A Laser Arc Hybrid Welding Method for Amorphous Alloy

A technology of amorphous alloy and laser arc, applied in laser welding equipment, welding equipment, welding/welding/cutting items, etc. Production and other issues, to achieve the effect of small thermal deformation, maintain metal structure and mechanical properties, and facilitate welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] In this embodiment, the welding base material is a zirconium-based amorphous alloy Zr-Cu-Ni-Al-Nb, and the welding workpiece 1 is a zirconium workpiece, wherein the welding workpiece 1 in this embodiment is a zirconium bolt.

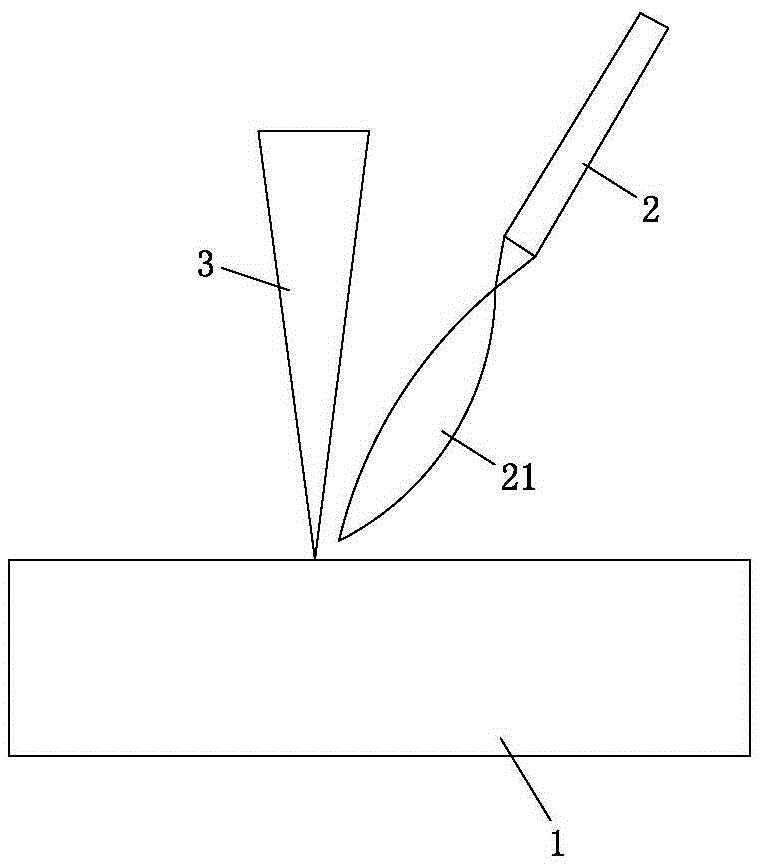

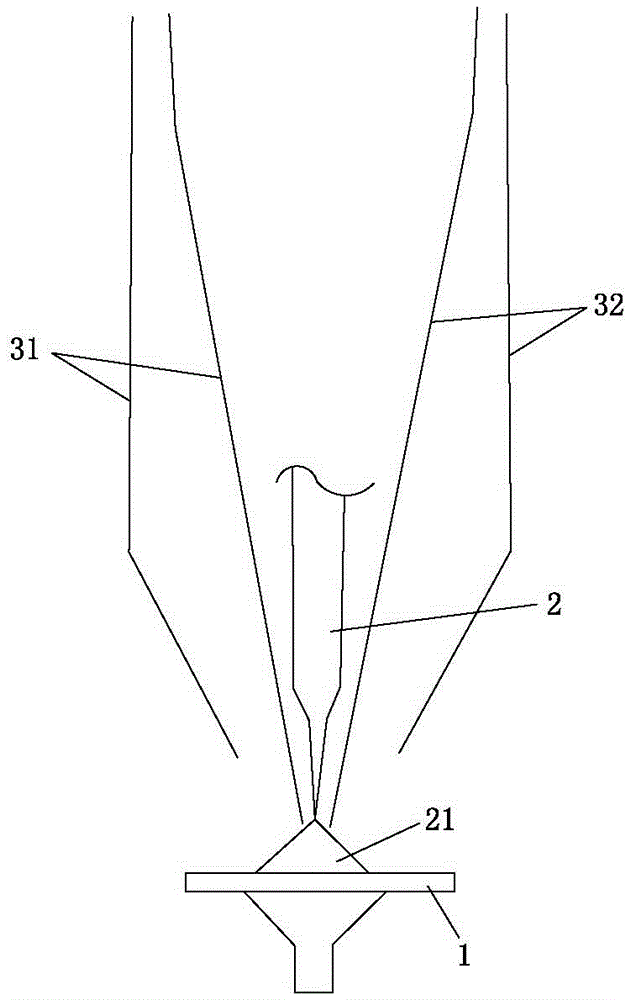

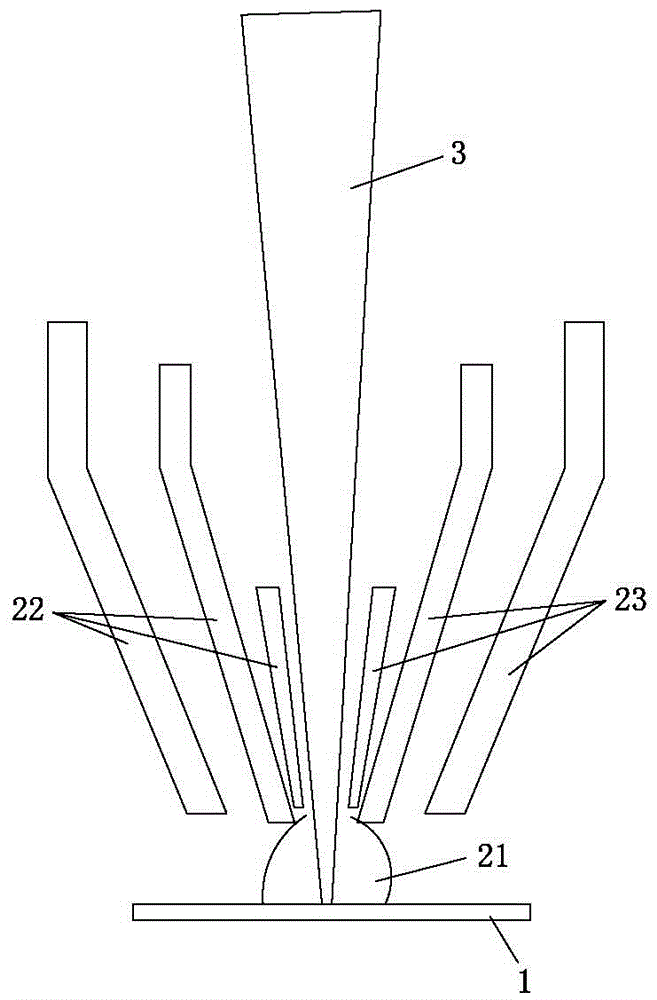

[0045] See figure 1 . A laser arc hybrid welding method for an amorphous alloy in this embodiment, the welding method is that the electrode 2 and the laser beam 3 are arranged in a paraxial composite manner, that is, the electrode 2 and the laser beam 3 are arranged on different axes, and the electrode 2 and the laser beam 3 are arranged on different axes. The bundles 3 form an acute angle between them. In this embodiment, the angle between the electrode 2 and the laser beam 3 is 30 degrees. Wherein, in this embodiment, the electrode 2 is a hollow tungsten electrode. The arc 21 generated by the electrode 2 in this embodiment is a MIG arc.

Embodiment 2

[0047] In this embodiment, the welding base material is a zirconium-based amorphous alloy Zr-Cu-Ni-Al-Nb, and the welding workpiece 1 is a copper workpiece, wherein the welding workpiece 1 in this embodiment is a copper nut.

[0048] See figure 1 . A laser arc hybrid welding method for an amorphous alloy in this embodiment, the welding method is that the electrode 2 and the laser beam 3 are arranged in a paraxial composite manner, that is, the electrode 2 and the laser beam 3 are arranged on different axes, and the electrode 2 and the laser beam 3 are arranged on different axes. The bundles 3 form an acute angle between them. In this embodiment, the angle between the electrode 2 and the laser beam 3 is 45 degrees. Wherein, the arc 21 generated by the electrode 2 in this embodiment is a TIG arc.

Embodiment 3

[0050] In this embodiment, the welding base material is a zirconium-based amorphous alloy Zr-Cu-Ni-Al-Nb, and the welding workpiece 1 is a nickel workpiece.

[0051] See figure 1 . A laser arc hybrid welding method for an amorphous alloy in this embodiment, the welding method is that the electrode 2 and the laser beam 3 are arranged in a paraxial composite manner, that is, the electrode 2 and the laser beam 3 are arranged on different axes, and the electrode 2 and the laser beam 3 are arranged on different axes. The bundles 3 form an acute angle between them. In this embodiment, the angle between the electrode 2 and the laser beam 3 is 40 degrees. Wherein, the arc 21 generated by the electrode 2 in this embodiment is a plasma arc.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com