Elevator rolling wheel guide shoe

A technology of roller guide shoes and elevator guide rails, which is applied in elevators, transportation and packaging, etc. It can solve problems such as the gap between the rollers and the guide rails, the installation of the rollers and the guide rails is too tight, and the rollers cannot rotate normally, so as to achieve small wear and smooth elevator operation. Smooth, vibration- and noise-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, wherein the schematic embodiments and descriptions are only used to explain the present invention, but are not intended to limit the present invention.

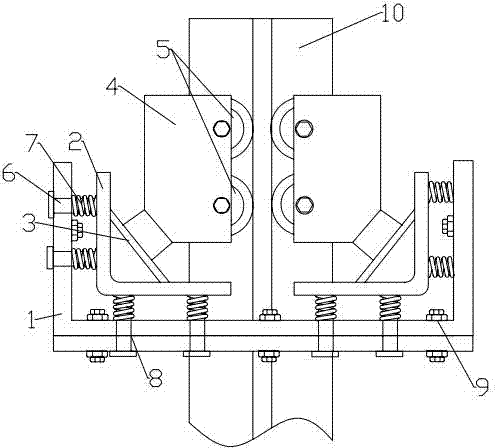

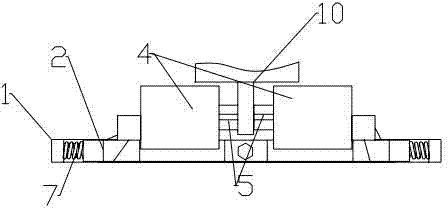

[0017] Such as figure 1 The elevator roller guide shoe shown is installed on the elevator guide rail 10, and includes a shoe seat 1 connected to the elevator car, and a pair of buffer rollers 5 devices symmetrically installed on the shoe seat 1; the buffer roller 5 device It includes an L-shaped bracket 2, a support plate 3, a wheel base 4, and a roller 5; the support plate 3 is fixed on the inner side of the L-shaped bracket 2; the wheel base 4 is fixed on the support plate 3; the roller 5 Installed on the wheel seat 4; a pair of rollers 5 on the buffer roller 5 device are symmetrically clamped on the rails on both sides of the elevator guide rail 10 with the guide rail 10 as the axis of sym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com