Nonwoven cementitious composite for in-situ hydration

A composite and non-woven technology, applied in the field of composites, can solve the problems that three-dimensional textiles cannot function independently

Active Publication Date: 2015-01-14

CORTEX COMPOSITES

View PDF11 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Such woven or braided three-dimensional textiles may not functio

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

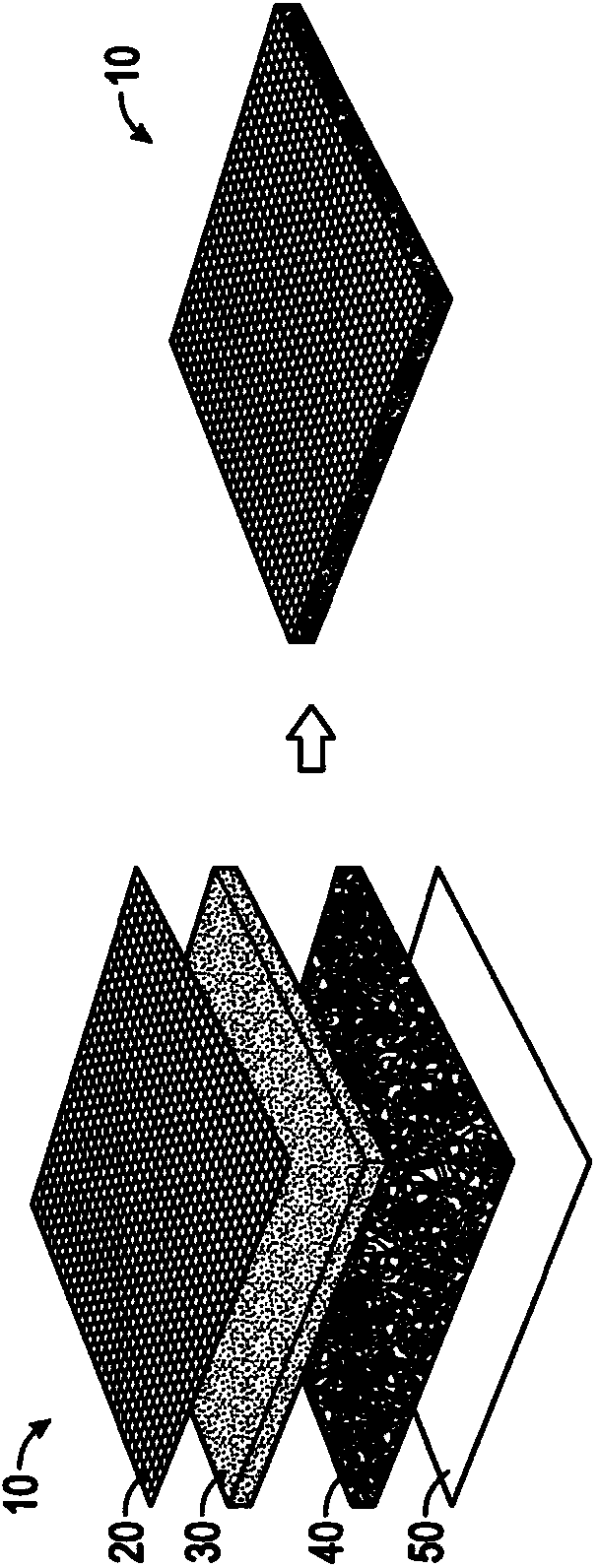

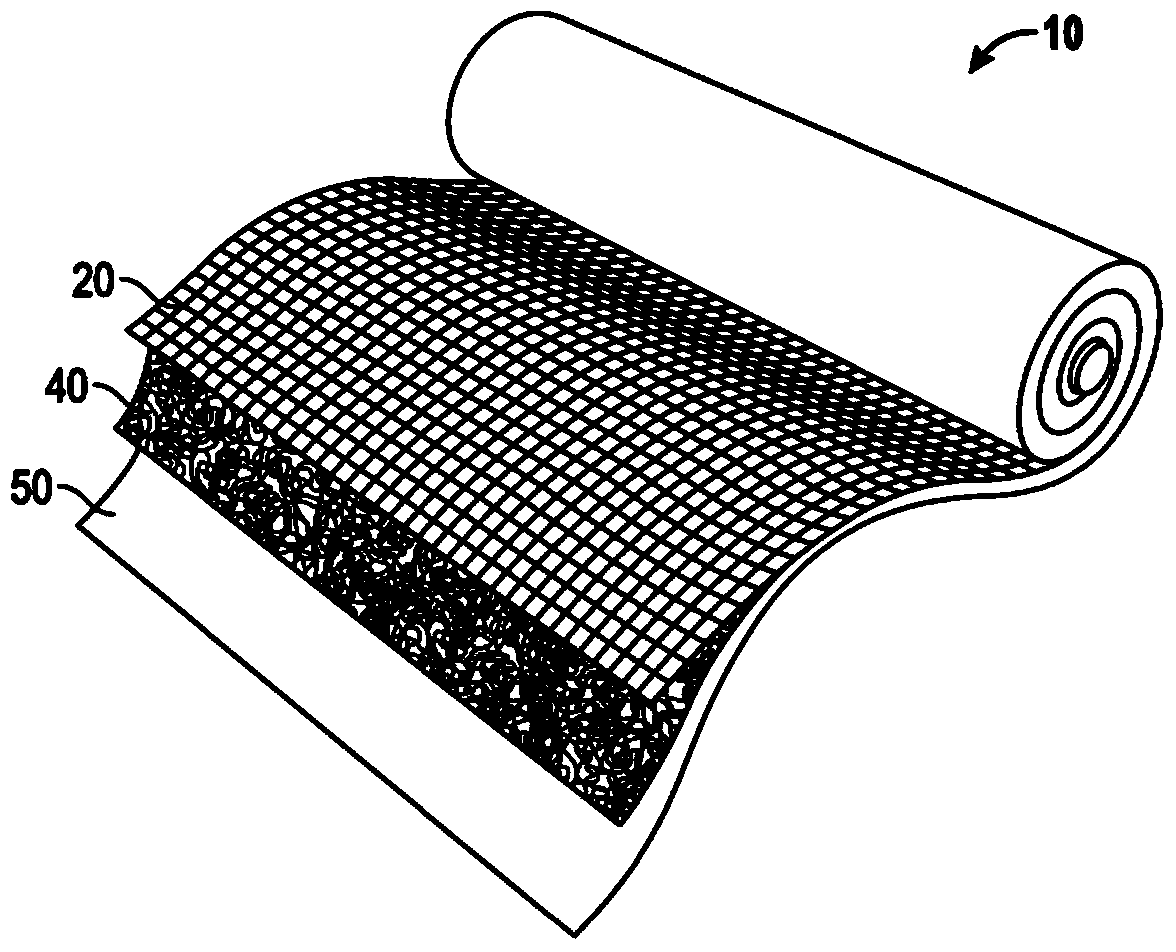

One embodiment of the present disclosure relates to a cementitious composite material for in-situ hydration having a mesh layer including a first side, a second side, and a plurality of fibers arranged in a nonwoven configuration; a cementitious material having a plurality of cementitious particles disposed within the mesh layer; a sealing layer disposed along the first side of the mesh layer and coupled to the plurality of nonwoven fibers; and a containment layer disposed along the second side of the mesh layer and configured to prevent the plurality of cementitious particles from migrating out of the mesh layer.

Description

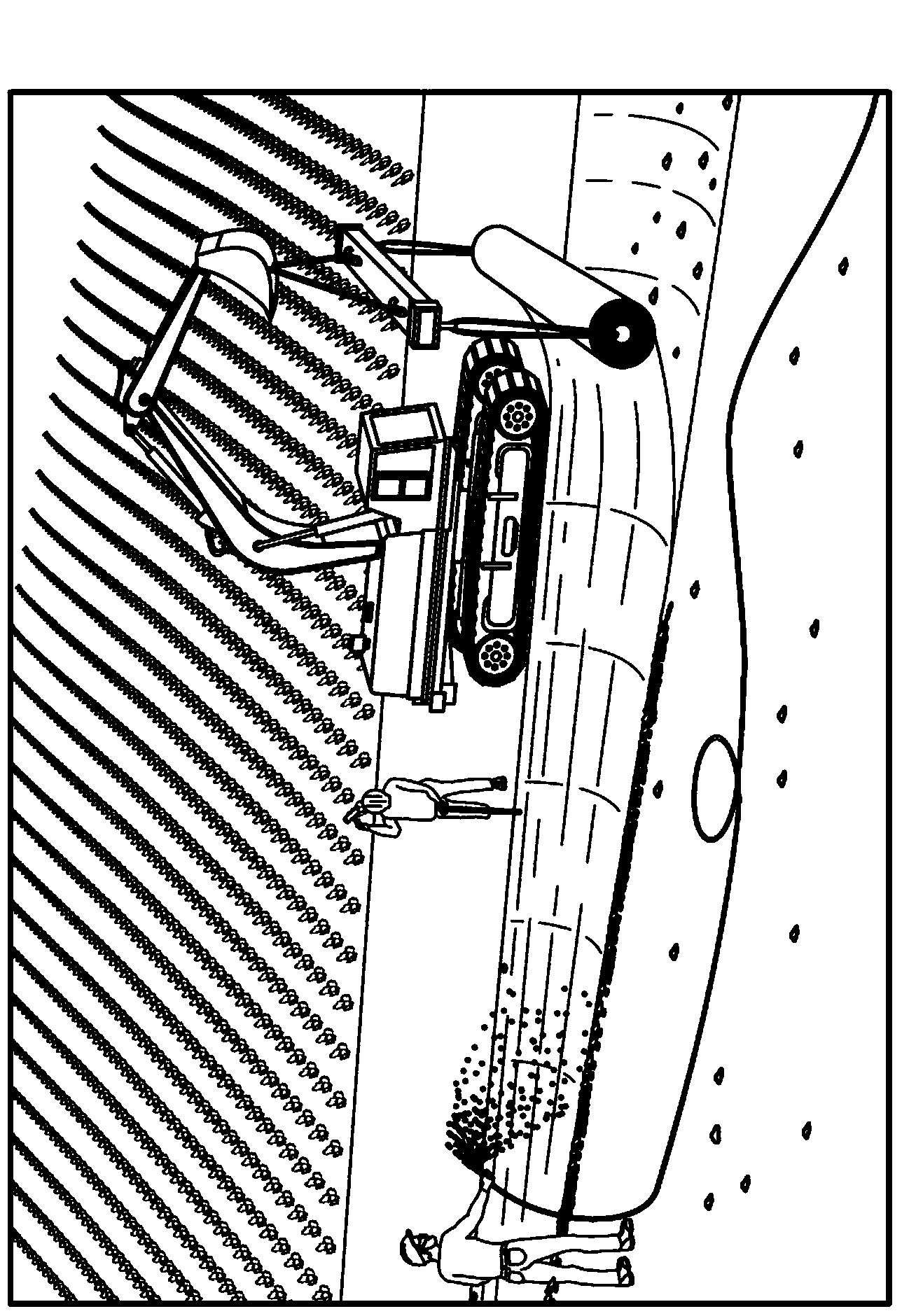

[0001] Cross References to Related Applications [0002] This application claims priority to U.S. Provisional Patent Application No. 61 / 554377, filed November 1, 2011, and U.S. Provisional Patent Application No. 61 / 703,618, filed September 20, 2012, No. 61 / 554377, which The entire content is hereby incorporated by reference. technical field [0003] This application relates to composites, including textile and fiber reinforced cementitious composites. In particular, the present application relates to flexible prefabricated textile and fiber reinforced cementitious composites capable of in situ (ie, in situ, in situ, at construction, etc.) hydration. Background technique [0004] In situ hydration enables liquids to be externally applied to and react with the cementitious material while the composite is arranged so as not to interfere with the properties of the prefabricated composite. This cementitious composite material allows for setting and hardening of the cementitious...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B32B5/02E04C5/07B28B7/46B28B23/00B32B5/26B32B27/12

CPCB32B2260/021B32B27/12B32B2255/26B28B19/0092B32B2264/10B28B23/0006B32B5/26B32B2262/0253B32B2260/044E04C5/07B32B5/022B32B2307/726B28B11/04B28B3/126B32B2419/00B32B2255/02B32B2597/00Y02E10/72

Inventor C·E·克拉斯诺夫B·摩巴舍A·博纳克达N·S·伯克D·S·李J·劳J·莫里斯M·法伊

Owner CORTEX COMPOSITES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com