Chestnut Roaster

A technology for roasting machine and chestnut, applied in the fields of application, food processing, food science, etc., can solve the problems of inconvenient peeling, easy overheating and bursting, and non-constant heating, so as to accurately grasp the temperature and time, meet the needs of commercialization, The effect of roasting quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

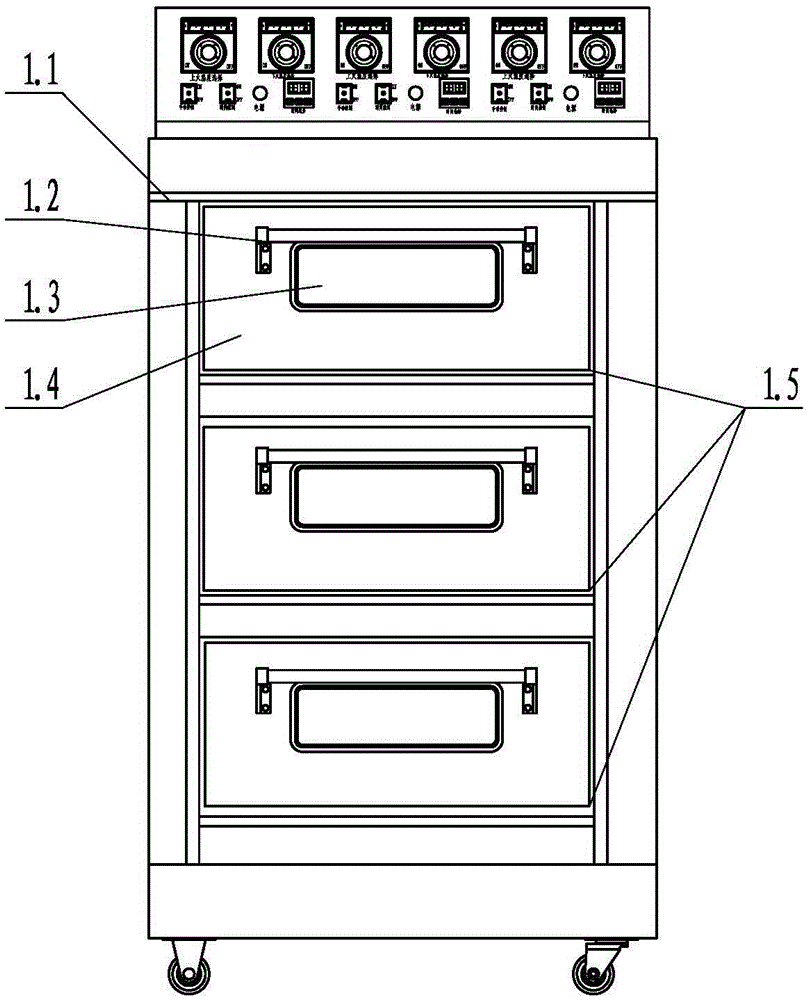

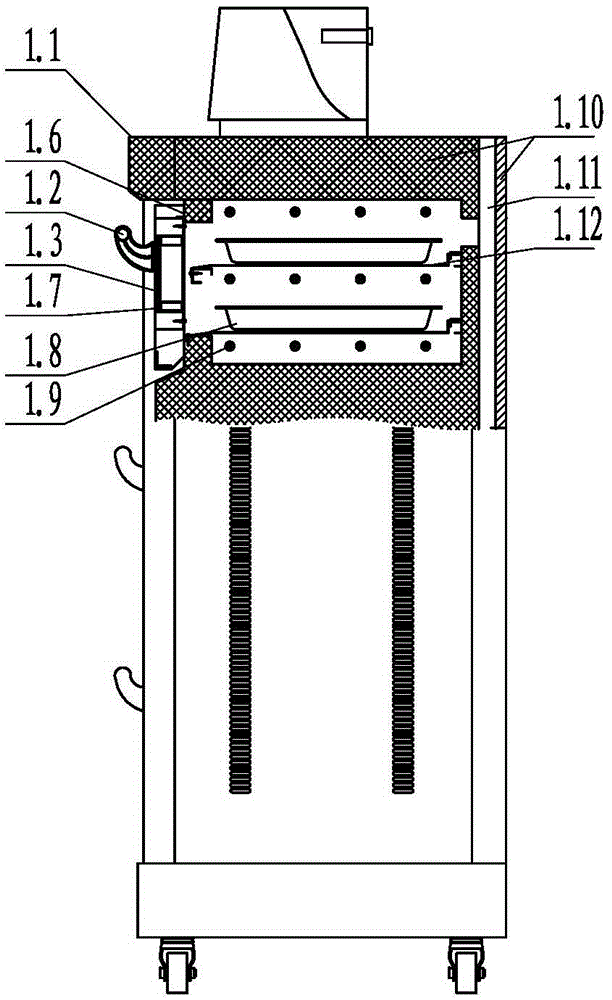

[0068] Such as figure 1 and 2 As shown, in the chestnut roasting machine provided with multi-layer baking tray 1.8 according to the present invention, more than one baking chamber 1.5 is arranged on the baking machine body 1.1, and more than two layers of brackets 1.12 are arranged in each baking chamber 1.5, and each layer More than one baking pan 1.8 is placed on the bracket 1.12, and a group of heating tubes 1.9 is arranged under each bracket 1.12.

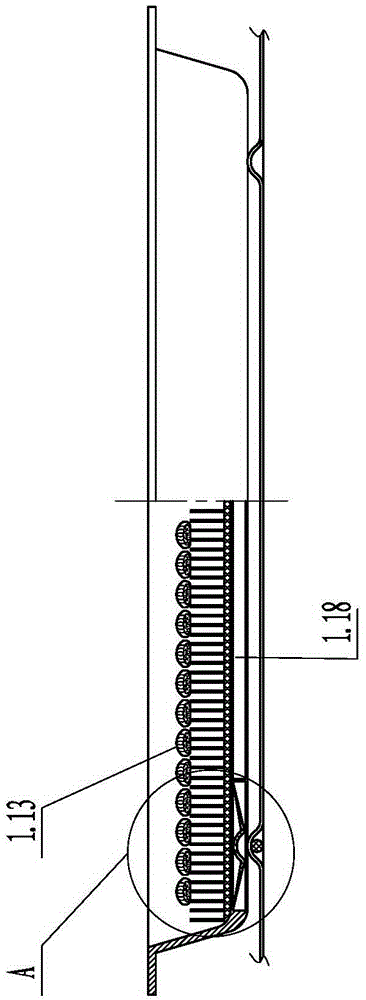

[0069] Such as figure 2 and 3 As shown, a grill magnetic positioning device is provided between the grill 1.8 and the bracket 1.12, and the grill magnetic positioning device includes a bracket positioning part and a grill positioning part. The structure of the positioning part of the bracket is: a convex positioning point is set on the bracket 1.12, and a magnet 1.17 is placed in the convex positioning point; A disc-shaped magnetic disk 1.16 is arranged in the heat preservation cavity 1.18, the periphery of the magnetic di...

Embodiment 2

[0075] Such as Figure 8 and 9As shown, more than two roasting chambers 2.5 are set on the roasting machine body 2.1, and a smoke exhaust port 2.9 is provided at the rear of the roasting chamber 2.5, and the smoke exhaust port 2.9 is connected to the smoke exhaust elbow 2.10, and the bending angle of the smoke exhaust elbow 2.10 is 45-90 degrees. The moisture of raw chestnuts during roasting can be directly discharged to the outside through the smoke exhaust elbow 2.10, which facilitates the roasting of chestnuts and does not cause chestnuts to be stuffy due to too much moisture. Hard and crisp, easy to peel and eat. The bending angle of the smoke exhaust elbow 2.10 is 45-90 degrees, which can prevent hot air from directly spraying out and causing heat damage to the human body and surrounding objects.

[0076] Such as Figure 10 As shown, the smoke exhaust elbow 2.10 includes a joint 2.13 and an intubation tube, and the intubation sequence includes the insertion section 2....

Embodiment 3

[0083] Such as Figure 16 and 17 As shown, more than two baking chambers 3.11 are arranged on the baking machine body 3.1, an oven door 3.4 is installed on the baking chamber 3.11, and a heating pipe 3.12 is arranged in the baking chamber 3.11. A buzzer 3.13 is installed on the roaster body 3.1, and the buzzer 3.13 includes an alarm device 3.19 and a control device 3.20. Such as Figure 19 As shown, the control device 3.20 is respectively connected to the control timer 3.21, the temperature controller 3.23 and the door closure detector 3.22; when the timing time is reached, or the temperature exceeds the standard, or the oven door 3.4 is not closed, the control device 3.20 can start Alarm device 3.19 sends alarm sound.

[0084] The temperature controller 23 includes a temperature control system, the temperature control system is respectively connected to the oven temperature sensor, the electrical box temperature sensor and the flue temperature sensor, and the oven temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com