High-temperature puffing device for producing high-thermal-conductivity natural graphite film

A technology of high-temperature expansion and natural graphite, which is applied in the direction of inorganic chemistry, carbon compounds, chemical instruments and methods, etc., can solve the problems of reducing the yield of worm graphite, secondary expansion, worm graphite burning, etc., and achieve uniform expansion temperature field Easy to control, guaranteed puffing quality, simple and practical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

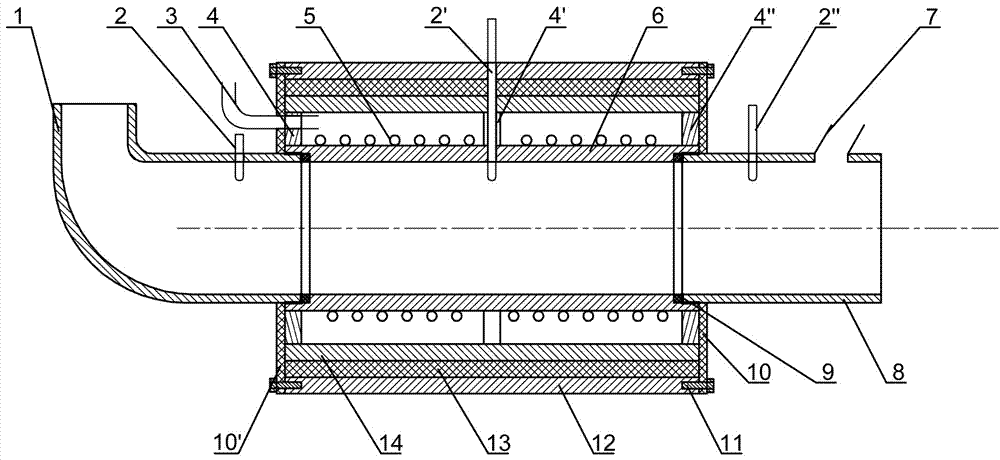

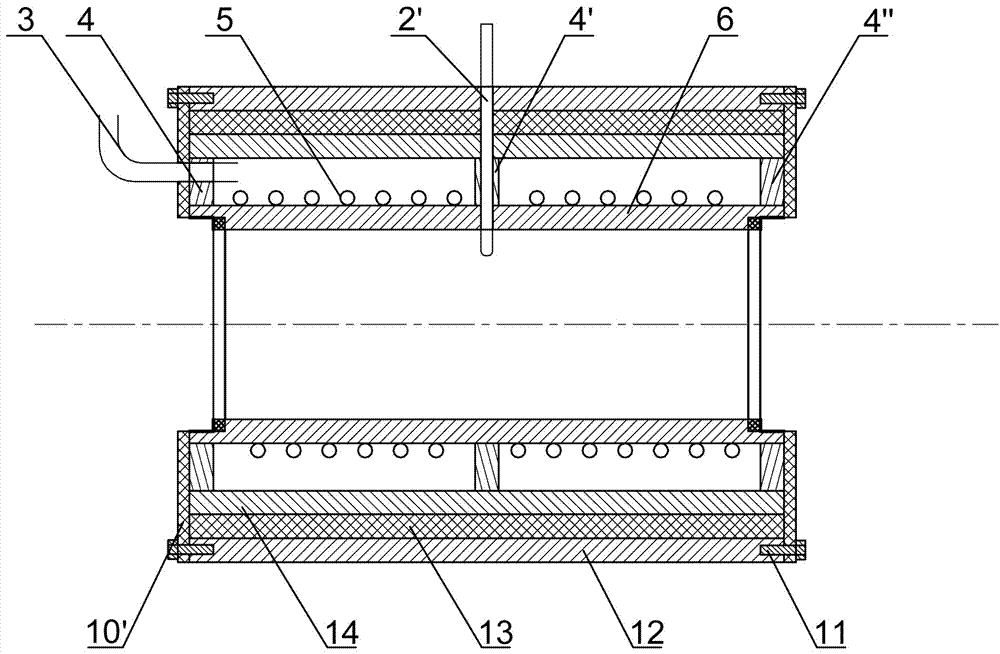

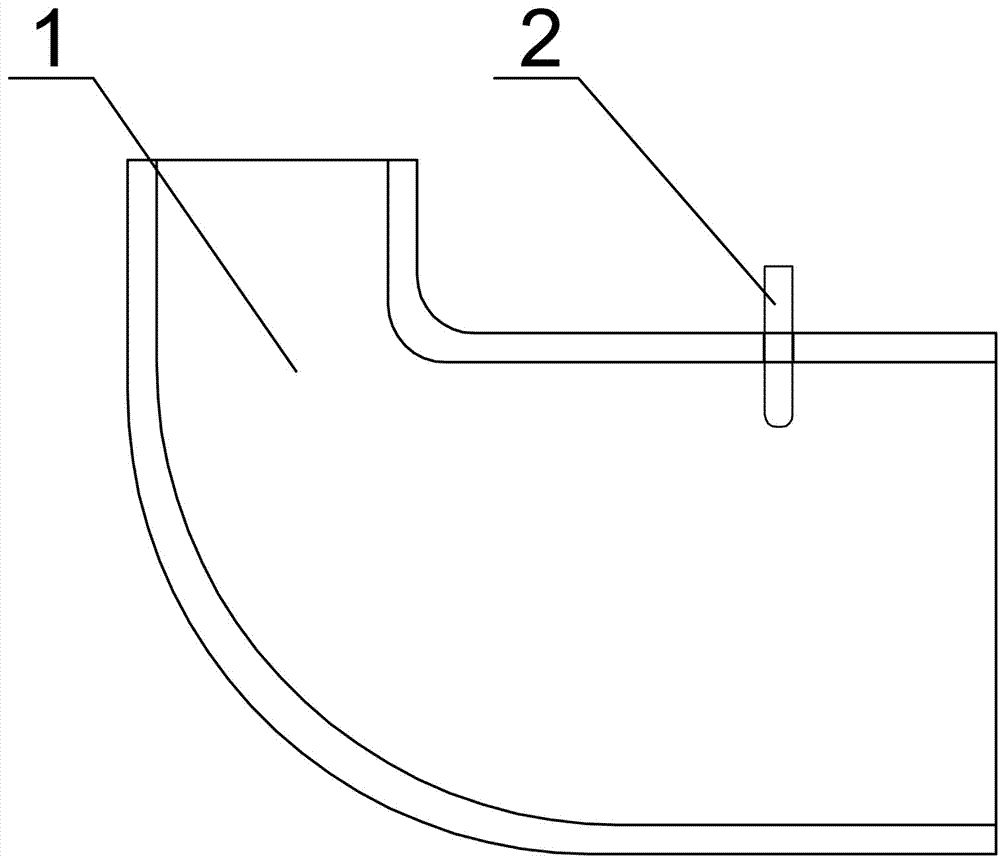

[0022] Such as Figure 1-4 , a high-temperature expansion device for the production of high-thermal-conductivity natural graphite film, which includes a high-temperature expansion tube 6, the outside of the high-temperature expansion tube 6 is wound with a molybdenum wire 5 for heating it, and the outside of the high-temperature expansion tube 6 is passed through a ceramic The support rings 4, 4', 4'' are set with a ceramic outer tube 14, and the outside of the ceramic outer tube 14 is set with a graphite felt 13, and the outside of the graphite felt 13 is set with a metal shell 12; the metal shell Both ends of the body 12 are fixedly equipped with metal-asbestos sealing end caps 10, 10'; one end of the high-temperature expansion pipe 6 is equipped with a feed pipe 8, and the other end is equipped with a discharge pipe 1; the discharge pipe 1 1. Thermocouples 2, 2' and 2'' are respectively installed on the high temperature expansion pipe 6 and the feed pipe 8; the feed port 7 ...

Embodiment 2

[0029] A high-temperature expansion device for the production of high-thermal-conductivity natural graphite film, which is mainly composed of a discharge pipe 1, thermocouples 2, 2', 2'', pipe interface 3, ceramic support rings 4, 4', 4'', molybdenum wire 5. High-temperature expansion pipe 6, feed pipe 8, asbestos gasket 9, metal-asbestos sealing end cap 10, 10', bolt 11, metal shell 12, graphite felt 13, and ceramic outer pipe 14, etc. made.

[0030] Further, the materials of the discharge pipe 1, the high-temperature expansion pipe 6 and the feed pipe 8 are all high-purity quartz tubes, and their inner diameters are all φ60. The wall thickness of the discharge pipe 1 and the feed pipe 8 is 6 mm, and the length is 500 mm. The wall thickness and length of the expansion pipe 6 are 10mm and 2500mm respectively; one end of the high-temperature expansion pipe 6 is assembled with the feed pipe 8 in a nested form, and the other end is assembled with the discharge pipe 1 in a nested ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com