A double-layer two-phase reactive linear precision adjustment slide table

A precision adjustment and response technology, which is applied in the field of double-layer two-phase reaction linear precision adjustment slide table, achieves the effect of compact shape, simple control method and improved space utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

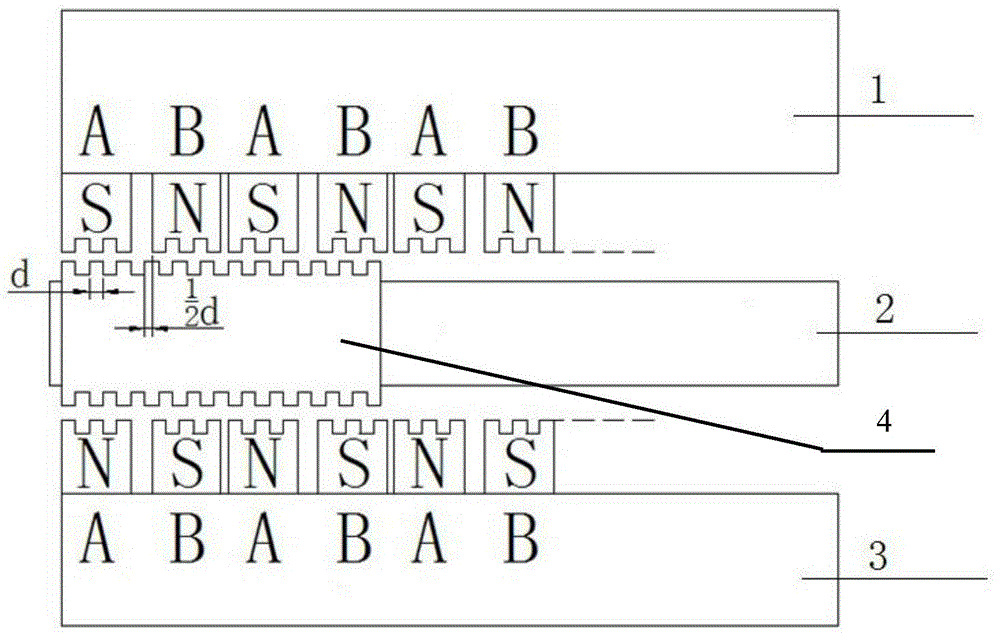

[0017] A double-layer dual-phase reactive linear precision adjustment slide table, including: a reverse-phase fixed plate 1, a linear slide rail 2, a normal-phase fixed plate 3 and a moving plate 4; the reverse-phase fixed plate 1 and the normal-phase fixed plate 3 are silicon steel sheets The tooth-shaped plate is made, and is wound by several coils respectively, and the coils include: A-phase coil and B-phase coil, and the corresponding N pole and S pole of the same-phase coil on the anti-phase fixed plate 1 and the normal-phase fixed plate 3 The polarity is opposite, the teeth of the in-phase coils are aligned, and the distance between any coil and its adjacent coil is 3 / 2 tooth pitch and 1 / 2 tooth pitch (the tooth pitch is represented by "d" in the drawings); The moving plate 4 is arranged in the middle of the anti-phase fixed plate 1 and the positive-phase fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com