Crop expansion treatment system

A technology for puffing and crops, which is applied in agriculture, food science, agricultural machinery and equipment, etc., can solve the problems of time-consuming, laborious, low precision, low efficiency, etc., and achieve the effect of ensuring the quality of puffing, improving efficiency, and improving the accuracy of adding ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

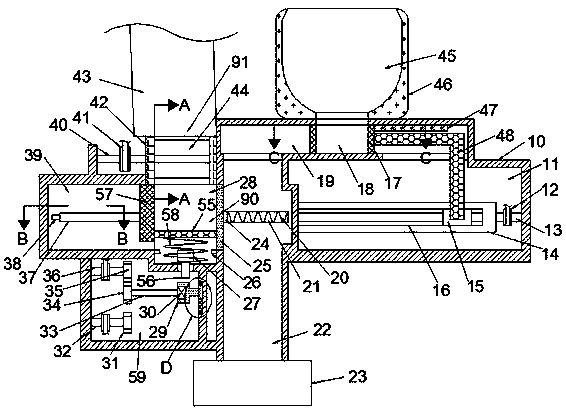

[0021] Combine below Figure 1-5 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

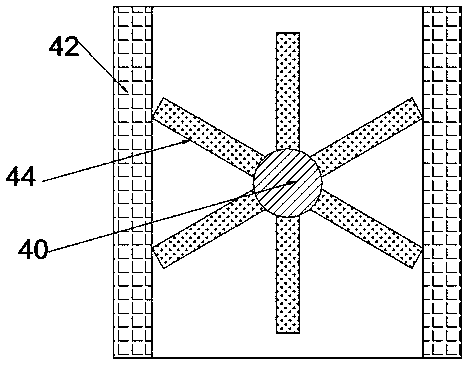

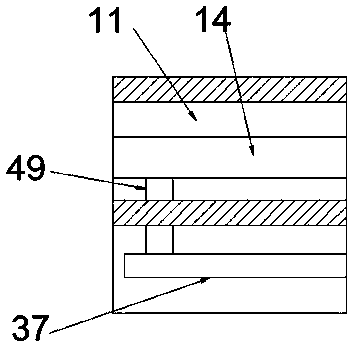

[0022] A crop puffing processing system described in conjunction with accompanying drawings 1-5 mainly includes a processing box 10 and a material storage chamber 28 arranged in the processing box 10, and the processing box 10 is installed on the harvester and moves synchronously with the harvester , the upper side of the storage chamber 28 communicates with the harvester straw outlet 43 through the connecting pipe 42, the connecting pipe 42 is provided with a valve mechanism 91, and the storage chamber 28 is provided with a detection mechanism 90;

[0023] After the harvester is turned on, the valve mechanism 91 is opened, and the crushed stalks enter the storage chamber 28, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com