LED (light emitting diode) lamp assembling azimuth correction device and LED lamp assembling azimuth correction method

A technology of LED lights and azimuths, which is applied in the direction of lighting devices, workpiece clamping devices, components of lighting devices, etc., can solve the problems of no correction device and detection device, poor stability of electrical connection, etc., and achieve the effect of facilitating automatic assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

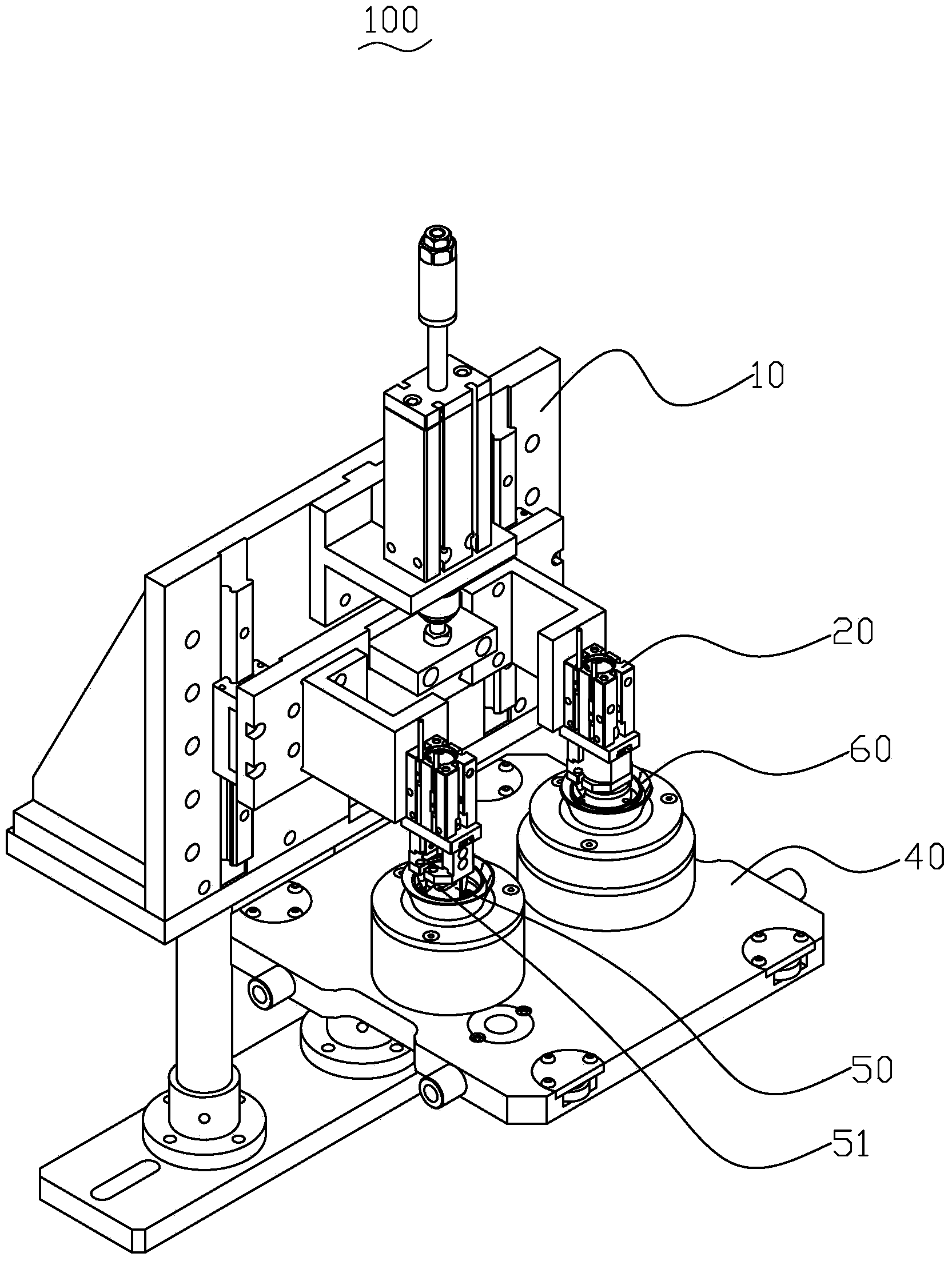

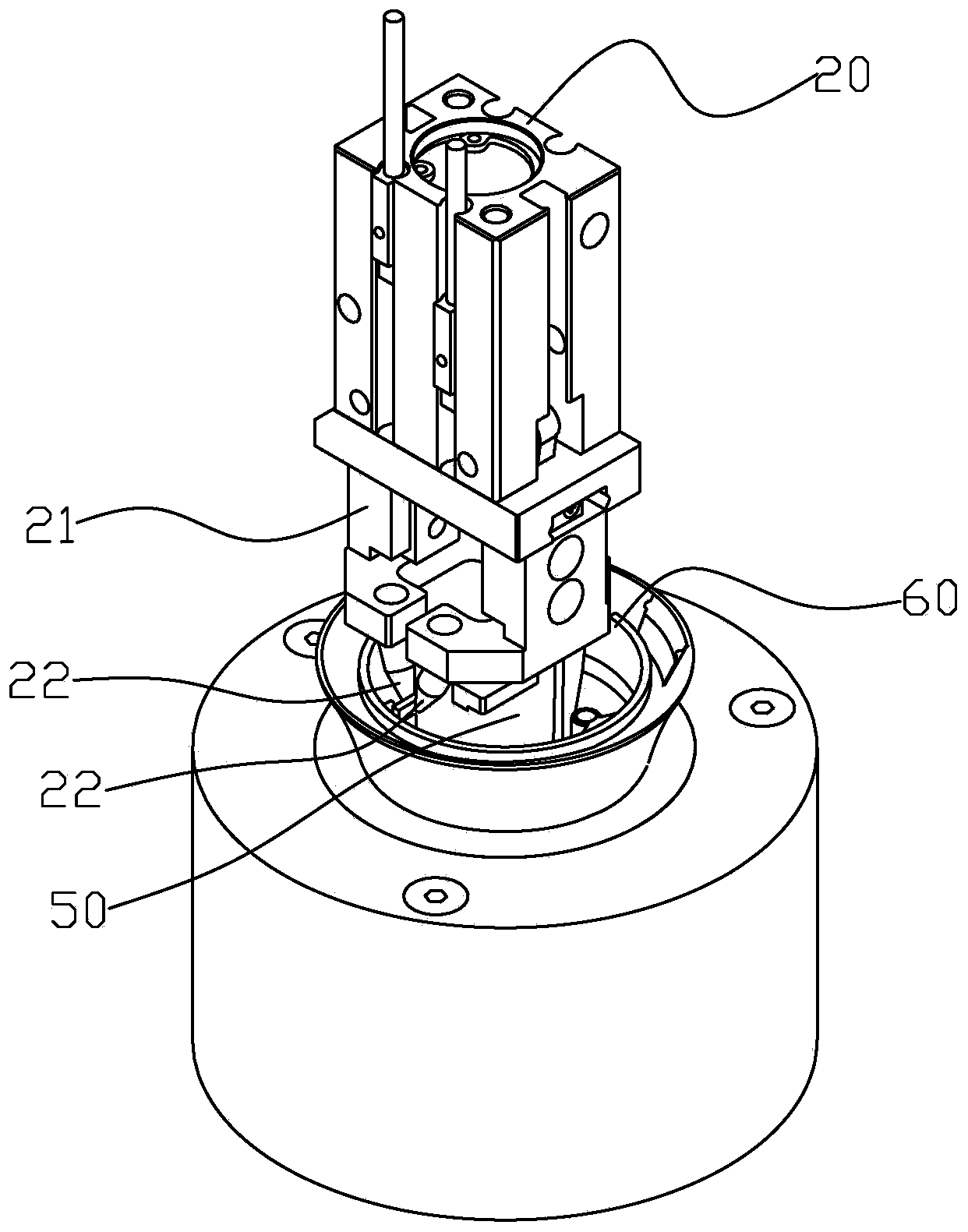

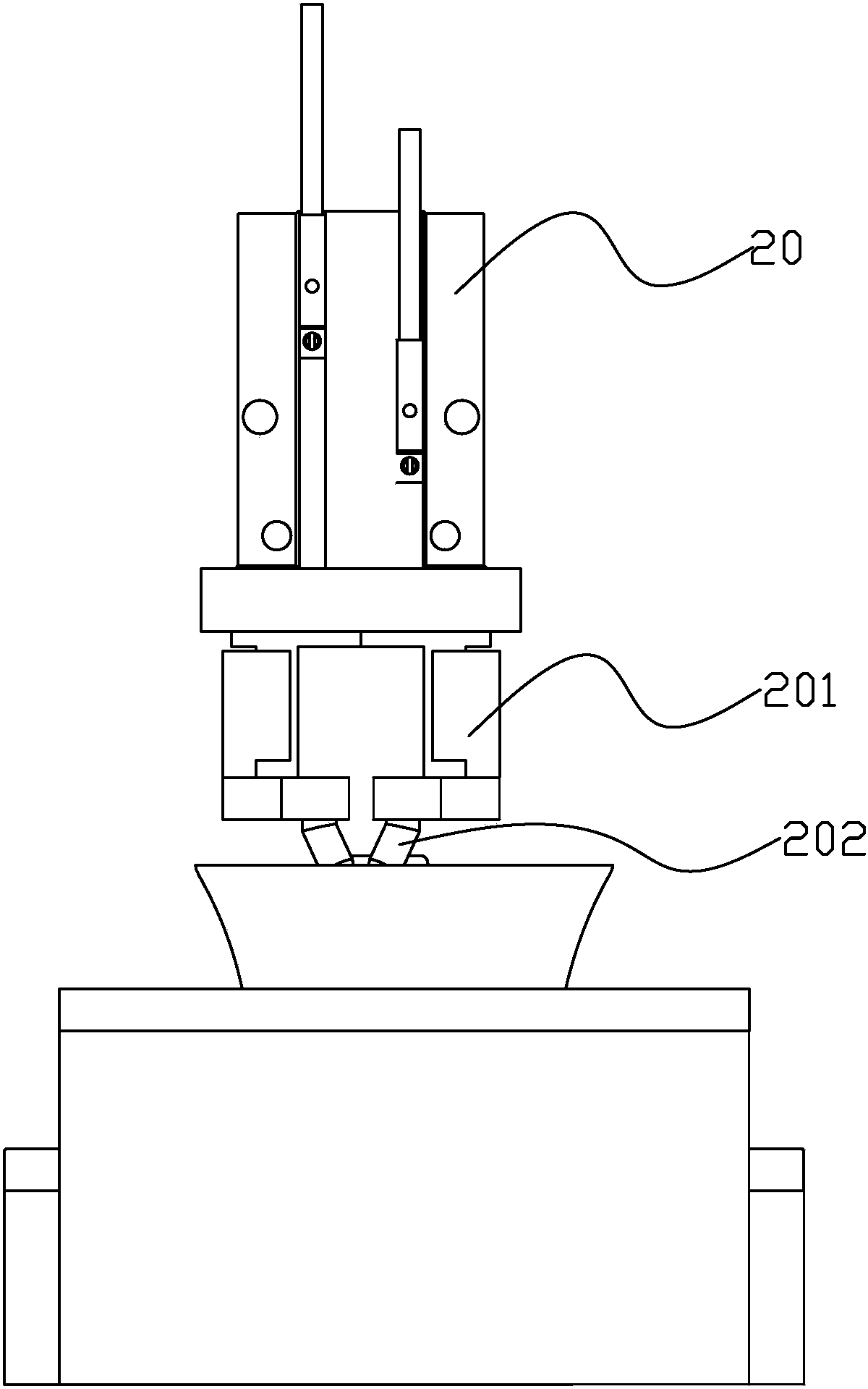

[0016] figure 1 It is a perspective view of an LED lamp assembly orientation correction device 100 according to the first embodiment of the present invention. The LED lamp assembly orientation correction device 100 includes a drive board orientation detection mechanism 10, a drive board orientation correction mechanism 20, and a drive board orientation rotation mechanism (not shown in the figure). ), tooling board 40, driving board 50 and lamp cup 60. The driving plate 50 is assembled in the lamp cup 60 and its position is fixed relative to the lamp cup 60 . When the driving plate 50 is rotated, the lamp cup 60 will also rotate synchronously. One side of the drive board 50 protrudes outwards and is equipped with electronic components 51 (such as Figure 4 shown). The drive board orientation detection mechanism 10 is used to determi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com