Powder drink bulking machine

An extruder and beverage technology, applied in food forming, food science, application and other directions, can solve the problems of uneven heating, poor puffing effect, and difficulty in assembly line operation, so as to ensure the puffing quality, reduce wear, and easily metamorphic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

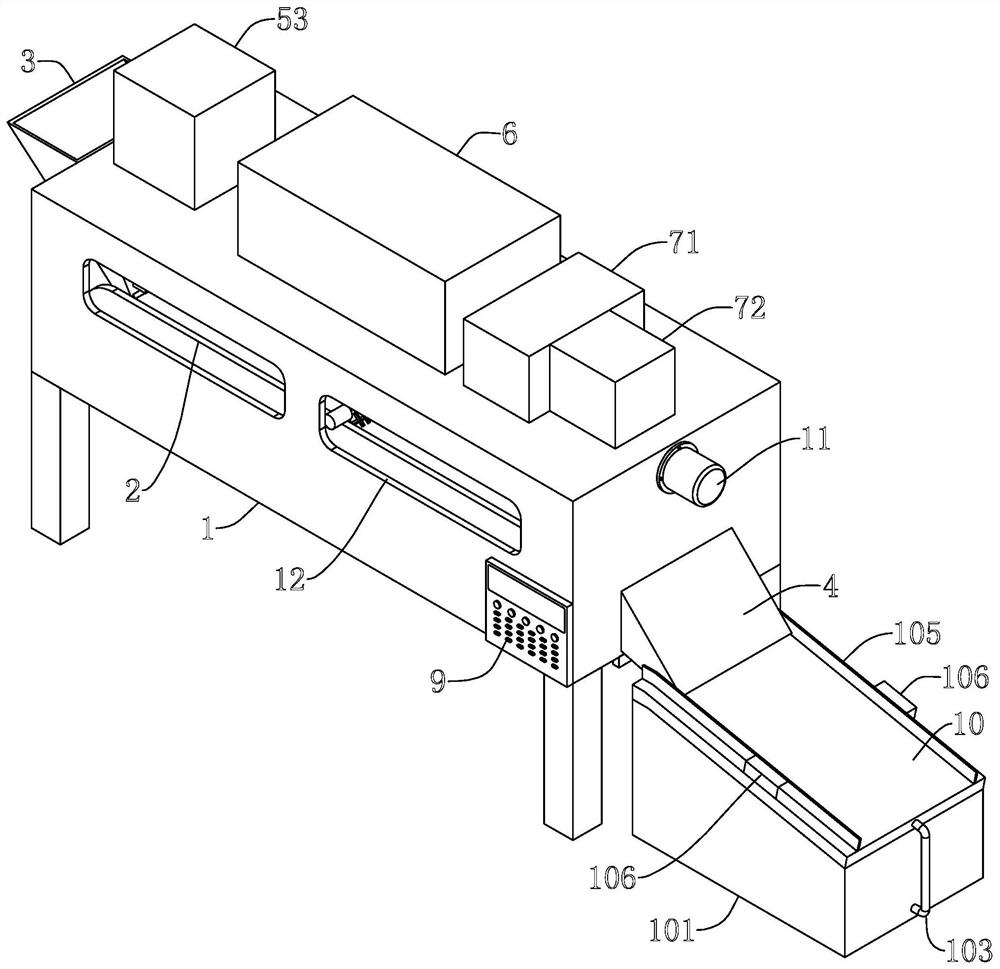

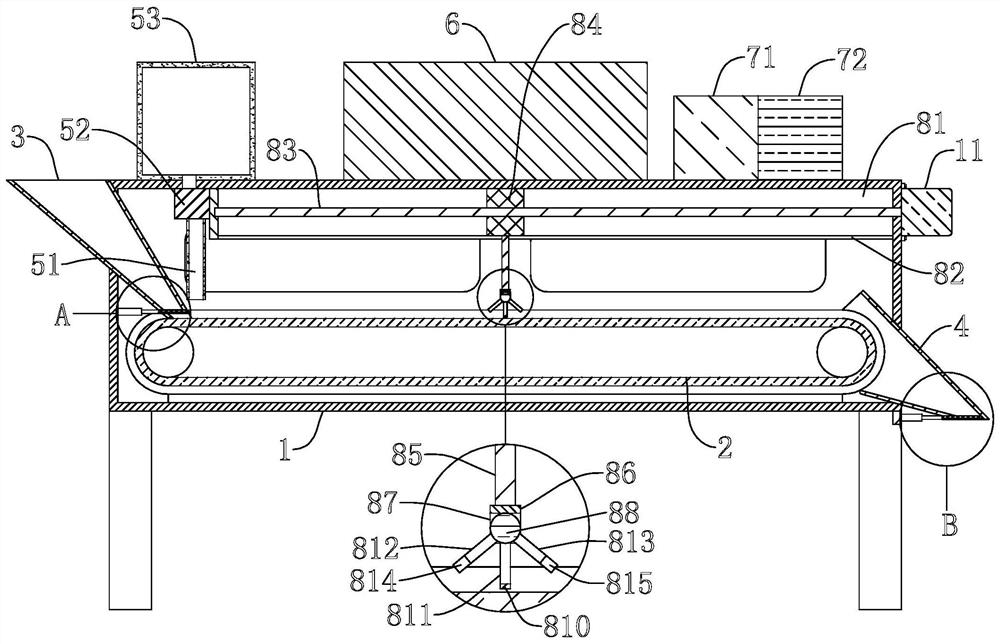

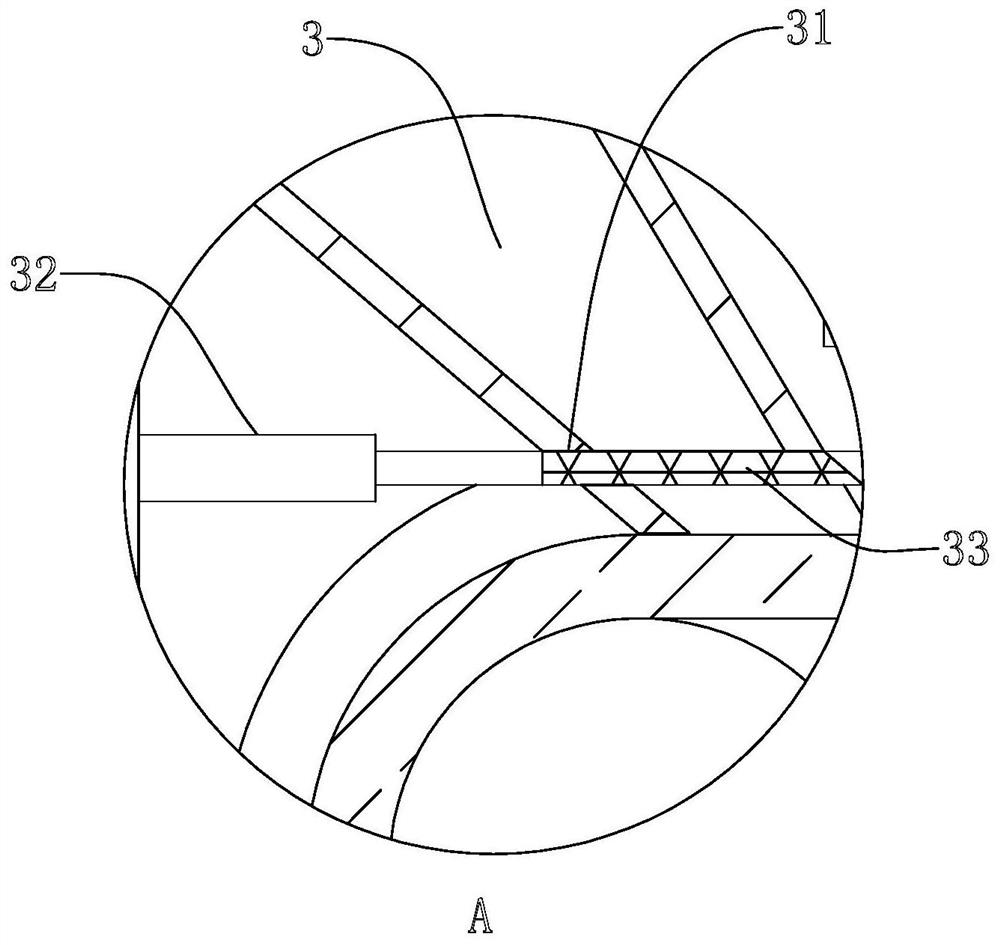

[0030] Embodiment, a kind of powder beverage extruder, such as Figure 1 to Figure 6As shown, it includes a hollow main body 1, and a conveyor belt 2 is horizontally arranged in the main body 1, and the conveyor belt 2 is arranged in a left-right direction. Located above the left end of the conveyor belt 2, the first automatic door for sealing the feed port 3 is provided on the feed port 3, and the right side of the main body 1 is communicated with a discharge port 4 inclined downward to the right, and the discharge port 4 is located at Below the right end of the conveyor belt 2, the discharge port 4 is provided with a second automatic door for sealing the discharge port 4, the main body 1 is provided with a dust suction port 51 above the left side of the conveyor belt 2, and the upper end of the dust suction port 51 communicates with a Air pump 52, the air pump 52 is located at the upper end in the main body 1, the upper end of the main body 1 is provided with a first water t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com