solve the problems of conductor oxidation, lowering the quality grade of aviation wires, and high sintering temperature, avoiding oxidation, solving easy oxidation, and being easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

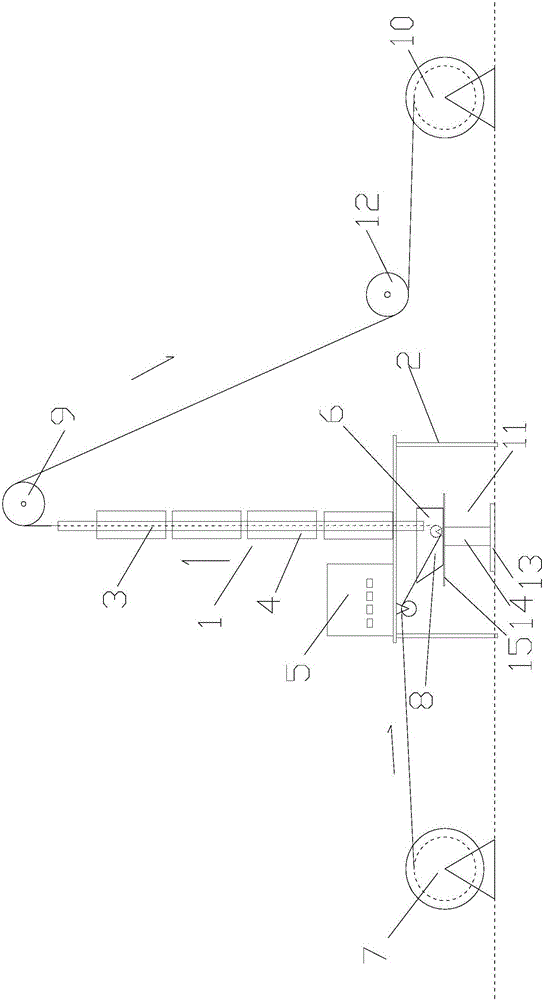

[0028] Install four 1.5-meter-long heating tiles 4 outside the 6.5-meter-long continuous stainless steel pipe 3, with 0.25 meters exposed at both ends of the stainless steel pipe 3. The heating tile 4 has its own temperature measurement mechanism, and the temperature measurement mechanism and the heating mechanism are connected by lead wires. Connected to the temperature control device 5, the above-mentioned device constitutes the sintering furnace 1, the sintering furnace 1 is placed vertically, so that the lower end is 500mm from the ground, the whole sintering furnace 1 is fixed by the bracket 2, and an alcohol tank 6 is placed under the sintering furnace 1, the alcohol tank 6 An inner guide wheel 8 is installed at the bottom of the tank. The alcohol tank 6 is placed on a support frame 11 that can move up and down. Fill the alcohol tank 6 with alcohol, and lift up the alcohol tank 6 until the surface of the alcohol liquid does not pass through the sintering furnace 1. The lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com