Shifting-force support device

A technology for supporting devices, shifting forces, applied in the direction of transmission control, elements with teeth, belts/chains/gears, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

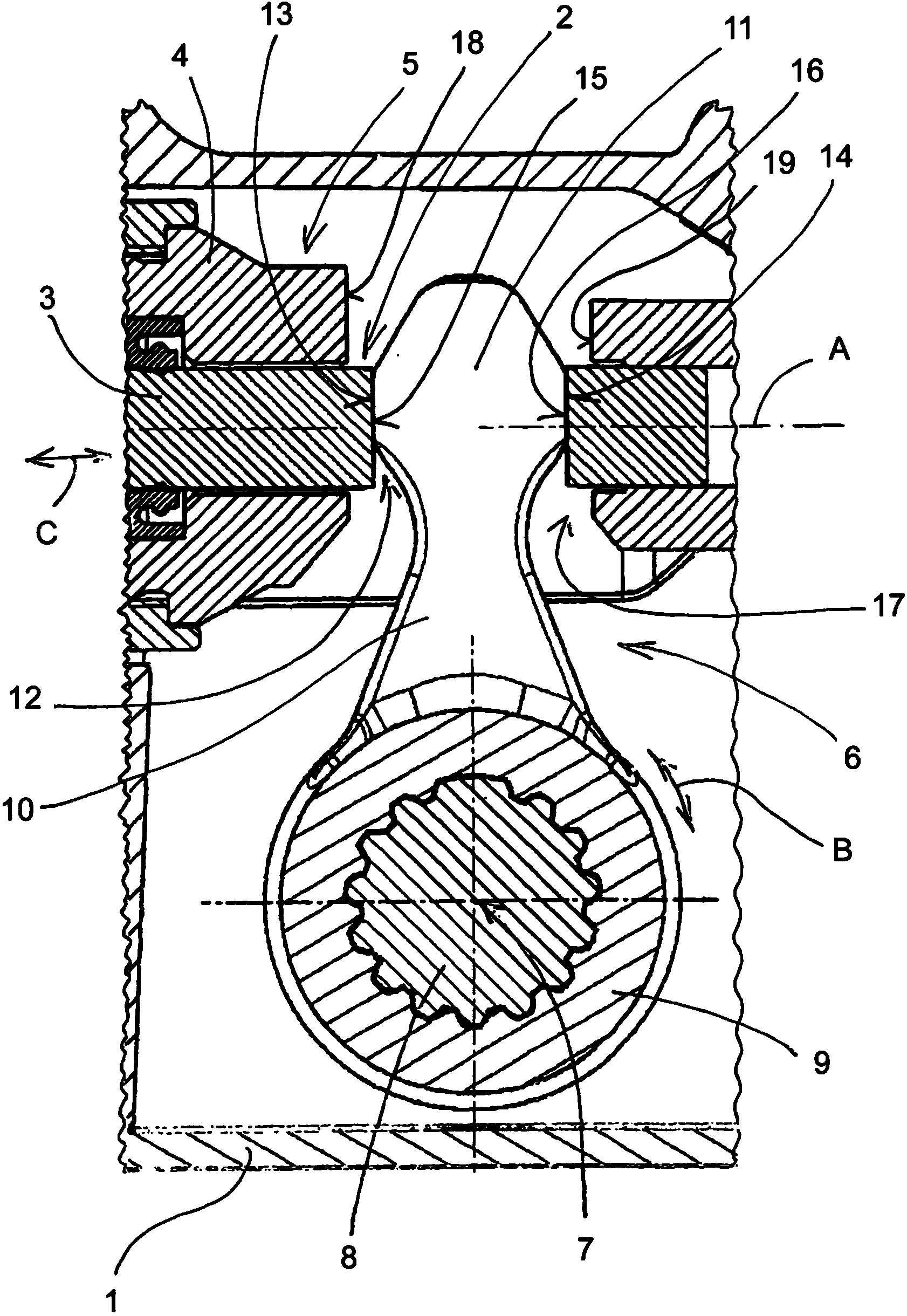

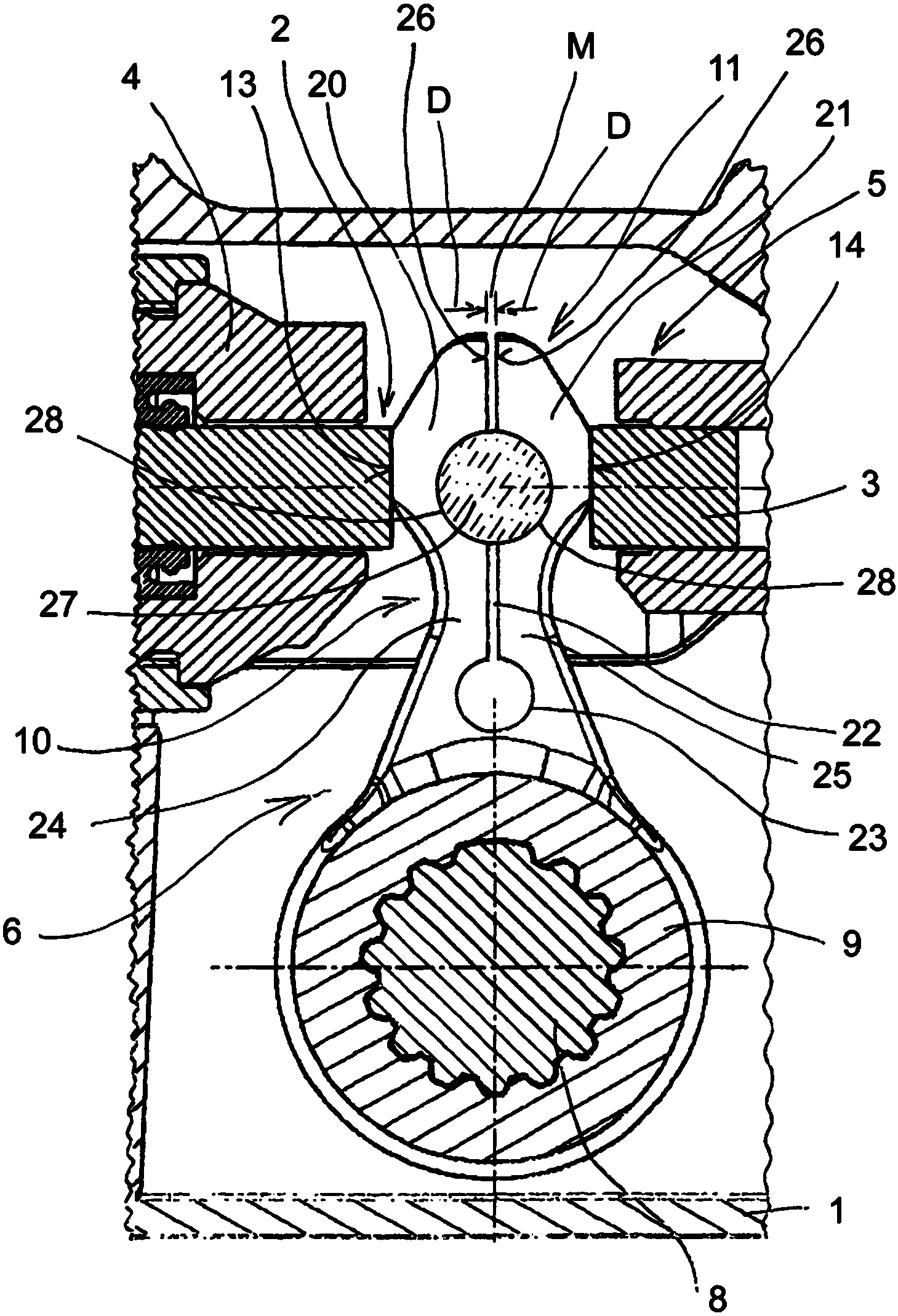

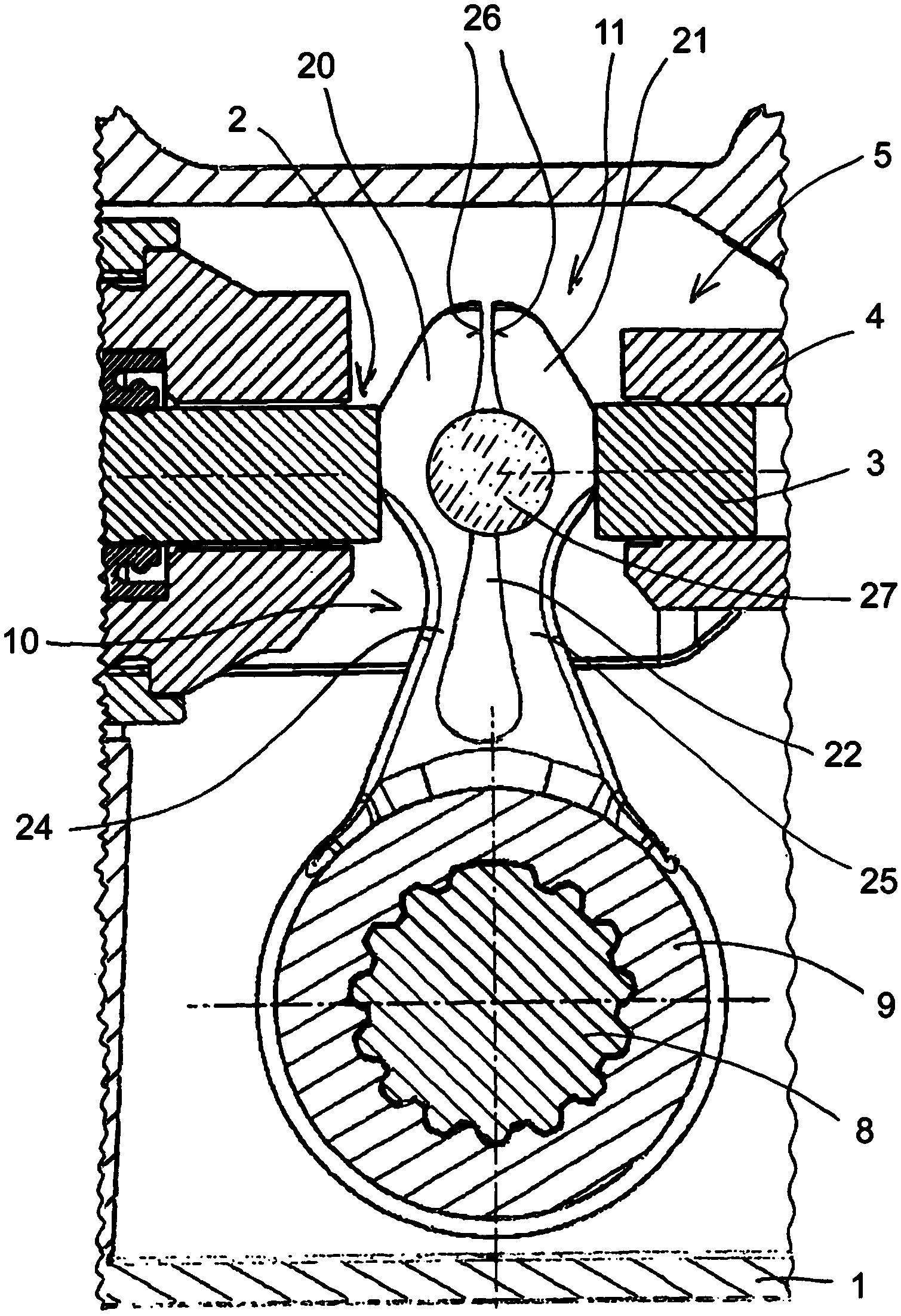

[0019] figure 1 The only areas of concern for conventional pneumatic shift force support devices for transmissions, which are mounted in the housing 1 and are movable relative to the housing 1 in the longitudinal direction A and which comprise sliding Block 2 , which is designed as a control rod 3 , which forms the input of the gearshift force support. The output of the shift force support is formed by the piston rod 4 , which surrounds the control rod 3 and is displaceable in the housing 1 relative to said control rod 3 in the longitudinal direction A and thus becomes the second slide 5 . .

[0020]A lever 6 is provided for actuating the control lever 3 , which is connected in a rotationally fixed manner to a shaft 8 (intermediate shaft) mounted rotatably about an axis 7 in the housing 1 , wherein for this purpose a hub 9 of the lever 6 and The shafts 8 engage one another in a form-fitting manner by means of corresponding contours. On the hub 9 of the lever 6 is formed an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com