Improved one-way overrunning clutch

A one-way overrunning and clutch technology, which is applied to one-way clutches, clutches, mechanical equipment, etc., can solve the problems of easily damaged springs and no better solutions, and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

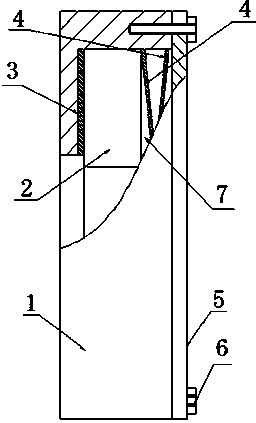

[0009] to combine figure 1 , the specific embodiment of the present invention is:

[0010] The improved one-way overrunning clutch is composed of housing (1), one-way overrunning clutch (2), friction plate (3), butterfly spring (4), end cover (5), bolt ( 6) Composed of, the feature is: the casing (1) is made with a stepped hole (7), and the friction plate (3) is fixed on the inner end surface of the stepped hole (7), and the one-way overrunning clutch (2) Set in the stepped hole (7) of the housing (1), wherein there is a small gap between the outer circle of the one-way overrunning clutch (2) and the inner circle of the stepped hole (7), and the inner end surface of the one-way overrunning clutch (2) In close contact with the friction plate (3), set several butterfly springs (4) at the mouth of the stepped hole (7), and fix a bolt (6) at the mouth of the stepped hole (7) on the end surface of the housing (1) The end cover (5), the end cover (5) presses the one-way over...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com