Suspension

A suspension and installation groove technology, applied in the direction of power plant, jet propulsion device, internal combustion propulsion device, etc., can solve the problems of inability to effectively suppress large displacement vibration of the engine, and inability to effectively attenuate small vibration of the engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0028] The present invention will be described in detail below with reference to the accompanying drawings and examples.

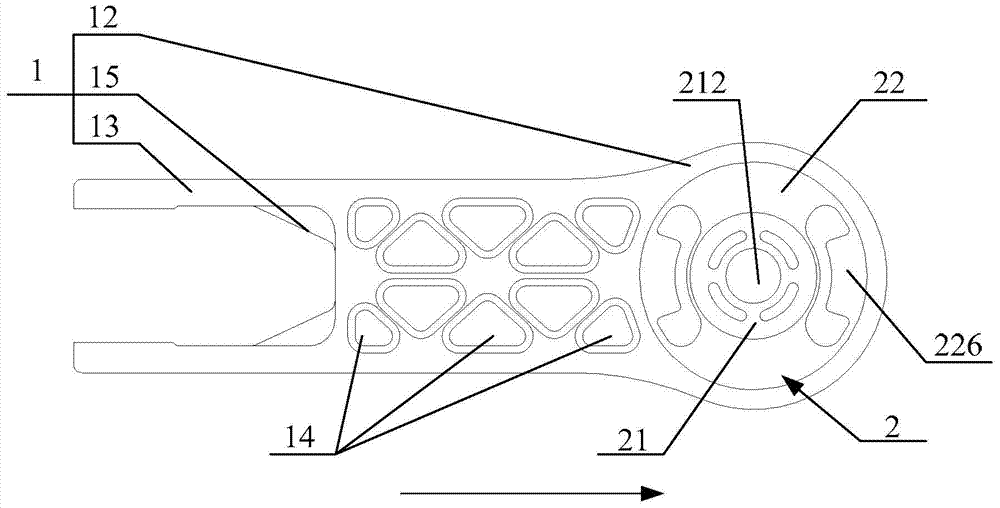

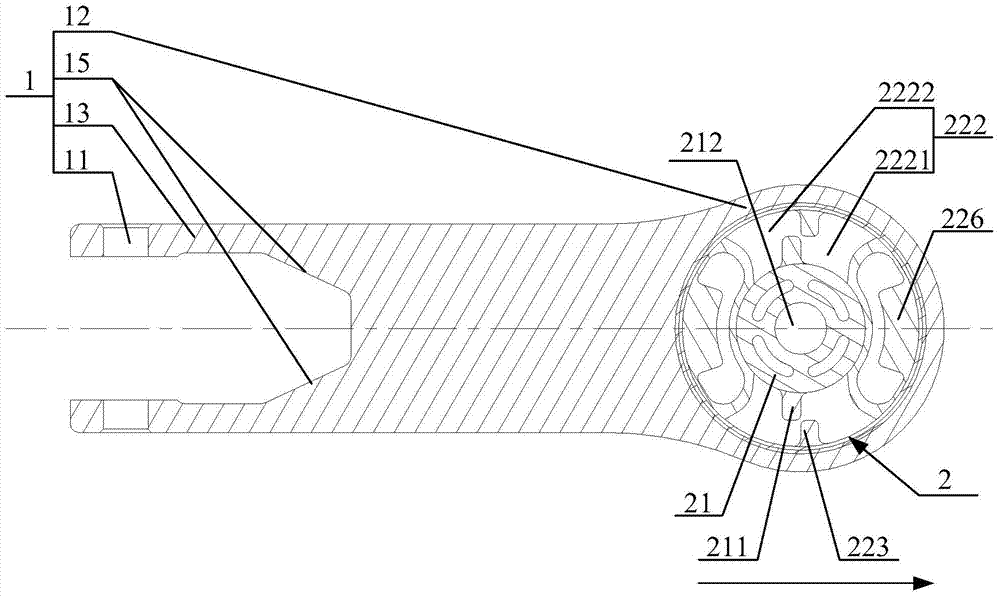

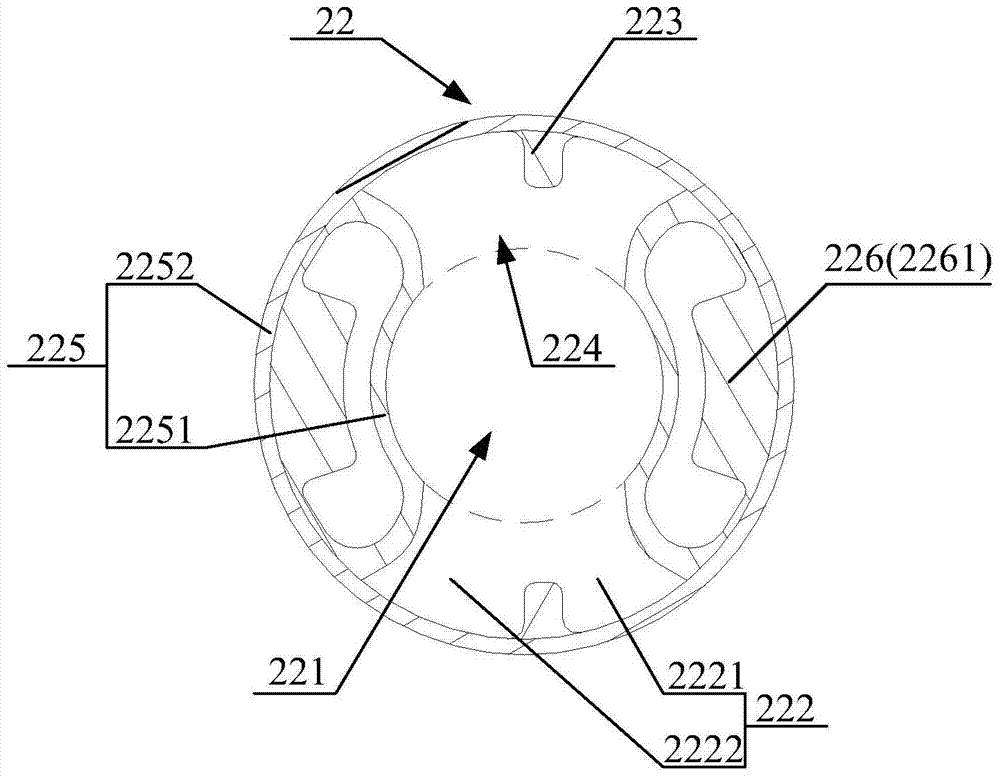

[0029] An embodiment of the present invention provides a suspension device, such as Figure 1-Figure 3 As shown, it includes a body 1, one end of the body 1 is provided with a shock absorbing structure 2 connected to the engine, and the other end is provided with a mounting hole 11 connected to the subframe; the shock absorbing structure 2 includes a connecting piece 21 fixedly connected to the engine, and An elastic shock absorber 22 with a mounting groove 221 and a cavity 222; the elastic shock absorber 22 is fixedly connected to the body 1, and the connector 21 is located in the mounting groove 221 and seals the cavity 222; the cavity 222 is filled with hydraulic oil The surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com