A squirrel-cage cylindrical linear motor

A linear motor, cylindrical technology, applied in the direction of electrical components, electromechanical devices, etc., can solve the problems that cannot meet the requirements of modern control systems, and achieve the effects of broad market prospects, long service life, easy loading and unloading, and post-maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

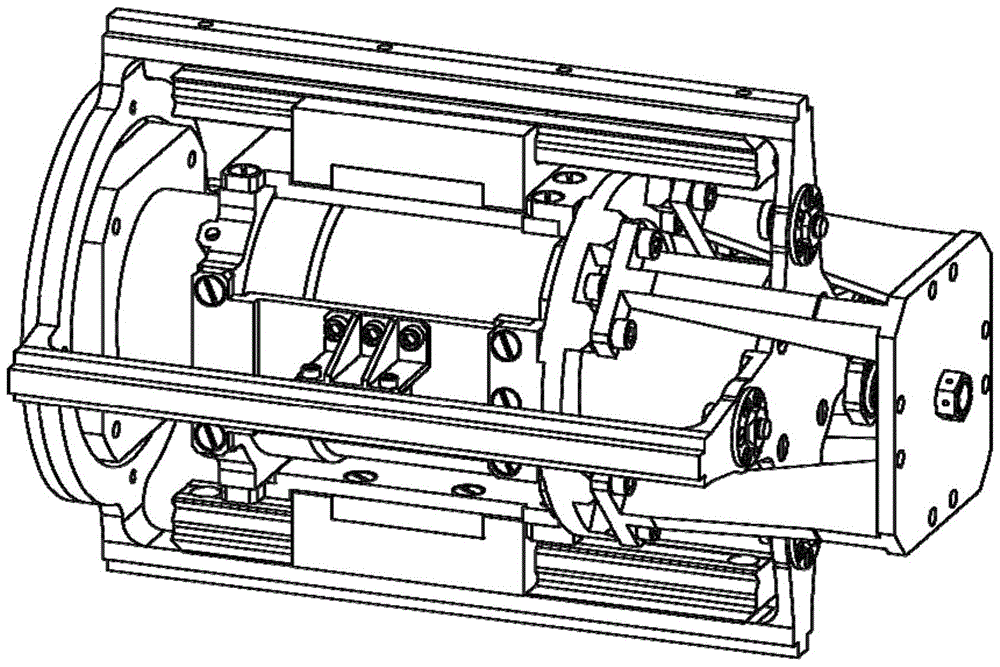

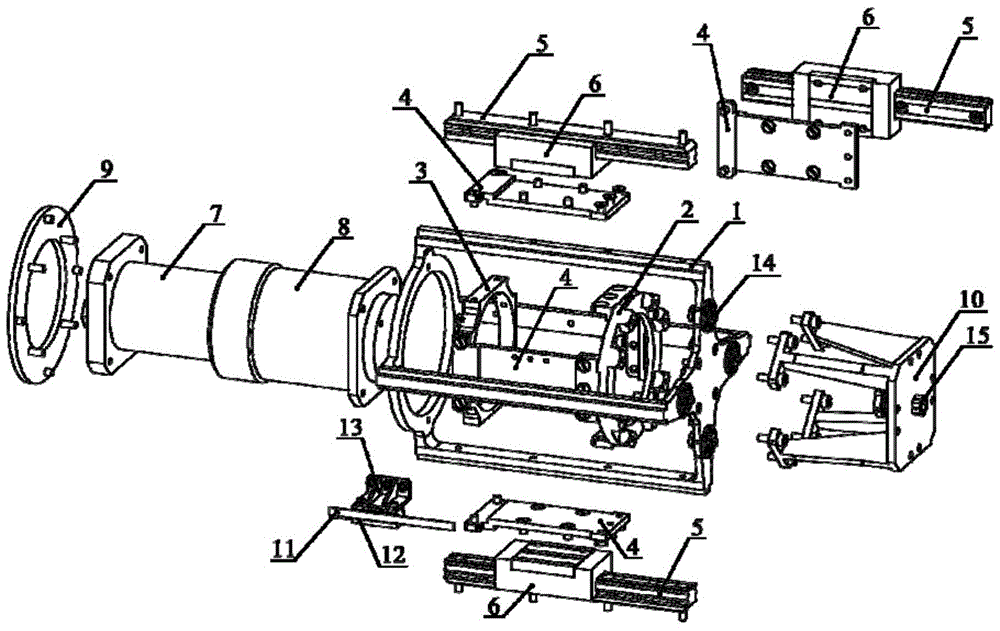

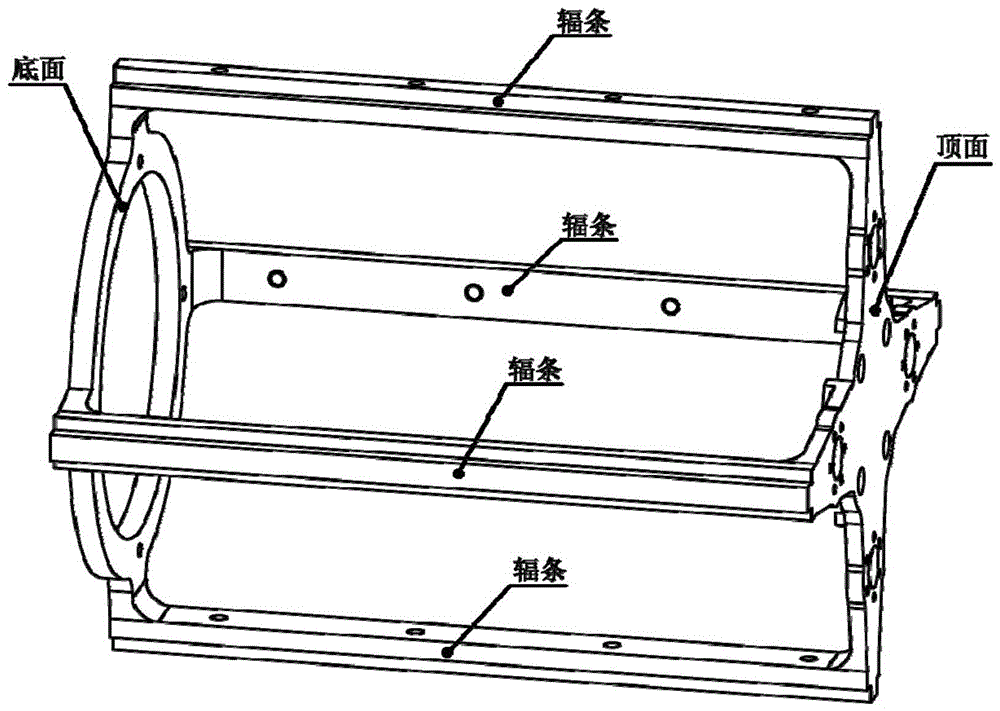

[0039] This embodiment takes a squirrel-cage cylindrical linear motor as an example, such as Figure 1 to Figure 5 As shown, the squirrel-cage cylindrical linear motor provided by the embodiment of the present invention includes: a squirrel cage 1, a cage 2, a clamp 3, a connecting plate 4, a guide rail 5, a slider 6, a stator 7, a mover 8, Support plate 9 , push seat 10 , scale 11 , reading head 12 , connecting frame 13 , inner buffer 14 , and outer buffer 15 . There are four spokes spaced between the annular end face and the cross-shaped end face of the squirrel cage 1 arranged in parallel along its axis direction. On the axis, the mover 8 is sleeved on the outside of the stator 7 for linear reciprocating motion; one end of the stator 7 and the annular end face of the squirrel cage 1 are fixedly connected through the annular suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com