Shear wall and construction method thereof

A construction method and shear wall technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of insufficient horizontal bearing capacity, bending deformation and instability of steel rib plates, and overall structural damage of shear walls. The effect of improving the ability of horizontal shear force, increasing the horizontal bearing capacity, and enhancing the horizontal bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

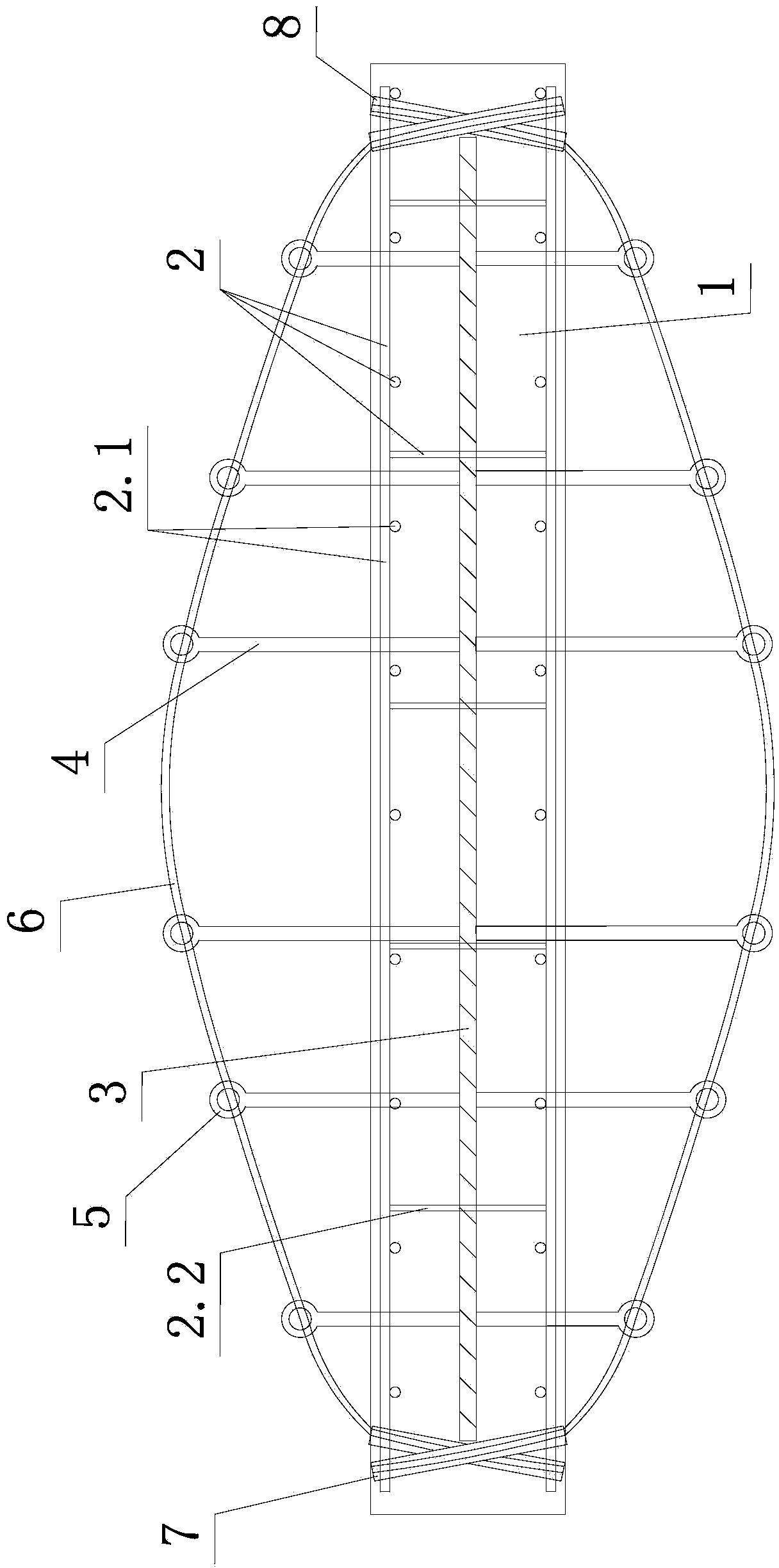

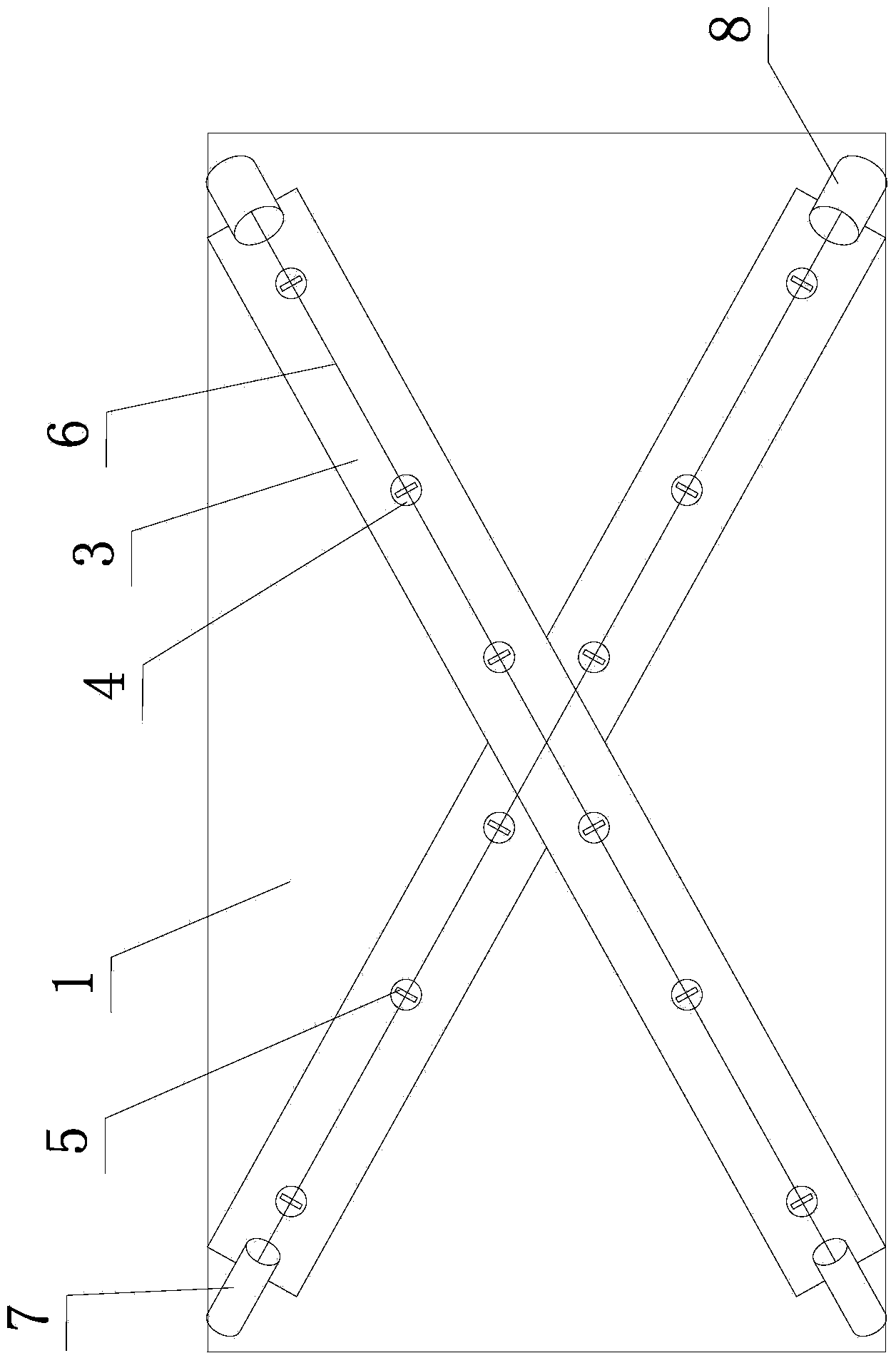

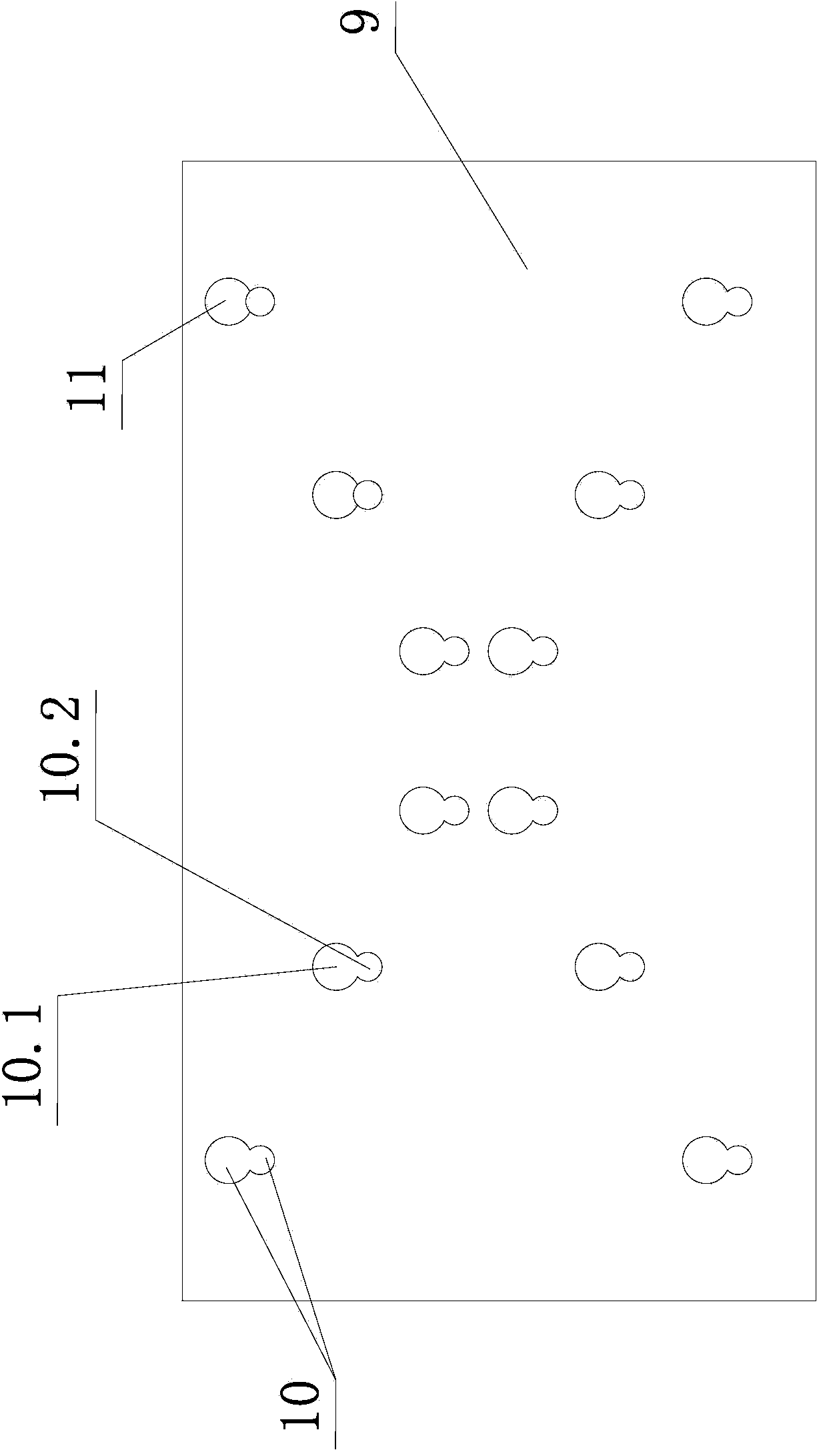

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown, the shear wall of the present invention, it comprises wall body 1. A reinforcement cage 2 and two intersecting steel ribs 3 are anchored in the wall 1 , and both steel ribs 3 are fixed with the reinforcement cage 2 . The inner surface and the outer surface of each steel rib 3 are fixed such as welding multiple guide pillars 4, and the multiple guide pillars 4 on the same surface of the same steel rib 3 are arranged along the width bisector of the steel rib 3 In a row, the shear wall has two steel ribs 3, and each steel rib 3 has two inner and outer surfaces, so that the shear wall has four rows of guide columns 4 in total. In every row of guide pillars 4, the guide pillars 4 in the middle are long and the guide pillars 4 on both sides are short, so as to form the bow-string ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com