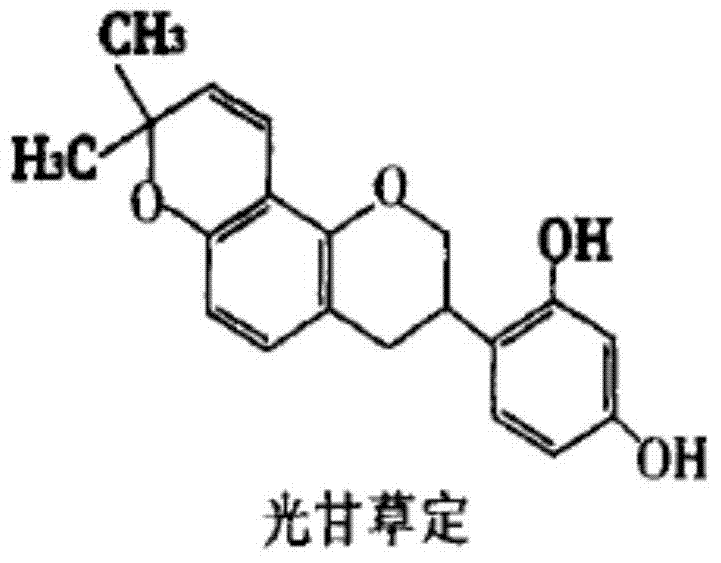

Method for preparing glabridin microcapsules by virtue of complex coacervation-spray drying process

A spray-drying method and glabridin technology, which are applied in pharmaceutical formulations, cosmetic preparations, toiletry preparations, etc., can solve the problem of unsuitable preparation or controlled release of microcapsules, inability to prevent oxygen from entering, and fragile microcapsule wall membranes and other problems, to achieve the effect of simple and feasible preparation process, less cracks, and improved appearance properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Gelatin and gum arabic were heated and dissolved in deionized water to form a 2% mass concentration gelatin solution and a 2% mass concentration gum arabic solution.

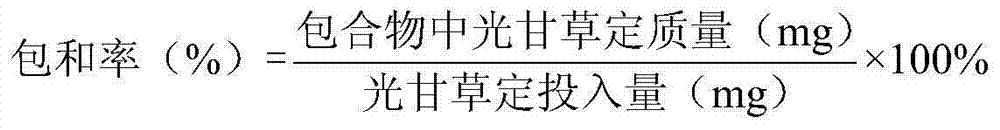

[0044] After mixing the gelatin solution of 2% mass concentration and the gum arabic solution of 2% mass concentration in the ratio of 1:2 by weight to form the gelatin-gum arabic composite wall material solution, the core material glabridin extract and the composite wall material solution According to the weight ratio of 2:1, mix and stir evenly to obtain a mixed solution, then homogenize the mixed solution at a speed of 8000rpm / min, then add 0.5% volume of complex alcohol solubilizer and use acetic acid to adjust the pH of the solution to 4.0. Glycyrrhizin solution 10min obtains emulsion, the formaldehyde that adds 0.5% volume after is emulsification is solidified and obtains glabridin microcapsule solution, and the stirring speed of solidification is 250rpm / min, then glabridin microcapsule solution is a...

Embodiment 2

[0046] Gelatin and gum arabic were heated and dissolved in deionized water to form a 3% mass concentration gelatin solution and a 3% mass concentration gum arabic solution.

[0047] After mixing the gelatin solution of 3% mass concentration and the gum arabic solution of 3% mass concentration in the ratio of 1:2 by weight to form the gelatin-gum arabic composite wall material solution, the core material glabridin extract and the composite wall material solution After mixing and stirring at a weight ratio of 2:1 to obtain a mixed solution, the mixed solution was homogenized at a speed of 12000rpm / min, and then 0.5% volume of complex alcohol solubilizer was added and acetic acid was used to adjust the pH of the solution to 4.0. Glycyrrhizin solution 10min obtains emulsion, the formaldehyde that adds 0.7% volume after is emulsification is solidified and obtains glabridin microcapsule solution, and the stirring speed of solidification is 500rpm / min, then glabridin microcapsule solu...

Embodiment 3

[0049] Gelatin and gum arabic were heated and dissolved in deionized water to form a 5% mass concentration gelatin solution and a 5% mass concentration gum arabic solution.

[0050] After mixing the gelatin solution of 5% mass concentration and the gum arabic solution of 5% mass concentration with a weight ratio of 1:1.5 to form a gelatin-gum arabic composite wall material solution, the core material glabridin extract and the composite wall material solution After mixing and stirring at a weight ratio of 1:1 to obtain a mixed solution, the mixed solution was homogenized at a speed of 8000rpm / min, and then 0.5% volume of complex alcohol solubilizer was added and the pH of the solution was adjusted to 4.0 with acetic acid. Glycyrrhizin solution 20min obtains emulsion, the formaldehyde that adds 0.8% volume after is emulsification is solidified and obtains glabridin microcapsule solution, and the stirring speed of solidification is 750rpm / min, then glabridin microcapsule solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com