A kind of welding method of amorphous alloy and nut

A technology of amorphous alloys and welding methods, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems that it is difficult to realize the structure of bolts and nuts, the connection strength cannot meet the production, and the connection strength cannot meet the requirements, so as to achieve joint The effect of high force, good bonding force and good tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

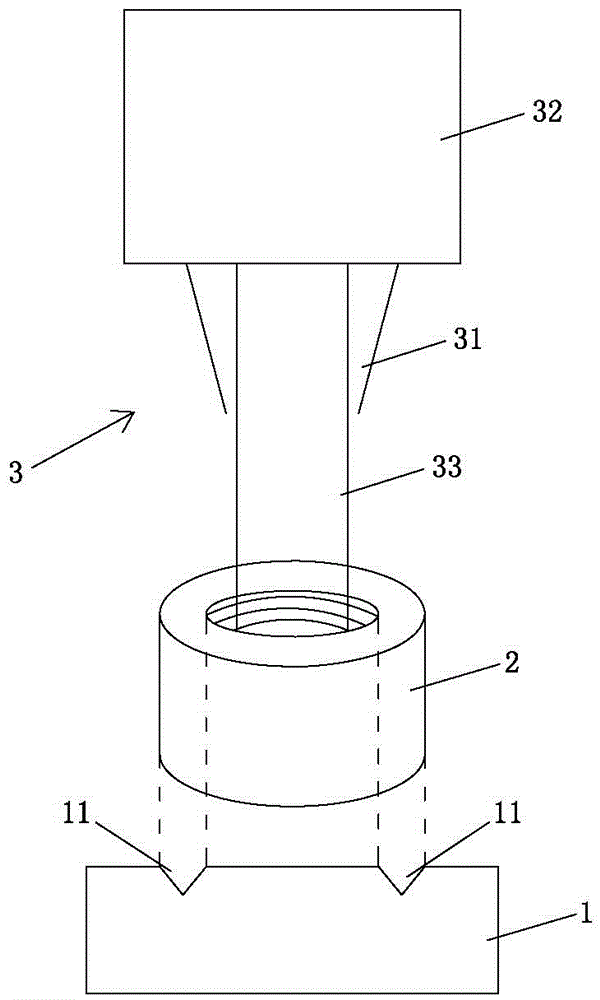

[0041] See figure 1 . A welding method for an amorphous alloy and a nut, comprising an amorphous alloy base material 1 and a nut 2, the amorphous alloy base material 1 used in this embodiment is a Zr-Cu-Ni-Al-Nb alloy, and the used nut 2 The material is carbon steel.

[0042] The rotating device 3 is used to drive the nut 2 to rotate and press against the amorphous alloy substrate 1 at a rotational speed of 2200rpm and a feed rate of 15mm / min, and make the nut 2 rub against the amorphous alloy substrate 1 to generate heat, so that the amorphous The alloy substrate 1 reaches the supercooled liquid phase region above the Tg temperature and below the Tx temperature or reaches above the Tm temperature, the amorphous alloy substrate 1 enters a viscous or molten state, and then under the protection of helium, the amorphous alloy substrate 1 engage with nut 2;

[0043] In this embodiment, the amorphous alloy base material 1 is provided with two grooves 11 for welding with the nut ...

Embodiment 2

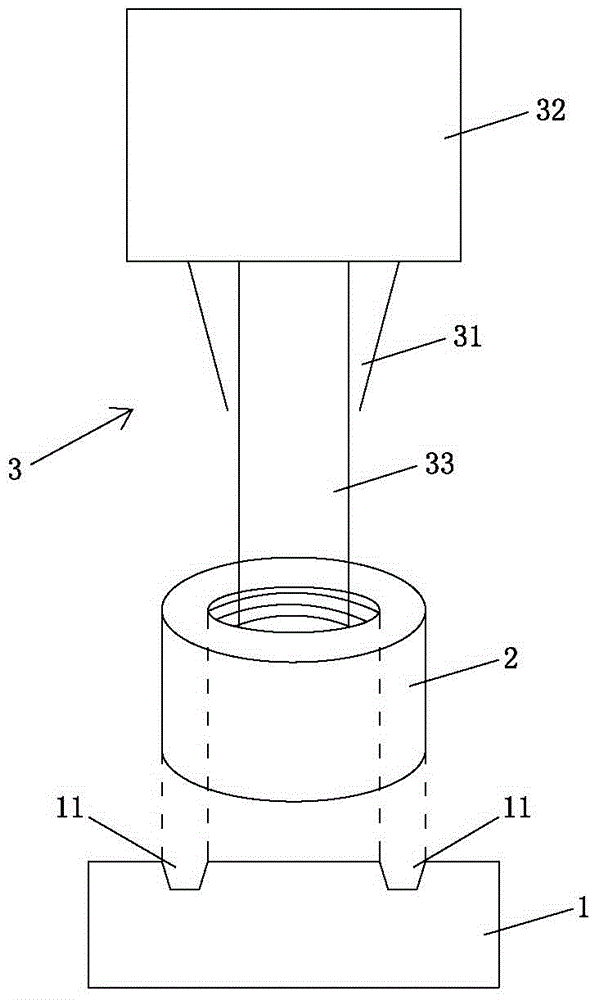

[0048] See figure 1 . A welding method for an amorphous alloy and a nut, comprising an amorphous alloy base material 1 and a nut 2, the amorphous alloy base material 1 used in this embodiment is a Zr-Cu-Ni-Al-Nb alloy, and the used nut 2 The material is stainless steel.

[0049]Rotating device 3 is used to drive nut 2 to rotate and press against amorphous alloy substrate 1 with a rotation speed of 2000rpm and a feed rate of 20mm / min, and make nut 2 rub against amorphous alloy substrate 1 to generate heat, so that the amorphous alloy The alloy substrate 1 reaches the supercooled liquid phase region above the Tg temperature and below the Tx temperature or reaches above the Tm temperature, the amorphous alloy substrate 1 enters a viscous or molten state, and then under the protection of neon gas, the amorphous alloy substrate 1 engage with nut 2;

[0050] In this embodiment, the amorphous alloy base material 1 is provided with two grooves 11 for welding with the nut 2, and the...

Embodiment 3

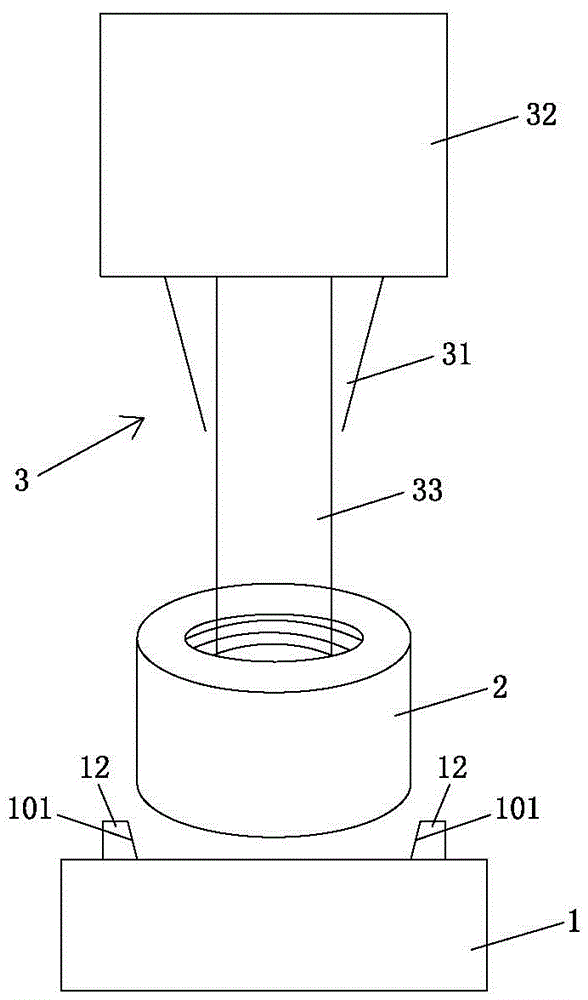

[0055] See figure 1 . A welding method for an amorphous alloy and a nut, comprising an amorphous alloy base material 1 and a nut 2, the amorphous alloy base material 1 used in this embodiment is a Zr-Cu-Ni-Al-Nb alloy, and the used nut 2 The material is copper.

[0056] The rotating device 3 is used to drive the nut 2 to rotate and press against the amorphous alloy substrate 1 at a rotational speed of 1800rpm and a feed rate of 18mm / min, and make the nut 2 rub against the amorphous alloy substrate 1 to generate heat, so that the amorphous alloy The alloy substrate 1 reaches the supercooled liquid phase region above the Tg temperature and below the Tx temperature or reaches above the Tm temperature, the amorphous alloy substrate 1 enters a viscous or molten state, and then under the protection of argon, the amorphous alloy substrate 1 engage with nut 2;

[0057] In this embodiment, the amorphous alloy base material 1 is provided with two grooves 11 for welding with the nut 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com