Feed expansion machine mold

An extruder and feed technology, applied in the direction of feed, food science, application, etc., can solve the problems of screw sleeve blockage, inability to adjust the barrel pressure, high temperature of the expansion sleeve, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

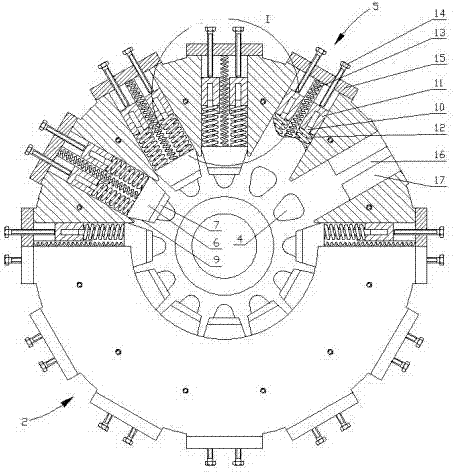

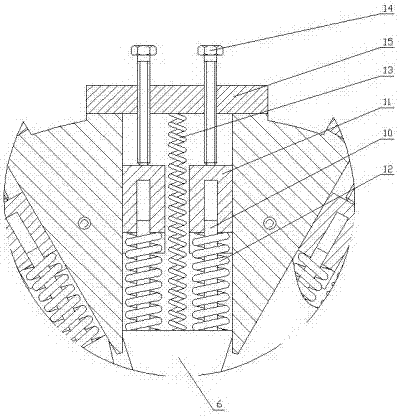

[0019] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

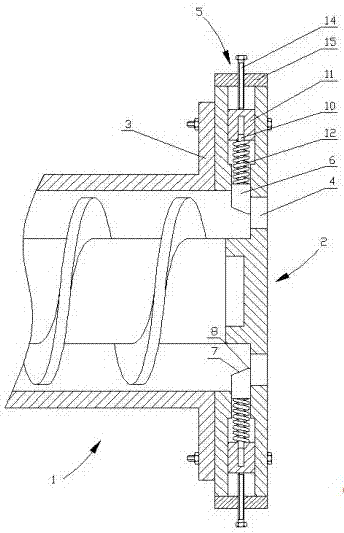

[0020] Such as Figure 1-3 As shown, the present embodiment is a mold for a feed extruder, including a disc body 2 arranged at the end of the screw extruding mechanism 1, and a flange 3 is arranged at the end of the screw extruding mechanism 1, and the flange 3 is connected to the The disc body is connected by bolts.

[0021] The disc body 2 is provided with a die hole 4, and the die hole 4 axially corresponds to the cavity of the screw extrusion puffing mechanism 1 and is evenly distributed on the disc body 2; the end of the die hole 4 facing the axis of the screw extrusion puffing mechanism 1 is narrow, and the back One end is wide toward the axis line of the screw extrusion puffing mechanism 1; the die holes 4 are evenly distributed around the axis line of the screw extrusion puffing mechanism 1.

[0022] The disc body 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com