Electrolytic capacitor shell cooling coating containing rare-earth elements

A technology of electrolytic capacitors and heat-dissipating coatings, applied in coatings and other directions, can solve problems such as easy breakage, unstable power supply of electronic components, and hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

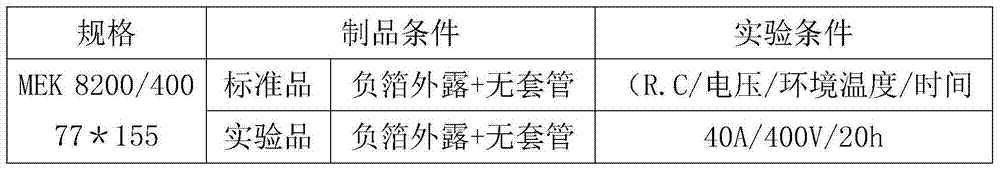

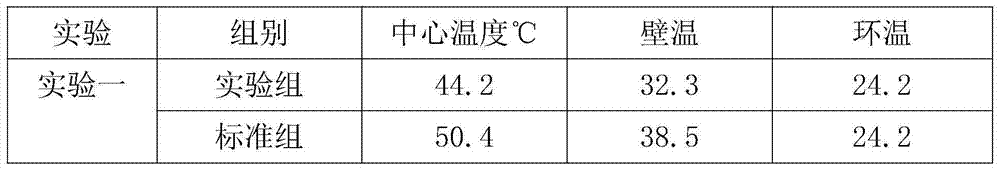

Embodiment 1

[0027] A heat-dissipating coating for electrolytic capacitor shells containing rare earth elements, consisting of the following components: 30 kg of water-soluble resin, 10 kg of rare earth oxide, 3 kg of purple sand, 4 kg of polyacrylamide, 5 kg of ceramic powder, ethylene glycol 5 kg, 5 kg of graphene, 2 kg of tourmaline, 3 kg of titanium dioxide, 5 kg of pigment, 50 kg of deionized water, 2 kg of trilead tetroxide, 3 kg of activated carbon, 2 kg of chloroplatinic acid, 5 kg of modified corn starch kg, sepiolite powder 0.5 kg, silicon nitride 2 kg, boron nitride 2 kg;

[0028] The preparation process of above-mentioned heat-dissipating coating is:

[0029] 1) Weigh each raw material according to the above ratio, use absolute ethanol as the dispersion medium for purple sand, tourmaline and activated carbon, wherein the mass ratio of material to ethanol is 1:20, and ultrasonically disperse on an ultrasonic cleaning machine for 1 hour;

[0030] 2) Put the ultrasonically disper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com