A new type of core-pulling and demoulding mechanism for vacuum plastic mold of refrigerator liner

A technology of vacuum blister and refrigerator liner, which is applied in the field of core-pulling and demoulding mechanism of vacuum plastic mold for new refrigerator liner, to achieve the effects of reducing power output, increasing service life and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

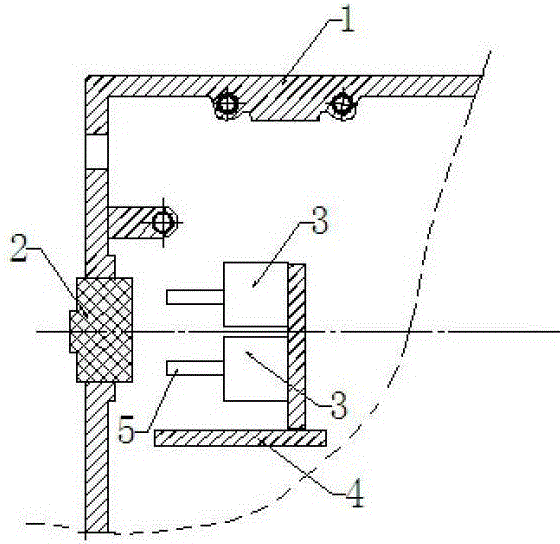

[0017] A new type of core-pulling and demoulding mechanism for a vacuum plastic mold for a refrigerator liner, comprising a mold body 1, a core-pulling block 2 and two cylinders 3, the core-pulling block 2 is movably installed on the mold body 1, The outer surface of the core block 2 opposite to the cylinder 3 and the friction surface with the mold body 1 are inlaid with a tin-brass alloy wear-resistant layer with a thickness of 0.1-1 mm to prevent the core block from being pulled from The process of mold body 1 being ejected and entering the core hole causes wear and tear, and there is a gap between the core hole and the core hole, which affects product performance;

[0018] The two cylinders 3 are fixedly installed in the mold main body 1 through the cylinder fixing seat 4, and are respectively installed on both sides of the radial center line of the core pulling block, and are symmetrically distributed; the piston rods of the two cylinders 5 are connected with the core-pull...

Embodiment 2

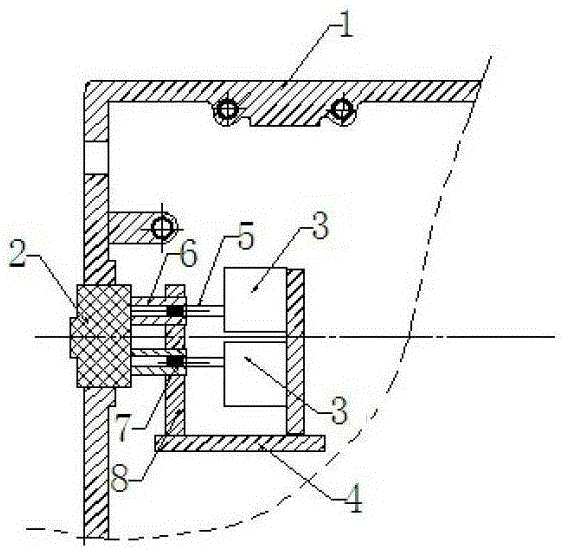

[0020] A new type of core-pulling and demoulding mechanism for a vacuum plastic mold for a refrigerator liner, comprising a mold body 1, a core-pulling block 2 and two cylinders 3, the core-pulling block 2 is movably installed on the mold body 1, The outer surface of the core block 2 opposite to the cylinder 3 and the friction surface with the mold body 1 are inlaid with a tin-brass alloy wear-resistant layer with a thickness of 0.1-1 mm to prevent the core block from being pulled from The process of ejecting the main body of the mold and entering the core hole causes wear and tear, and there is a gap between the core hole and the core hole, which affects product performance;

[0021] The two cylinders 3 are fixedly installed in the mold main body 1 through the cylinder fixing seat 4, and are respectively installed on both sides of the radial center line of the core pulling block, and are symmetrically distributed; wherein, the piston rods of the two cylinders 5. A connecting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com