Z-shaped steel sheet pile, and steel sheet pile wall formed from said Z-shaped steel sheet pile

A technology for steel sheet piles and joints, which is applied in sheet pile walls, buildings, and foundation structure engineering, etc. It can solve problems such as easy deformation of joints, easy rotation of Z-shaped steel sheet piles, and large joints, so that the weight of the steel will not increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

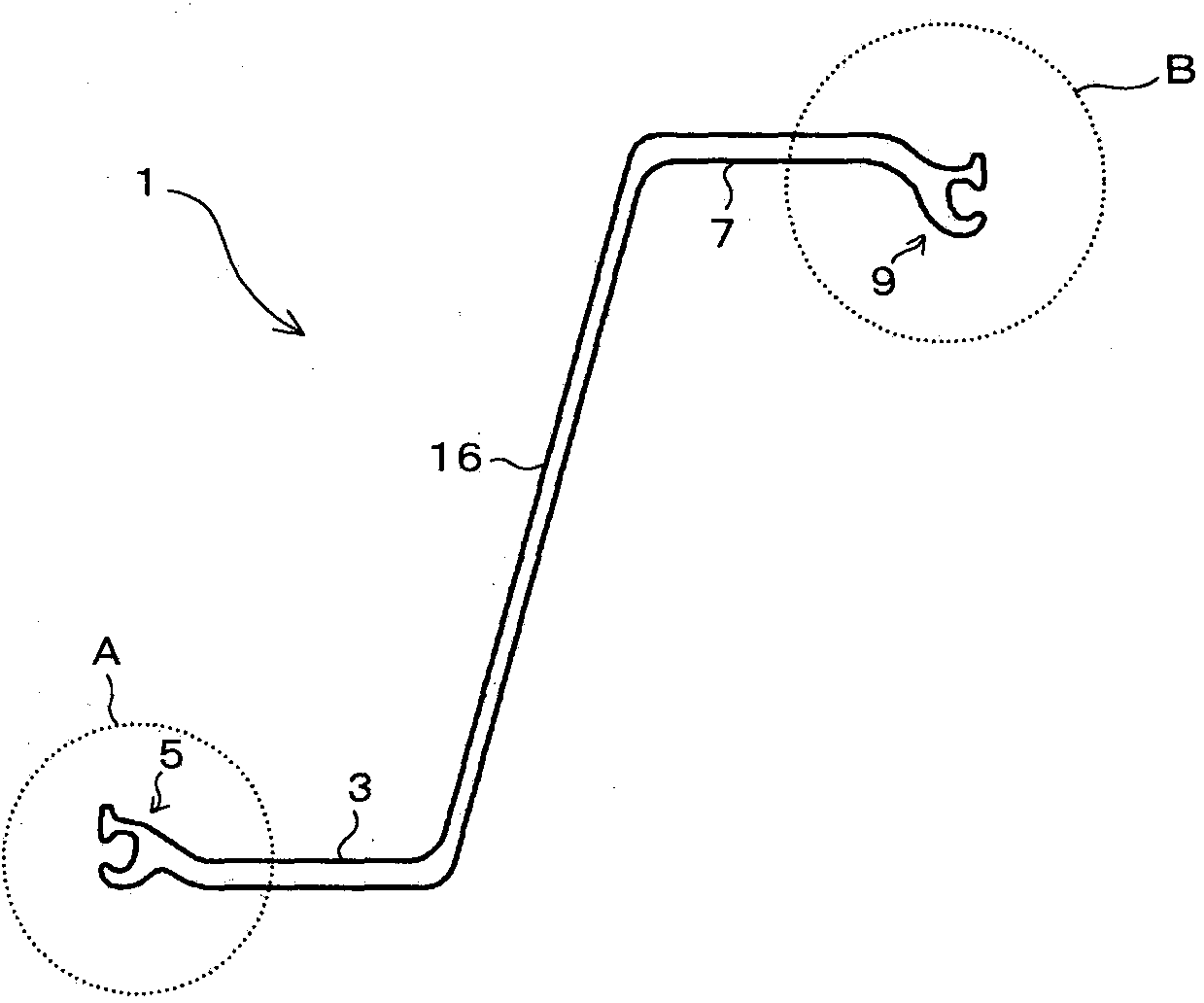

[0043] The Z-shaped steel sheet pile 1 which concerns on this embodiment is a Z-shaped steel sheet pile which has the 1st joint part 5 formed in the terminal end of the 1st flange part 3 which comprises the Z-shaped steel sheet pile 1, and the 2nd joint. The part 9 is formed at the end of the second flange part 7. By arranging the Z-shaped steel sheet piles 1 adjacent to each other and connecting the first joint part 5 and the second joint part 9 in an engaging manner, a steel plate can be formed. Pile wall 27 (refer to Figure 5 ).

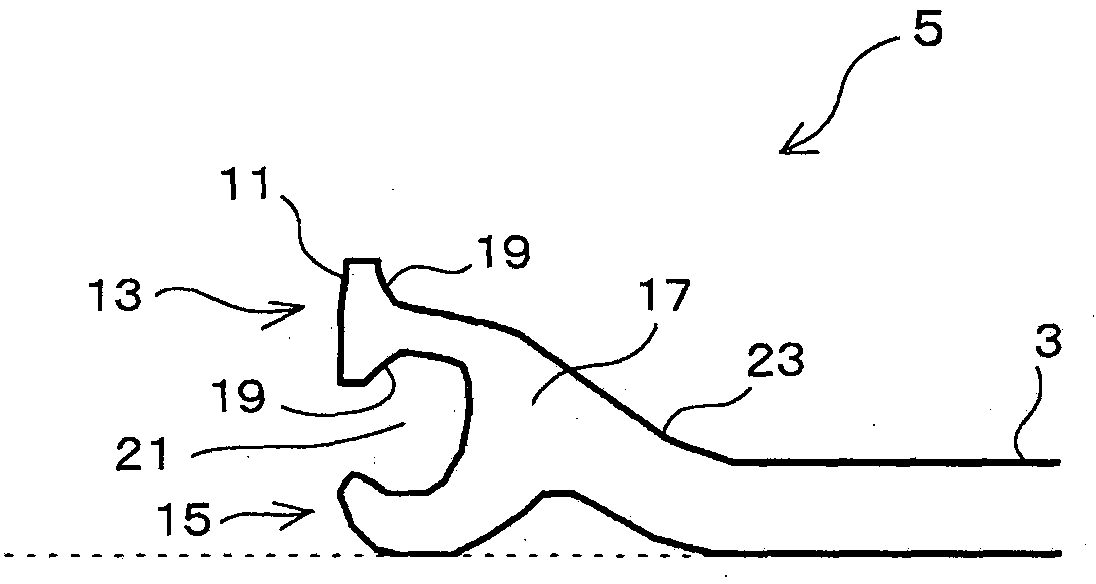

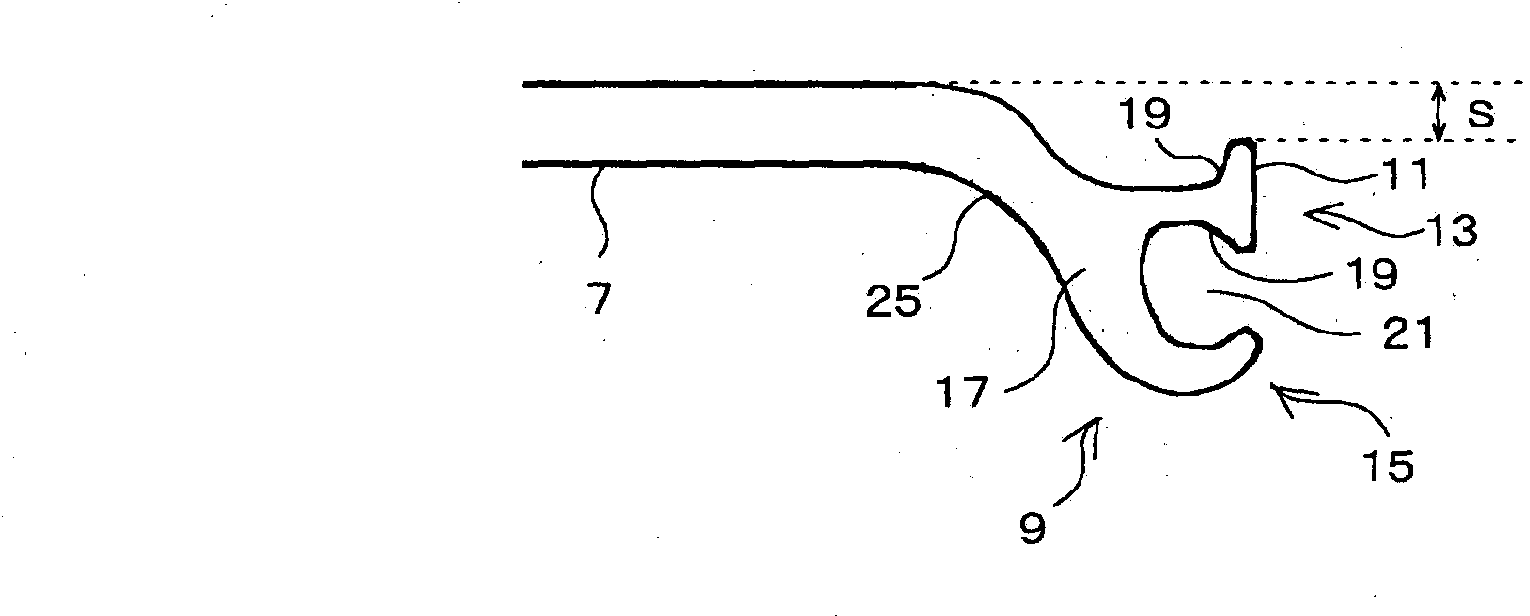

[0044]The first joint part 5 is a double-claw joint part having a main claw 13 and an auxiliary claw 15, wherein the main claw 13 has a bulging part 11 at the end and is arranged inside the steel sheet pile, and the auxiliary claw 15 is connected to the main claw. 13 are formed in an opposing manner and arranged outside the steel sheet piles.

[0045] In addition, the second joint part 9 is a double-claw joint part having a main claw 13 and an ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap