A servo motor assembly system and a rear end cap sealing ring assembly device

A technology for assembling devices and servo motors, applied in electromechanical devices, electric components, manufacturing motor generators, etc., can solve problems such as difficult assembly of sealing rings, and achieve the effects of improving the pass rate, reducing production costs, and facilitating automatic assembly

Inactive Publication Date: 2018-12-28

陈荣乾

View PDF2 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to solve the problem of difficult sealing ring assembly, the object of the present invention is to provide a sealing ring assembly device for the rear end cover of the servo motor. When the cover is closed, the actions are coordinated and orderly, which is convenient for the automatic assembly of the sealing ring

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

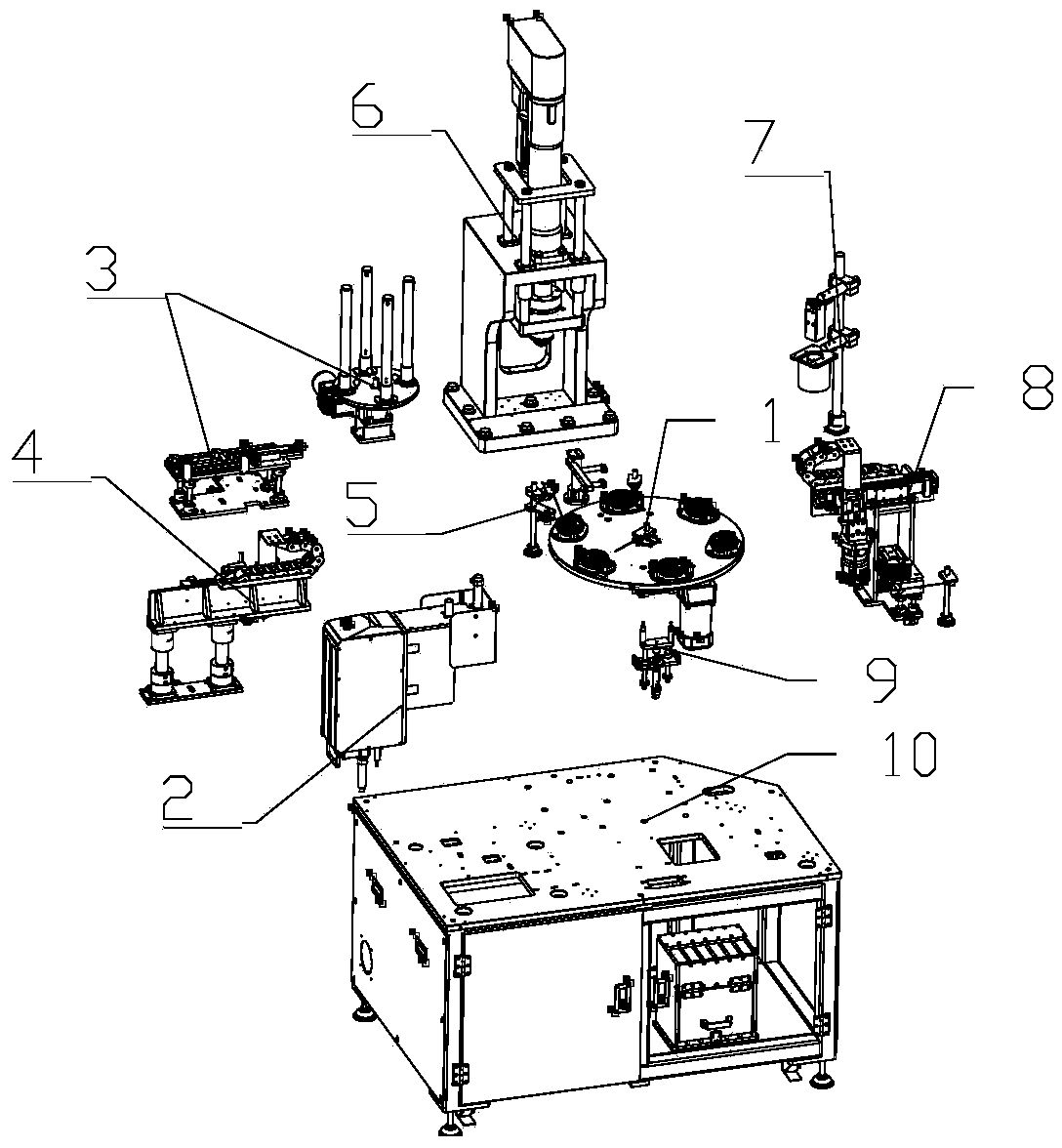

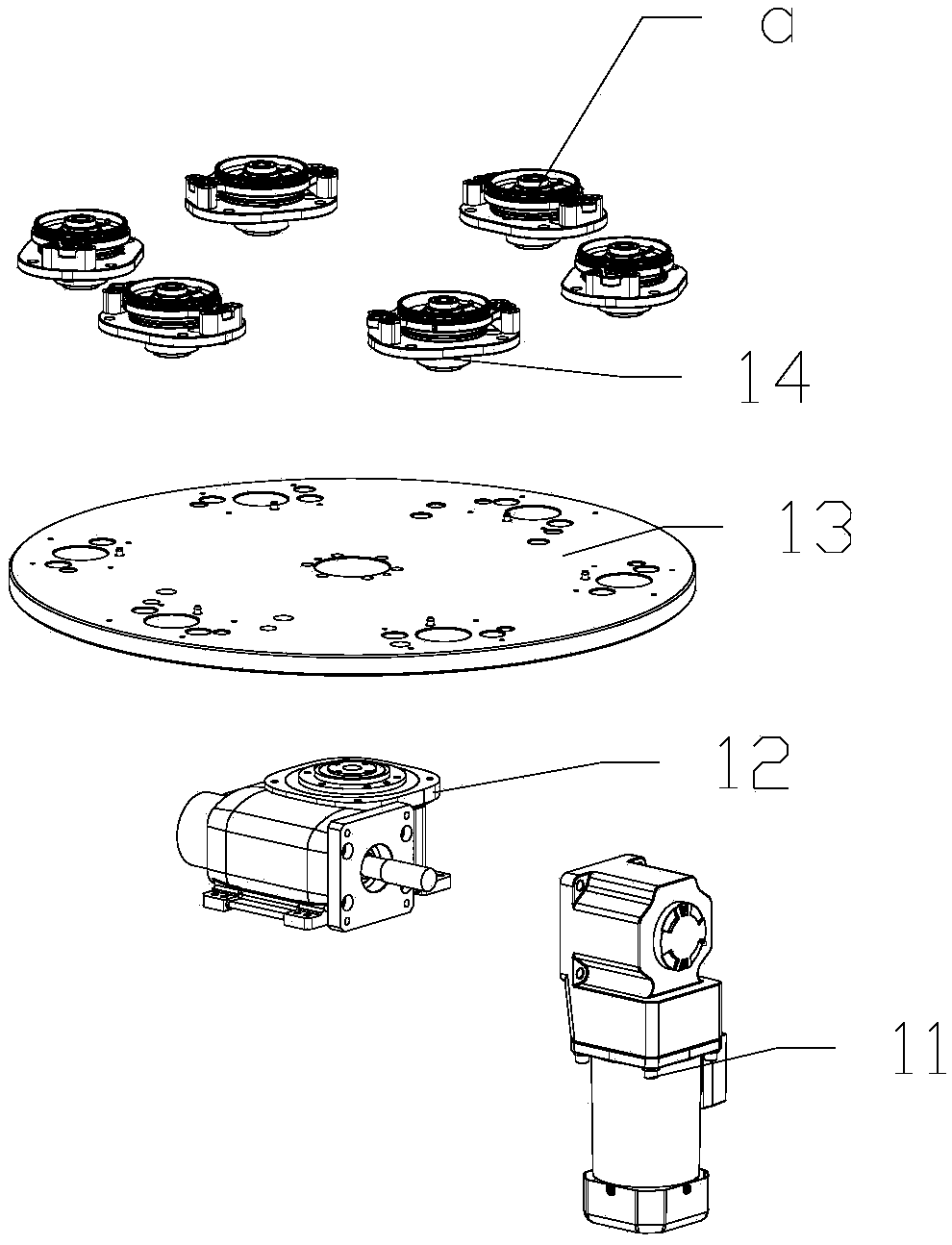

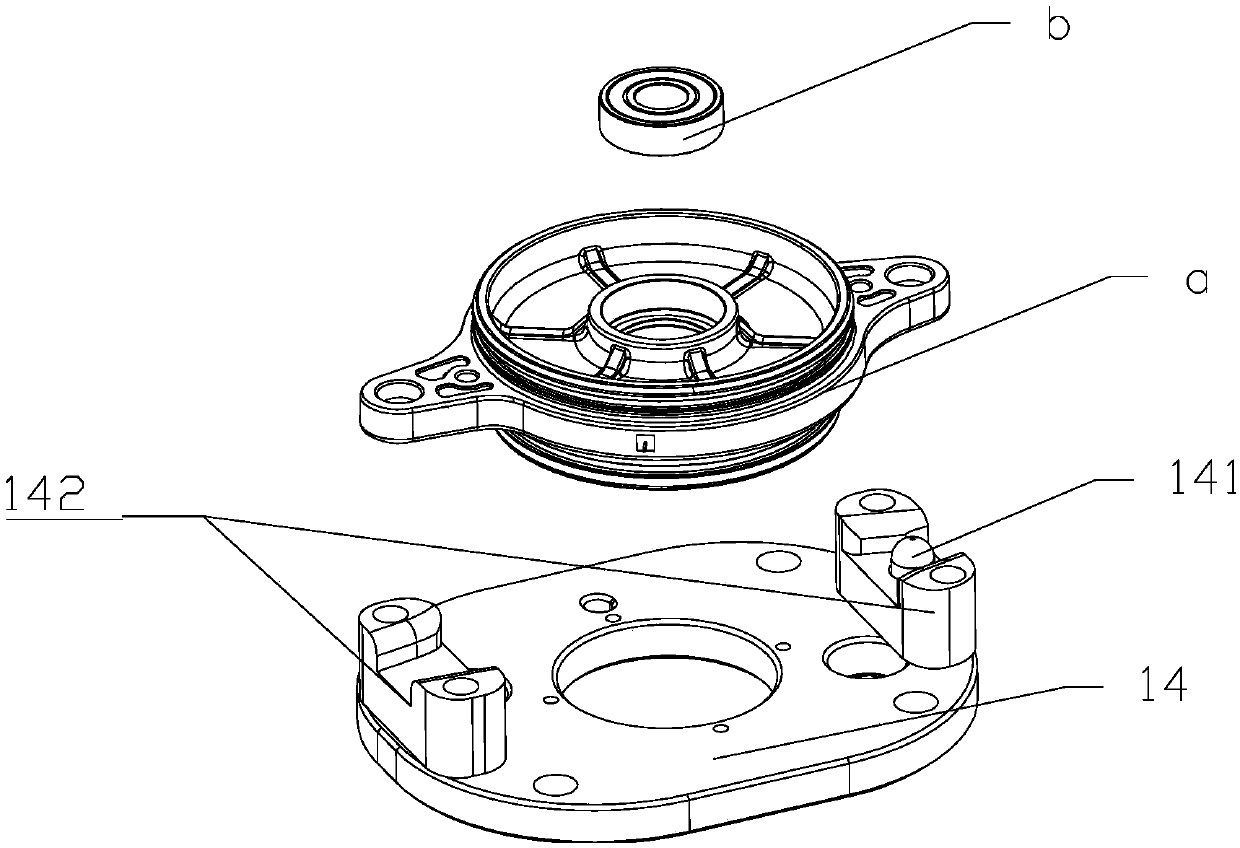

The invention relates to a motor assembly method, in particular to a servo motor assembly system and a rear end cap sealing ring assembly device. The servo motor rear end cap sealing ring assembly device comprises an indexing rotary table device and a sealing ring assembly device. The indexing rotary table device is sequentially provided with a loading and unloading station, a rear end cap detection station, a bearing loading station, a pressing station, a pressing detection station and a sealing ring assembly station. Carriers are respectively arranged on each station, and the sealing ring assembly device corresponds to the sealing ring assembly station. The sealing ring assembling device comprises a fixed bracket, a sixth cylinder placing table, a sealing ring spreading mechanism, a fifth cylinder, a linear moving assembly, a photoelectric sensor assembly, a sixth cylinder, a sealing ring ferrule and a transverse moving guide plate, wherein the sealing ring assembling device comprises a fixed bracket, a sixth cylinder placing table, a sealing ring spreading mechanism, a fifth cylinder, a linear moving assembly, a photoelectric sensor assembly, a sixth cylinder, a sealing ring ferrule and a transverse moving guide plate; the fixing bracket is fixedly arranged on the mounting rack for transversely mounting the linear moving component; the elastic sealing ring is stretched and pushed off, and the device is assembled on the servo motor tail cap by internal stress thereof, and the action is in order, so the automatic assembly of the sealing ring is convenient.

Description

technical field The invention relates to a motor assembly method, in particular to a servo motor assembly system and a rear end cover sealing ring assembly device. Background technique Servo motor (servomotor) refers to the engine that controls the operation of mechanical components in the servo system, and is an auxiliary motor indirect transmission device. The servo motor can control the speed and position accuracy very accurately, and can convert the voltage signal into torque and speed to drive the control object. The servo motor includes a casing, a rotor, an oil baffle and a rear end cover. During production, the above-mentioned components are combined together. The rear end cover of the servo motor is the tail end part of the servo motor. It is necessary to install a bearing to accommodate the rotor, and to install a sealing ring to connect with the main body of the motor. Most of the existing bearings are pressed in manually or by some other equipment. enter. The...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H02K15/14

CPCH02K15/14

Inventor 陈荣乾

Owner 陈荣乾

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com