Carrier structure for an armrest of a vehicle

A supporting structure and vehicle technology, applied to the special position of the vehicle, handrails, vehicle parts, etc., can solve the problems of heavy weight and high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

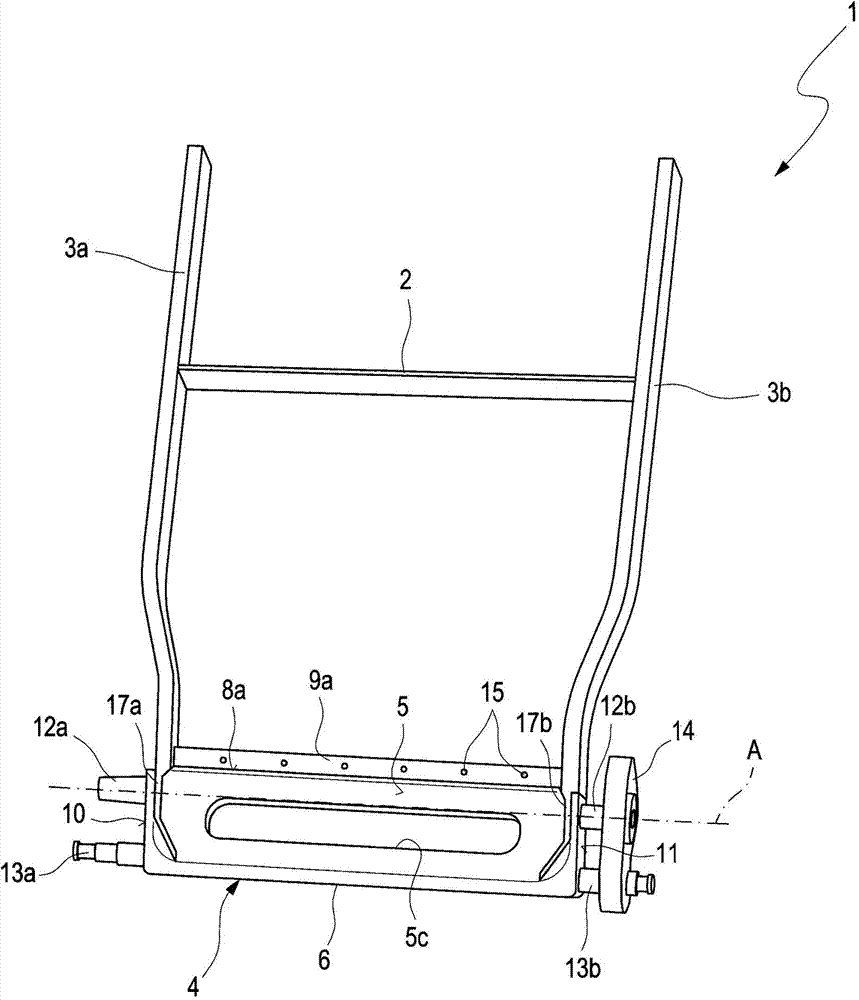

[0027] According to the basis of the present invention figure 1 The support structure 1 is used to receive the armrest body (not shown) that is used to form the vehicle armrest that can swing. Also connected by crossbar 2. The crossbeam 4 is articulated pivotally about a pivot axis A to a frame (not shown) of the vehicle via two pivot bearings 12a and 12b. Two further clamping levers 13 a and 13 b are likewise formed on the cross member 4 , wherein the clamping lever 13 b is operatively connected to the crash rocker 14 in order to prevent an uncontrolled upward pivoting of the armrest at high vehicle accelerations. Such a crash pendulum is known to those skilled in the art, and thus will not be described in detail here.

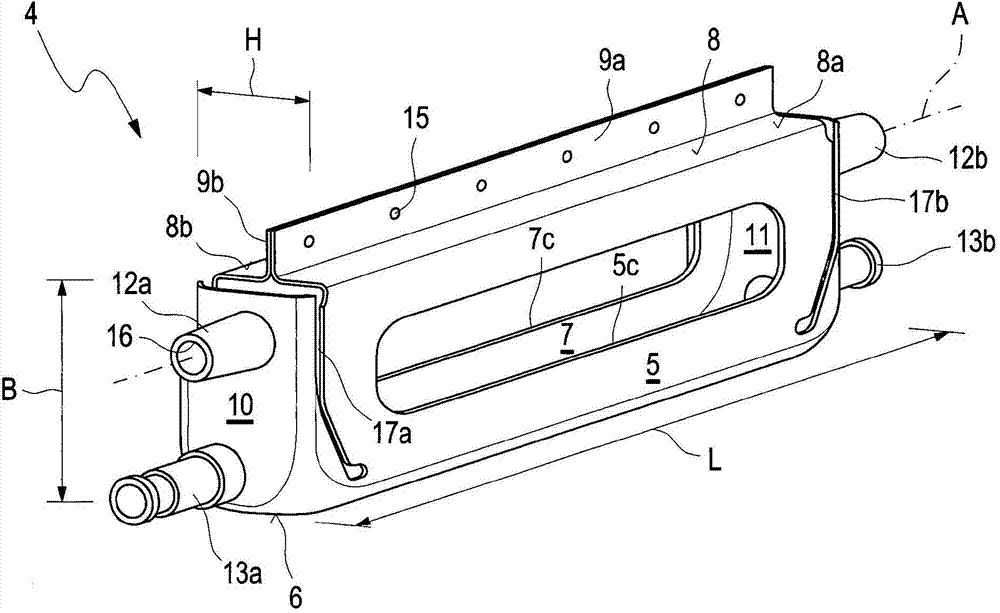

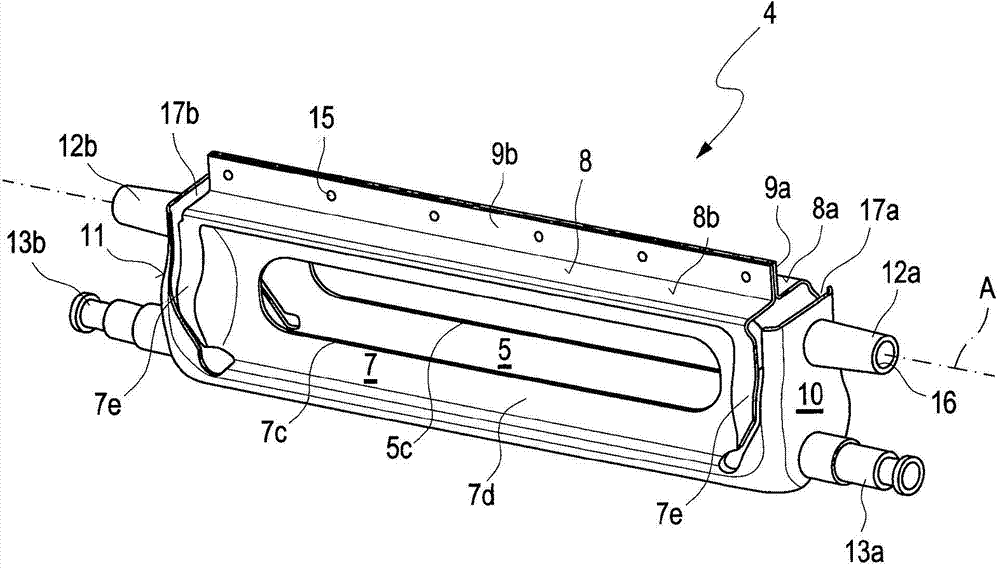

[0028] figure 2 , 3 4 and 4 show the beam 4 in different perspectives, wherein the cuboid shape of the beam can be seen. The cuboid cross member 4 is produced from a flat steel sheet, which is essentially designed as a cuboid-shaped development of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com