Formwork for concrete structure pouring and pouring construction method

A construction method and concrete technology, applied in the direction of formwork/formwork/work frame, connection parts of formwork/formwork/work frame, building structure, etc., to achieve the effect of long turnover period, reducing human damage and saving construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

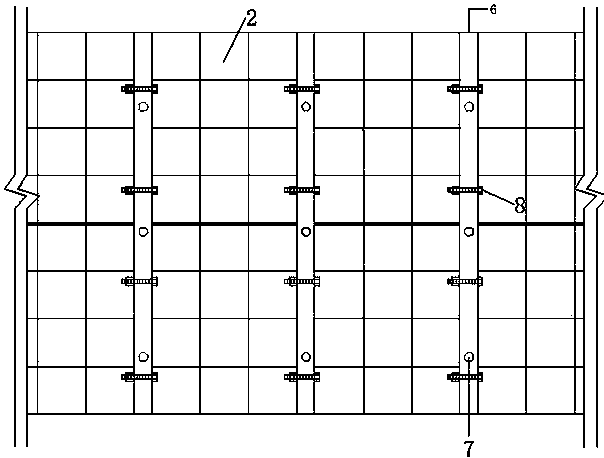

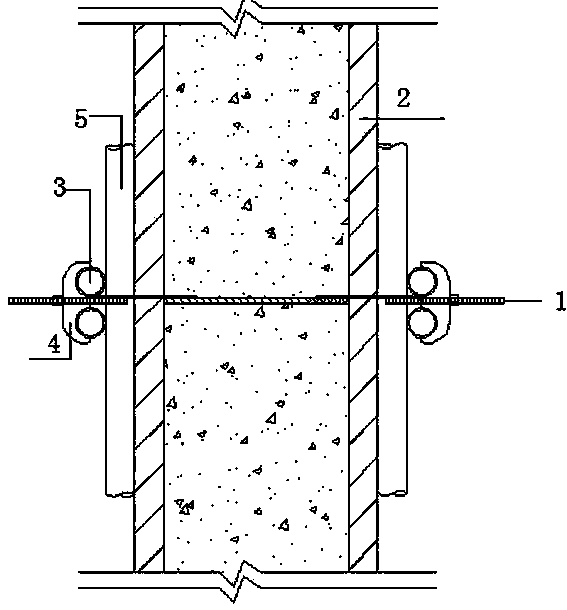

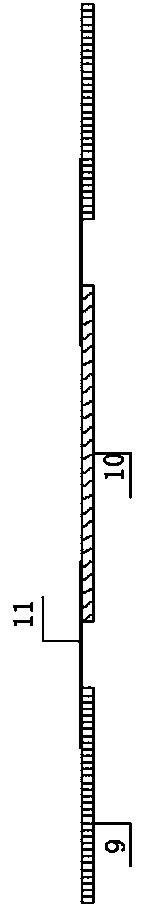

[0035] Such as Figure 1 to Figure 4 As shown, a formwork for pouring concrete structures includes two side forms, a tie mechanism 1 for tying the knot between the two side forms, and a vertical keel 5 and a transverse keel 3 placed outside each side formwork. Between the two side formworks is the concrete pouring area. Each side formwork comprises steel formwork 2 and square wood 6. The square wood has embedded parts piercing holes 7 and bolt holes 8 that both go through the square wood. The bolt holes are vertically arranged with the embedded parts piercing holes. The bolt holes correspond to the bolt holes on the two steel formworks adjacent to the wooden square. It is connected with two adjacent steel formworks by bolts. The tie mechanism includes a tie rod, a nut and a chevron 4. The tie rod includes a threaded section 9, a flat section 11, a steel bar section 10, a flat section and a threaded section connected in sequence. The length of the steel bar section is equal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com