Stay cable with porous hollow housing for cable stayed bridge

A cable-stayed bridge and cable-stayed technology, applied in the field of stay cables, can solve problems such as increasing the galloping vibration of the dry cable, and achieve the effects of reducing static wind load, avoiding wind-rain-induced vibration, and restraining wind-rain-induced vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

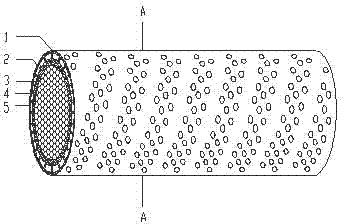

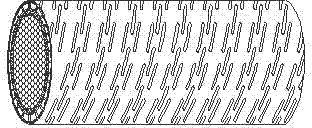

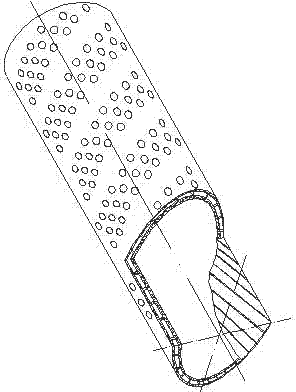

[0022] like Figure 1 to Figure 4 As shown, a cable-stayed cable-stayed bridge with a perforated hollow cover is composed of a high-strength galvanized steel wire 2, a surface sheath 3, a spiral rib 4 and a perforated cover 5 from the inside to the outside; The high-strength galvanized steel wire 2 is fixed in the surface sheath 3. The surface sheath 3 and the perforated cover 5 are concentric circular tubes. There is a certain gap between the perforated cover 5 and the surface sheath 3. The gap space At least one helical rib 4 coaxial with the circular pipe is arranged inside, and the inner and outer helical edges of the helical rib 4 are respectively consolidated with the pipe wall of the surface sheath 3 and the perforated outer cover 5 .

[0023] The rotation direction of the helical ribs 4 is left helical or right helical, the number o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com