Reversed bending preventing transmission chain

A transmission chain and anti-reverse technology, applied in the direction of transmission chains, chain links, etc., can solve problems such as instability and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

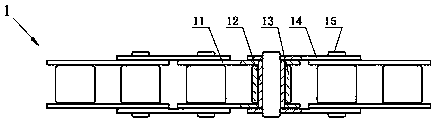

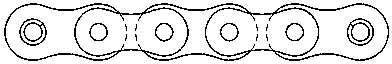

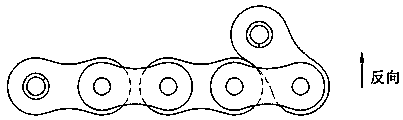

[0031] attached Figure 5-12 It is an anti-reverse bending transmission chain according to the present invention, which includes a left bending plate 21, a sleeve 22, a roller 23, a right bending plate 24, and a pin shaft 25; the left bending plate 21 and the right bending plate 24 are respectively It is in the shape of a horizontally stretched Z, and two parallel flat plates are connected together by the connecting plate 216, and the two parallel flat plates have the same width; the two vertical flat plates on the left curved plate 21 The one near the outside is the first flat plate, and the one near the inside is the second flat board. The center of the first flat board is provided with a first small hole 214, and the center of the second flat board is provided with a first large hole 215; Among the two vertical flat plates on the plate 24, the one close to the outside is the third flat plate, and the one close to the inside is the fourth flat plate. The center of the third ...

no. 2 example

[0038] as attached Figure 13 , 14 As shown, the difference from the left curved plate and the right curved plate in the first embodiment is that the other end of the second flat plate of the left curved plate is set as a third anti-bending portion 213 parallel to the first anti-bending portion 211; The lower end of the third anti-bending portion 213 is provided with a rounded corner centered on the first large hole 215 .

[0039] The other end of the fourth flat plate of the right bending plate is set as a fourth anti-bending portion 245 parallel to the second anti-bending portion 241; the lower end of the fourth anti-bending portion 245 is provided with a second large hole 244 as the center rounded corners.

[0040] When working, the first anti-bending portion 211 and the third anti-bending portion 213 on the left bending plate can prevent reverse bending, and the second anti-bending portion 241 and the fourth anti-bending portion 245 on the right bending plate Both can p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com