Pressure Test Method for Blast Furnace Body Cooling Water Pipeline

A technology for cooling water pipes and blast furnaces, which is applied to cooling devices, inspection devices, etc., can solve the problems of labor-consuming, time-consuming, materials, long secondary pressurization, etc., so as to reduce construction costs, save installation materials, and simplify the method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

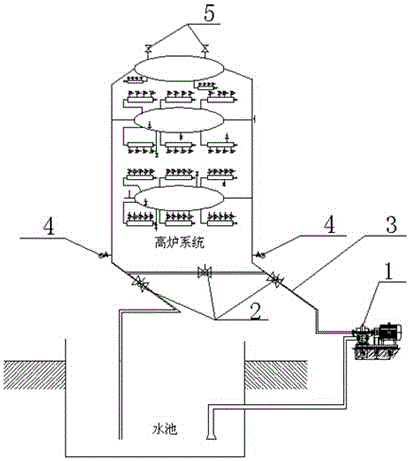

[0012] Referring to the accompanying drawings, the blast furnace body cooling water pipeline pressure test method, its specific technical scheme is:

[0013] 1. Installation of equipment: Install a pipe in the water supply pipe and return water pipe of the blast furnace respectively and set up a quick cut-off ball valve 2 corresponding to the size, and then install a bypass pipe 3 to connect the water supply and return water pipes. Install a quick shut-off ball valve of the corresponding size. The valve core of the quick shut-off ball valve is a metal semi-circular ball with good sealing performance. The opening of the valve is 0°-90°. 0° is a fully closed state, 90° is a fully open state, and a pressure gauge 4 is installed on the water supply and return water pipes to observe the internal water pressure of the pipes, and an exhaust valve 5 is installed at the top of the blast furnace cooling water system. It is responsible for the exhaust work when the pipeline is filled wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com