A type k344 packer with two-stage packer unit

A packer and sealing ring technology, which is applied in sealing/isolation, wellbore/well parts, earthwork drilling and production, etc., can solve problems such as high development cost, interruption of fracturing construction, and influence on fracturing construction effect, and achieve Effect of prolonging service life and overcoming high development cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

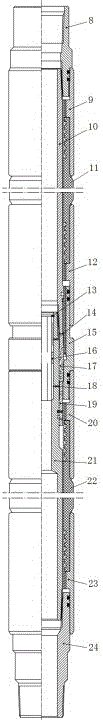

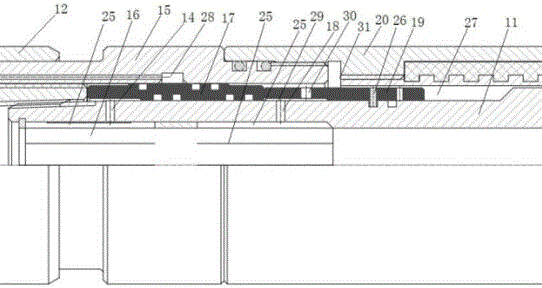

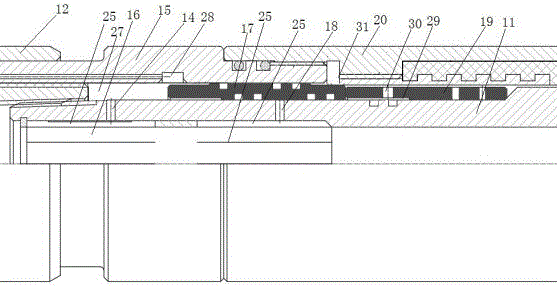

[0021] like figure 1 The K344 type packer with dual-stage packer unit shown includes the first-stage K344-type packer unit and the second-stage K344-type packer unit, and the two packer units are of the same structure. The prior art will only be briefly described below. In the present invention, the first stage K344 type packer unit and the second stage K344 type packer unit are fixedly connected through the middle joint 15; The type packer unit is located above the mid-joint 15. The first-stage K344 packer unit mainly includes the lower joint 24 of the first-stage K344-type packer unit, the glue cylinder seat 20 of the first-stage K344-type packer unit, and the first-stage K344-type packer unit. The lower rubber barrel seat 23, the first-stage K344 packer unit rubber barrel 22 and the lower central pipe 21 and other components. The second-stage K344 packer unit mainly includes the upper joint 8 of the second-stage K344-type packer unit, the glue cylinder seat 9 of the sec...

Embodiment 2

[0023] On the basis of Example 1, the first-stage K344-type packer unit and the second-stage K344-type packer unit are respectively connected with the middle joint 15 by screws. The specific connection is as follows: the upper rubber barrel seat 20 of the first-stage K344 packer unit is threadedly connected to the lower end of the middle joint 15, and the lower rubber barrel seat 12 of the second-stage K344 type packer unit is connected with the upper end of the middle joint 15. threaded connection. In this embodiment, the lower central pipe 21 is sleeved with a sand control pipe 16 at the upper pressure guide water hole 14 and the lower pressure guide water hole 18 to prevent sand from entering the rubber cylinder of the packer. The sand control tube 16 is fixed by the circlip 13, which is a standard part and is fixed in the inner wall groove of the lower center tube 21. The method of fixing by the circlip 13 is the prior art in the art, and will not be described in detail he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com