A dry-type shunt reactor protection method based on temperature and temperature rise monitoring

A technology of reactors and temperature sensors, which is applied in the direction of emergency protection circuit devices, electrical components, etc., can solve problems such as the protection problems of dry-type shunt reactors, and achieve the effects of simple operation, accurate criteria, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

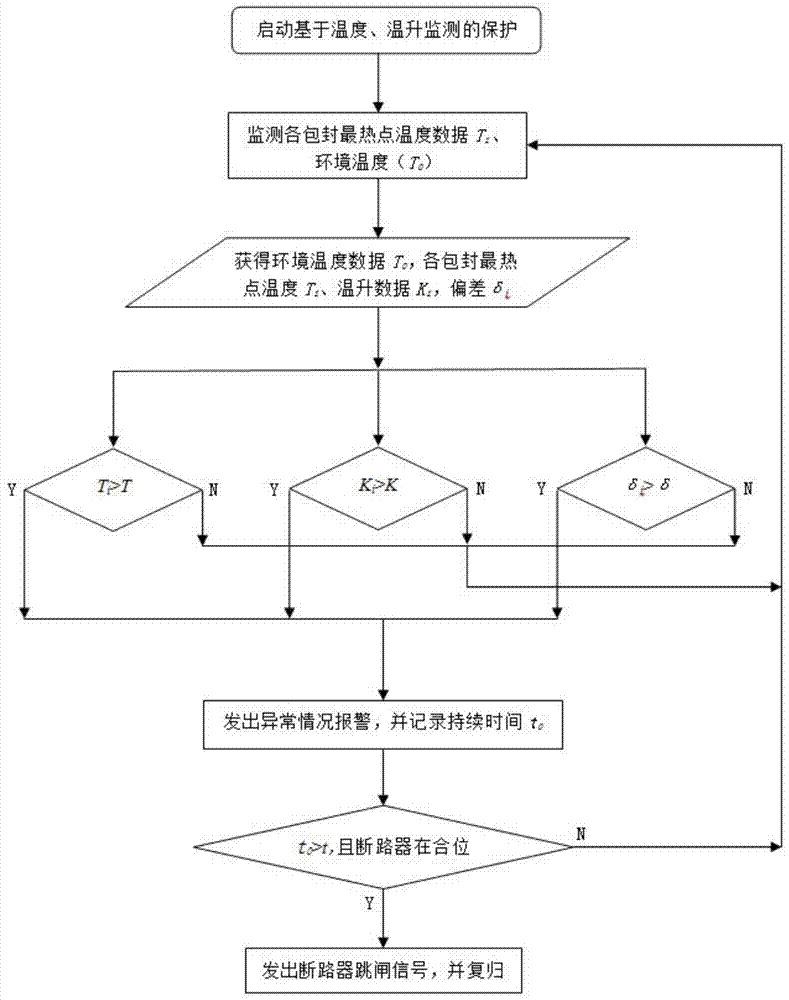

[0013] Attached below figure 1 , To further explain the present invention:

[0014] A dry-type shunt reactor protection method based on temperature and temperature rise monitoring. The feature of the present invention is that a temperature sensor is attached to the hottest position of each package of the dry-type shunt reactor to obtain each package (a total of n packages). ) Real-time hottest temperature data (T i , I = 1, 2, 3,..., n), and real-time monitoring of the ambient temperature (T 0 ), so as to obtain the real-time temperature of each envelope of the dry shunt reactor (T i , I = 1, 2, 3,..., n) and temperature rise data (K i = T i -T 0 , I=1, 2, 3,...,n). The real-time temperature (T i , I = 1, 2, 3,..., n) and the temperature setting value (T) to identify the abnormal state and give an alarm; through each package real-time temperature (T i , I = 1, 2, 3,..., n) lateral deviation The comparison with the set value (δ) identifies the abnormal state and gives an alarm; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com