Washing machine and outer drum thereof

A washing machine and outer tub technology, which is applied in the field of washing machines, can solve the problems of poor vibration and noise reduction effect of vibration damping components, increase the size of the washing machine, and cannot reduce damping force, etc., and achieves enhanced vibration damping and damping effects, simple structure, and self-efficacy. The effect of improving the deviation correction ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

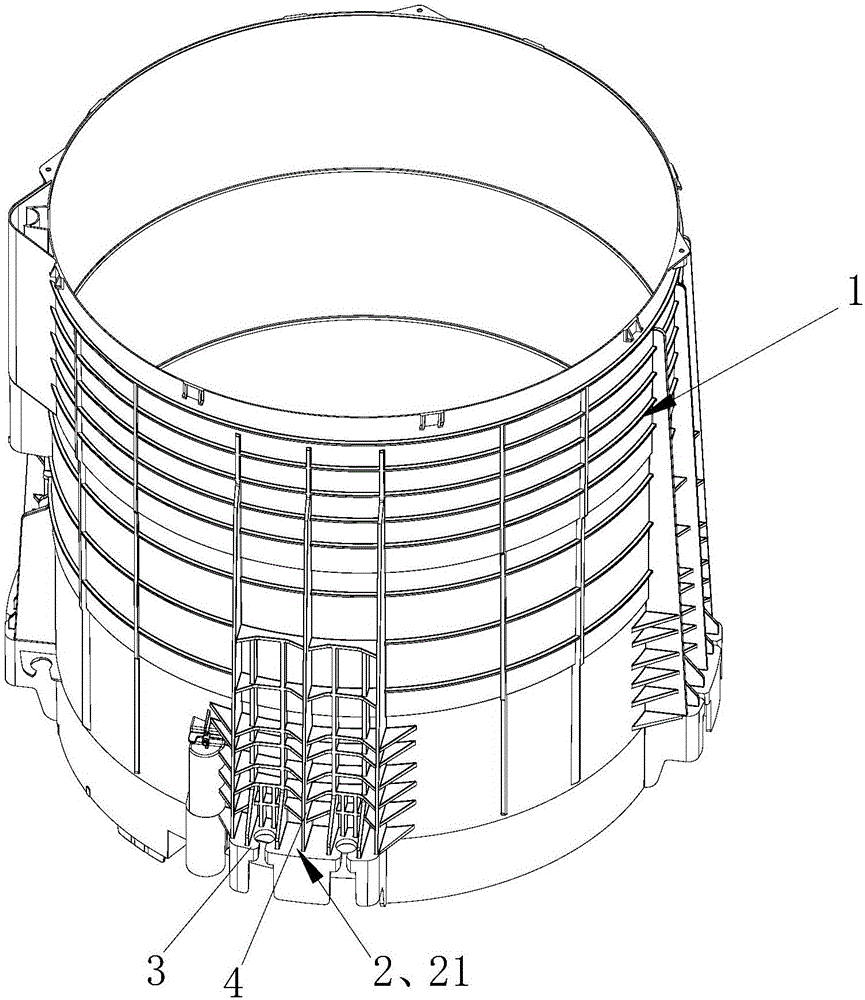

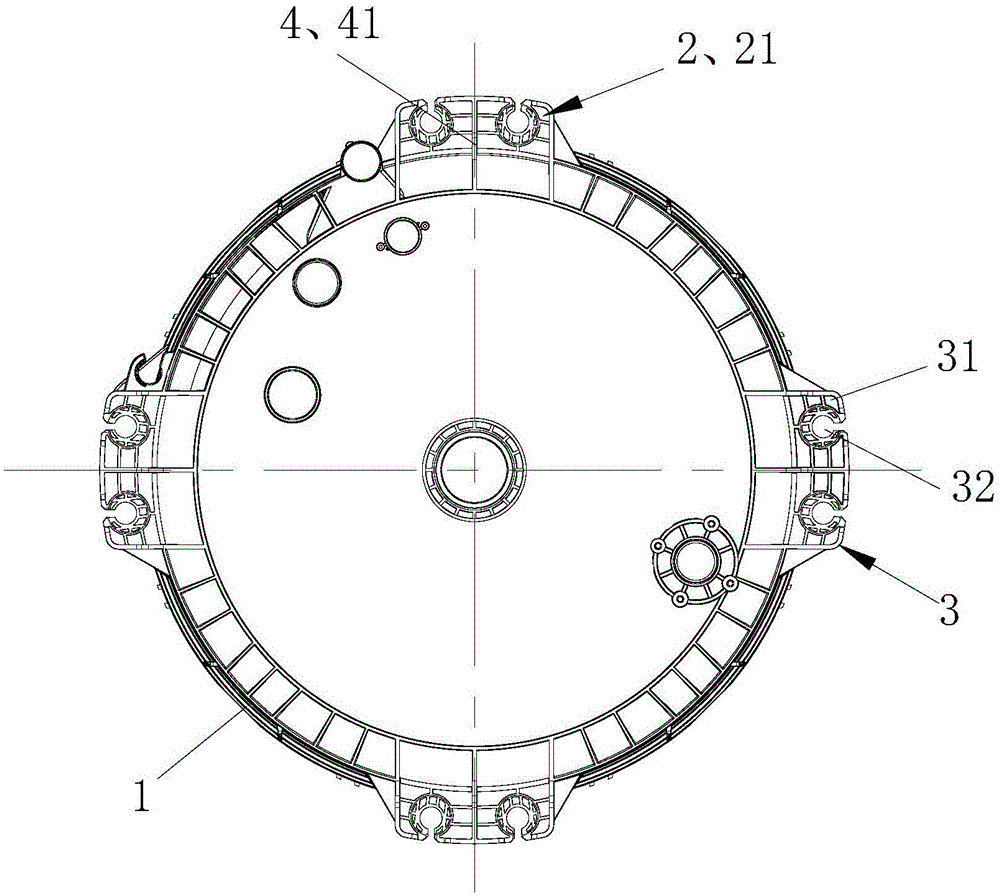

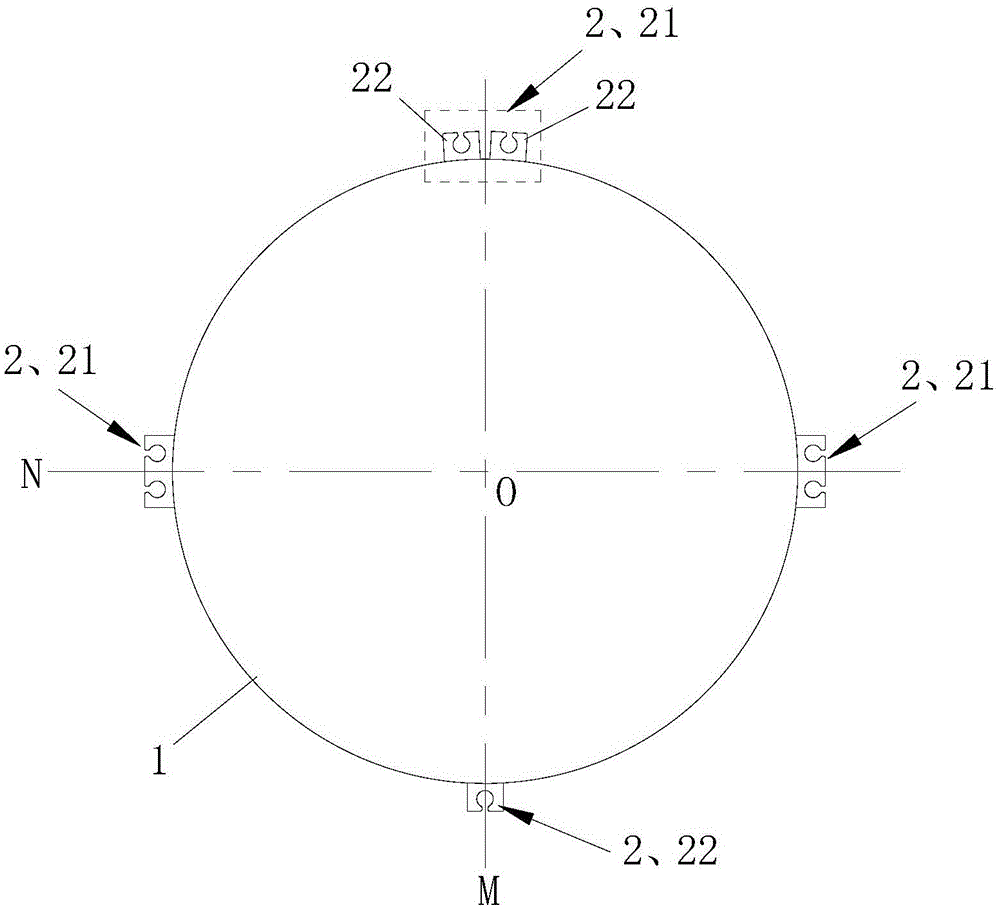

[0037] Such as Figure 2 to Figure 5 As shown, the four suspender mounting parts 2 described in this embodiment are evenly distributed along the circumference of the outer barrel, and the two oppositely disposed suspender mounting parts 2 are symmetrically arranged at the center O of the outer barrel.

[0038] Such as image 3 As shown, three single-hanging lug structures 22 and two double-hanging lug structures 21 are arranged on the circumference of the tub, and the two single-hanging lug structures 22 are combined into a suspender hanging part 2 .

Embodiment 2

[0040] Such as Figure 2 to Figure 5 As shown, the two hanging lugs 3 of the double hanging lug structure 21 of the present invention are axisymmetric structures, and the symmetry axes M and N intersect with the central axis of the outer barrel, that is, the symmetry axes M and N pass through the center O of the outer barrel.

[0041] Preferably, in the double hanging lug structure 21, the two hanging lugs 3 are integrally arranged. That is to say, there is the same base 31 , and two parallel hanging rod mounting holes 32 are arranged on the base 31 along the circumferential direction of the tub. Alternatively, the double lug structure 21 is composed of two independent single lug structures 22 (see image 3 ).

Embodiment 3

[0043] Such as figure 1 with figure 2 As shown, the suspender mounting part 2 of the present invention is integrally injected with the outer tub 1, and at least one reinforcing rib extending radially along the outer tub 1 is provided between the two suspender mounting holes 32 in the double-hanging lug structure 21. 4. Preferably, further, the two hanging rod hanging holes 32 in the double hanging lug structure 21 are arranged symmetrically along a reinforcing rib axis 41 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com