Rotatable cooling and cleaning mechanism for shooting nozzle

A technology of sand shooting machine and overturning bracket, applied in the field of molding machine components, can solve the problems of short curing time, low efficiency, affecting the factory environment, etc., and achieve the effect of preventing sand cores from flying around and facilitating cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

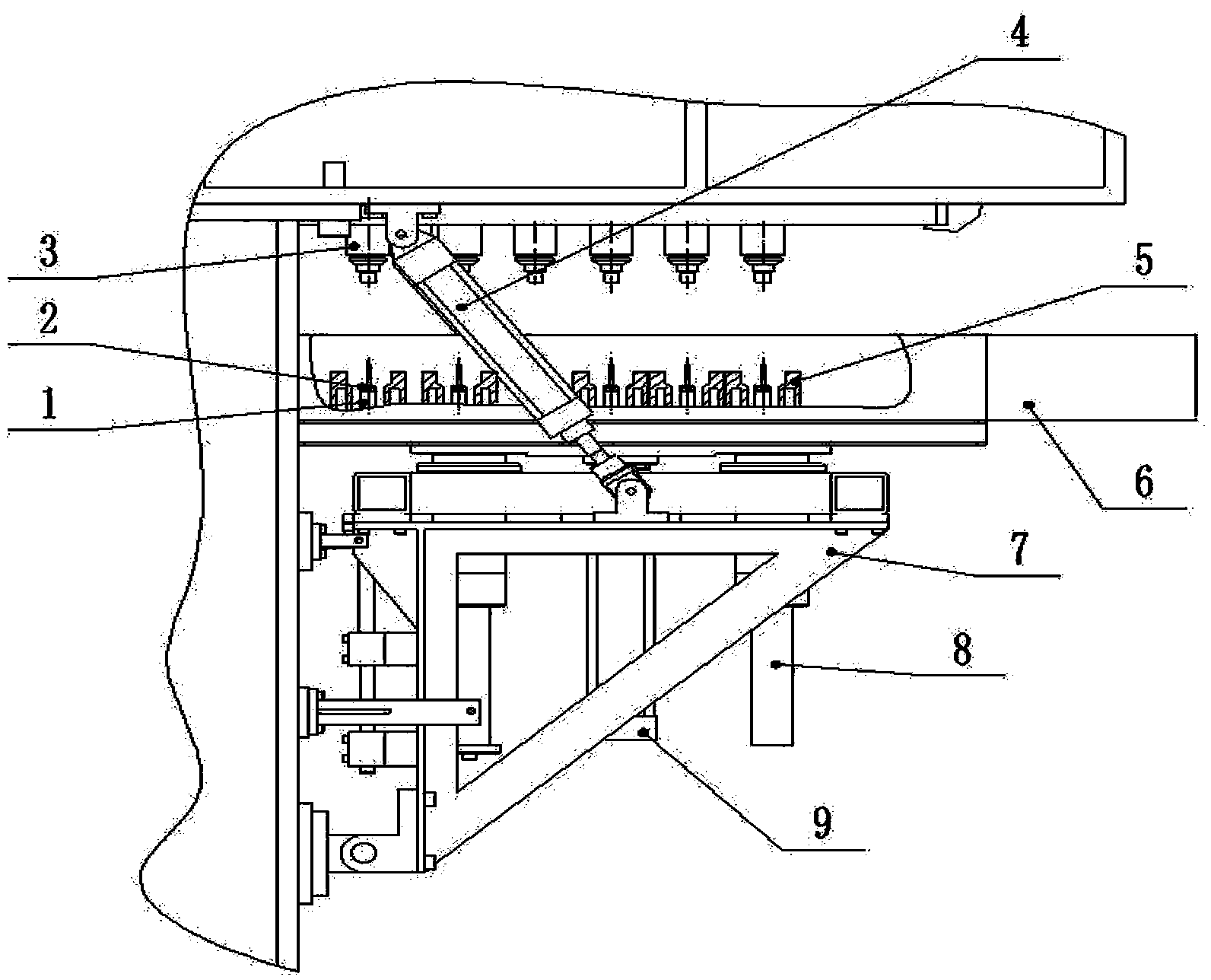

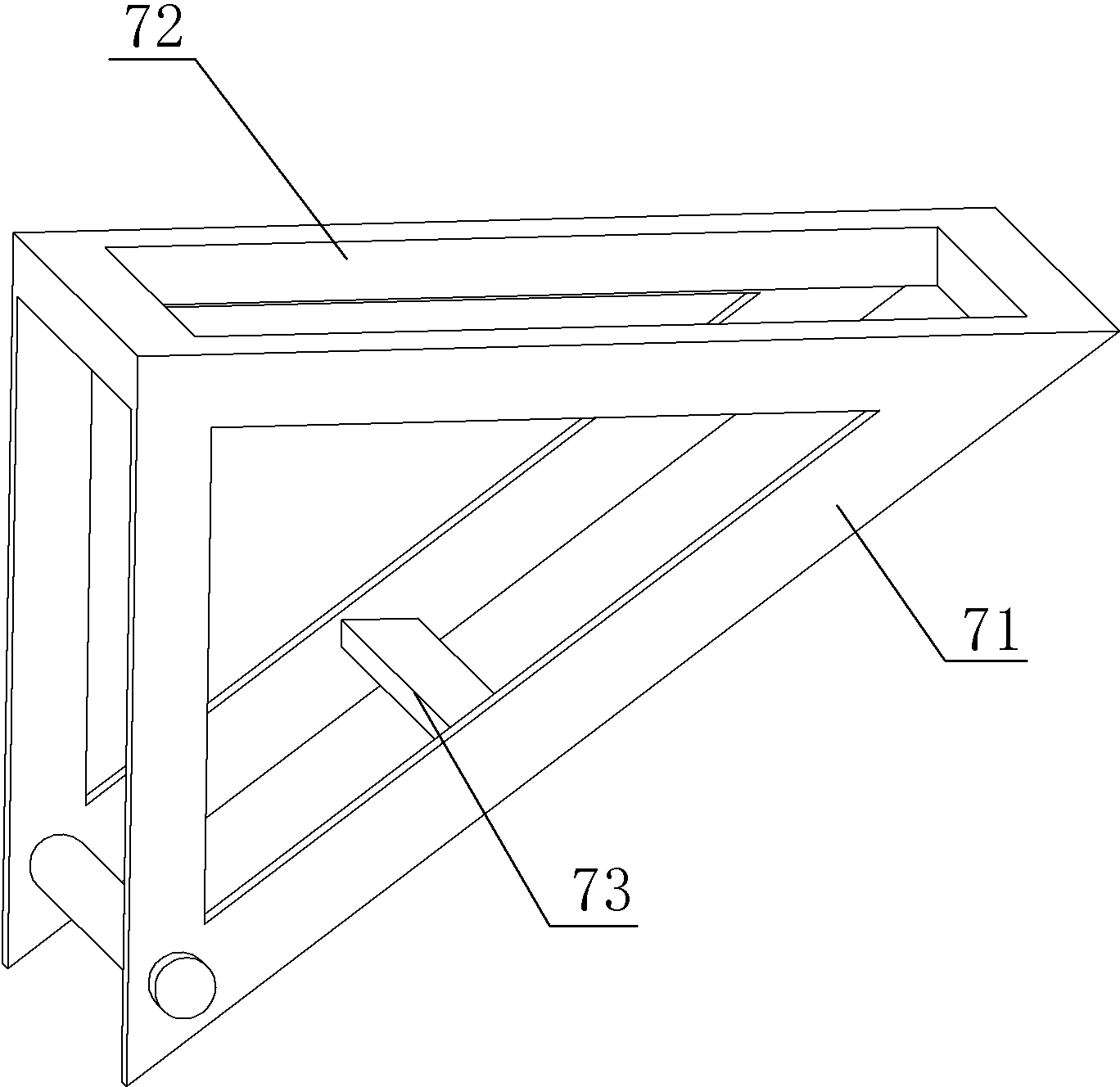

[0014] The reference signs in the drawings of the specification include: 1. Piercing nails; 2. Rubber pads; 3. Nozzles; 4. Telescopic oil cylinders; 5. Nozzle cooling jackets; , guide shaft; 9, jacking oil cylinder; 71, triangular plate; 72, rectangular frame; 73, horizontal plate.

[0015] The embodiment is basically as figure 1 , figure 2 Shown: The tiltable nozzle cooling and cleaning mechanism is located under the nozzle guide rail of the sand blasting machine. Several nozzles 3 of the sand-shooting machine are fixed on a slide plate, and the slide plate is slidably matched with the nozzle guide rail. When the nozzle 3 finishes shooting sand, it moves horizontally to the nozzle cooling and cleaning mechanism directly above the nozzle through the guide rail.

[0016] The tiltable nozzle cooling and cleaning mechanism includes a triangular frame 7, a telescopic oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com