A cloth grabbing mechanism

A grasping mechanism and cloth technology, applied in the field of knitting machinery, can solve the problems of uneven tension, wrinkles, offset, affecting work efficiency and finished product quality, etc., and achieve the effect of simple mechanism structure, smooth cloth, and stable grasping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

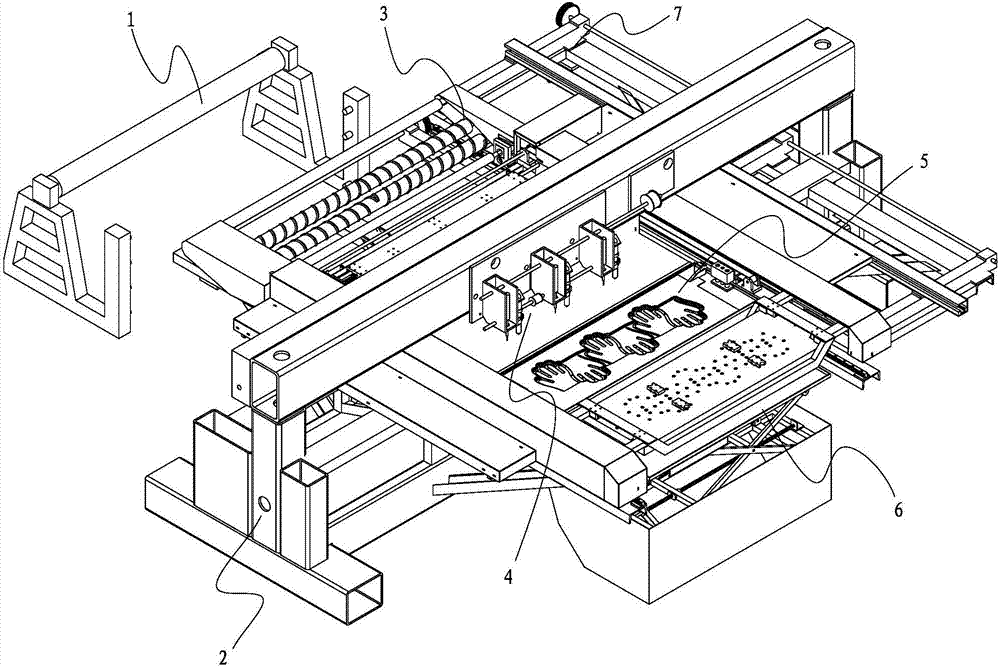

[0023] The cloth grabbing mechanism described in this embodiment is applied to an integrated glove machine, such as figure 1 As shown, the glove mechanism includes a cloth conveying mechanism 1, a machine base 2, and a cloth alignment mechanism 3 arranged on the machine base 2, a cloth embroidery mechanism 4, a cloth grabbing mechanism 5, a glove placing mechanism 6, and a driving mechanism 7 And the control mechanism, etc., the cloth can be cut and sewn finished gloves through the work of the above-mentioned mechanism.

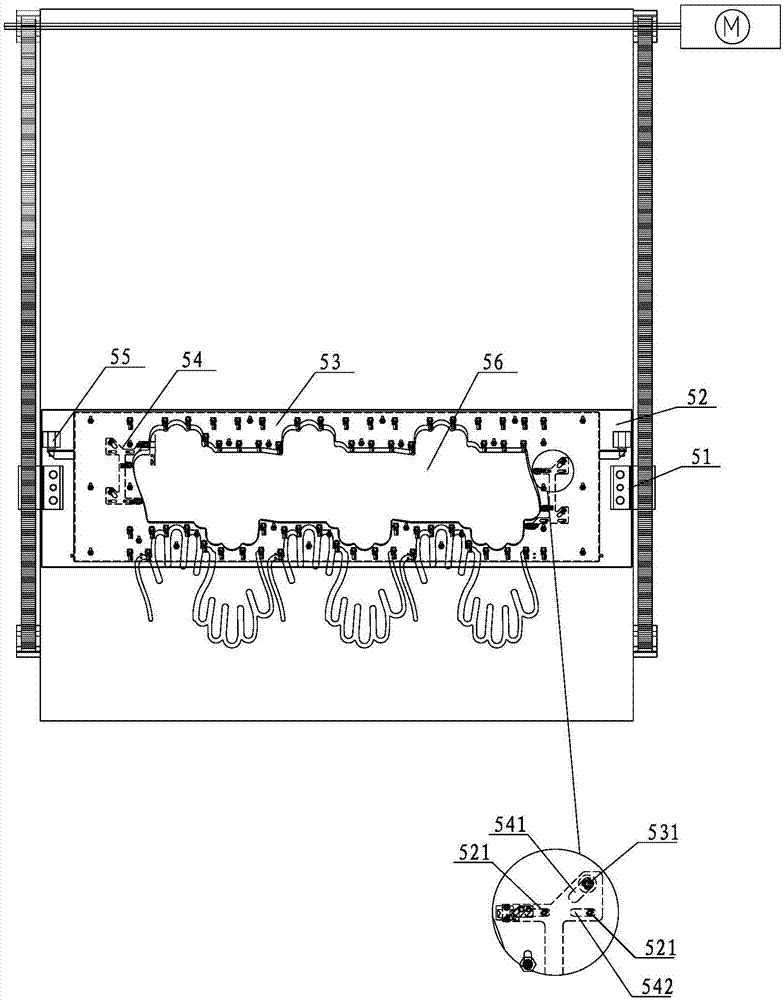

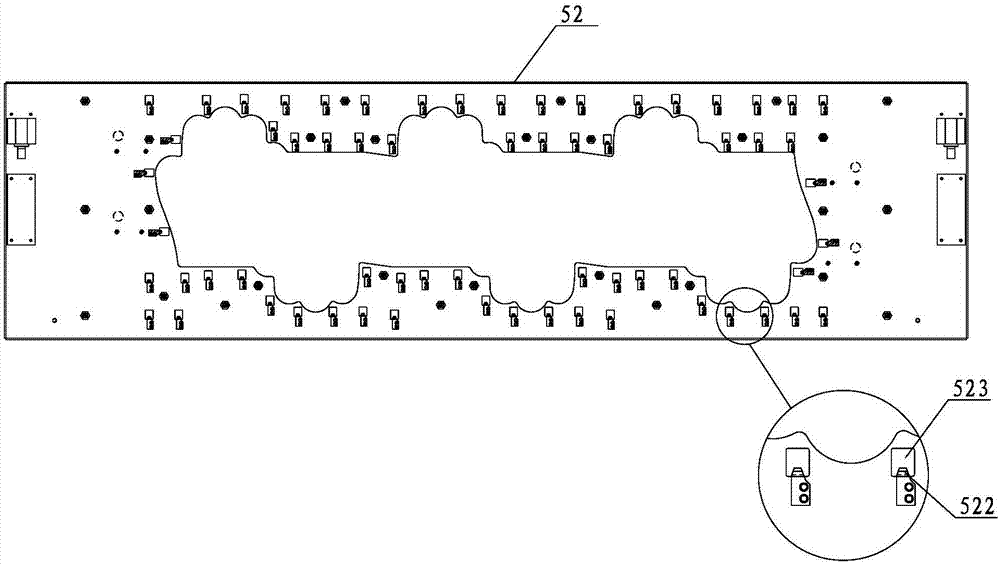

[0024] Such as Figure 2-5 As shown, the cloth grabbing mechanism 5 described in this embodiment includes a cloth grabbing frame and a first cylinder 51 that drives the cloth grabbing frame to move. The cloth grabbing frame includes a bottom plate 52 and a top plate that is movably installed on the bottom plate 52 53, at least two sliders 54 are arranged between the bottom plate 52 and the top plate 53. The base plate 52 is connected with the first cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com