Micro sound check valve

A check valve and valve body technology, applied in valve details, control valves, valve devices, etc., can solve the problems affecting the service life of the check valve and the pipeline, the pressure rise in the pipe, and the large impact force of the valve disc, so as to prolong the service life. , Eliminate water hammer and reduce the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

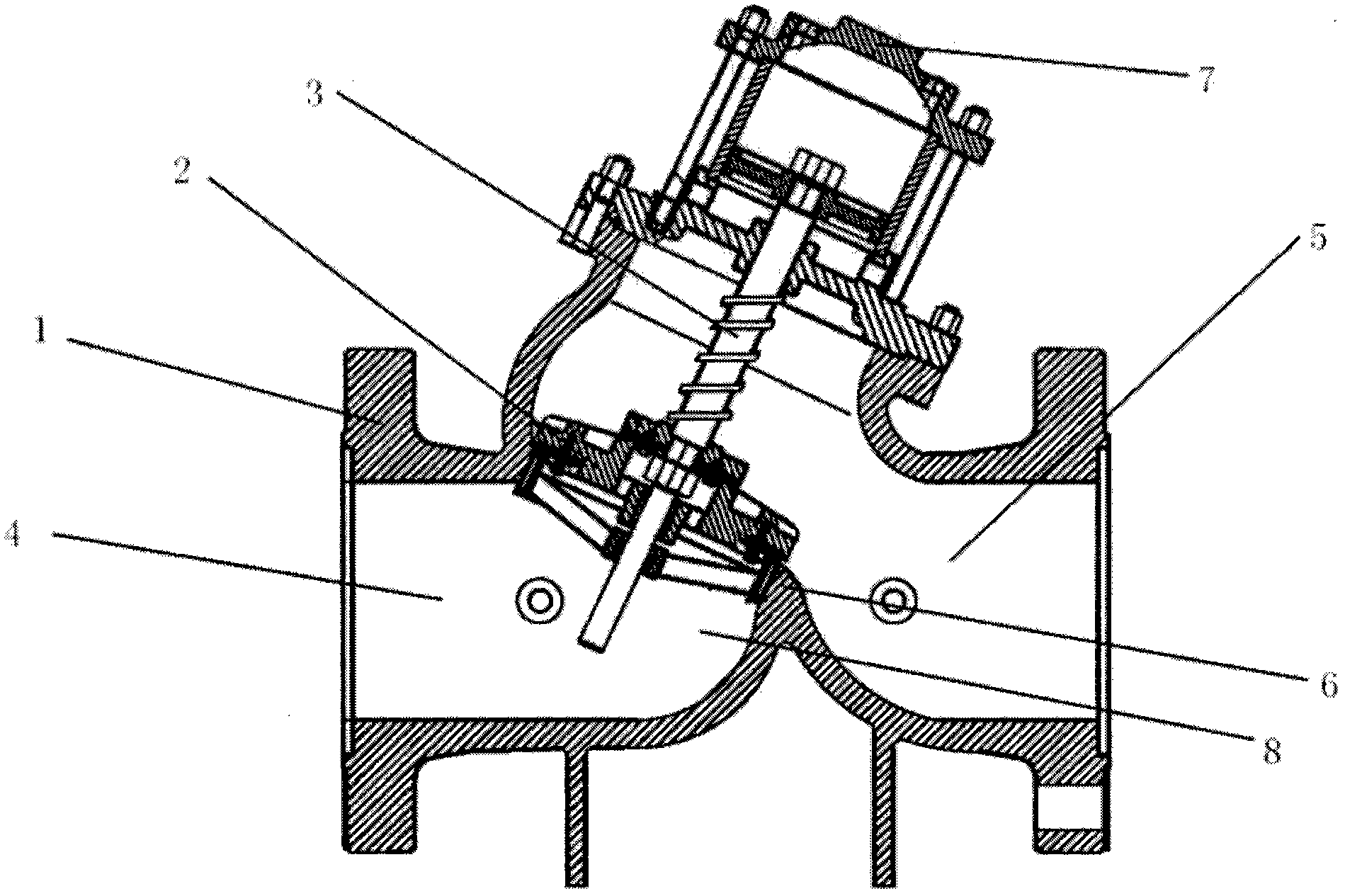

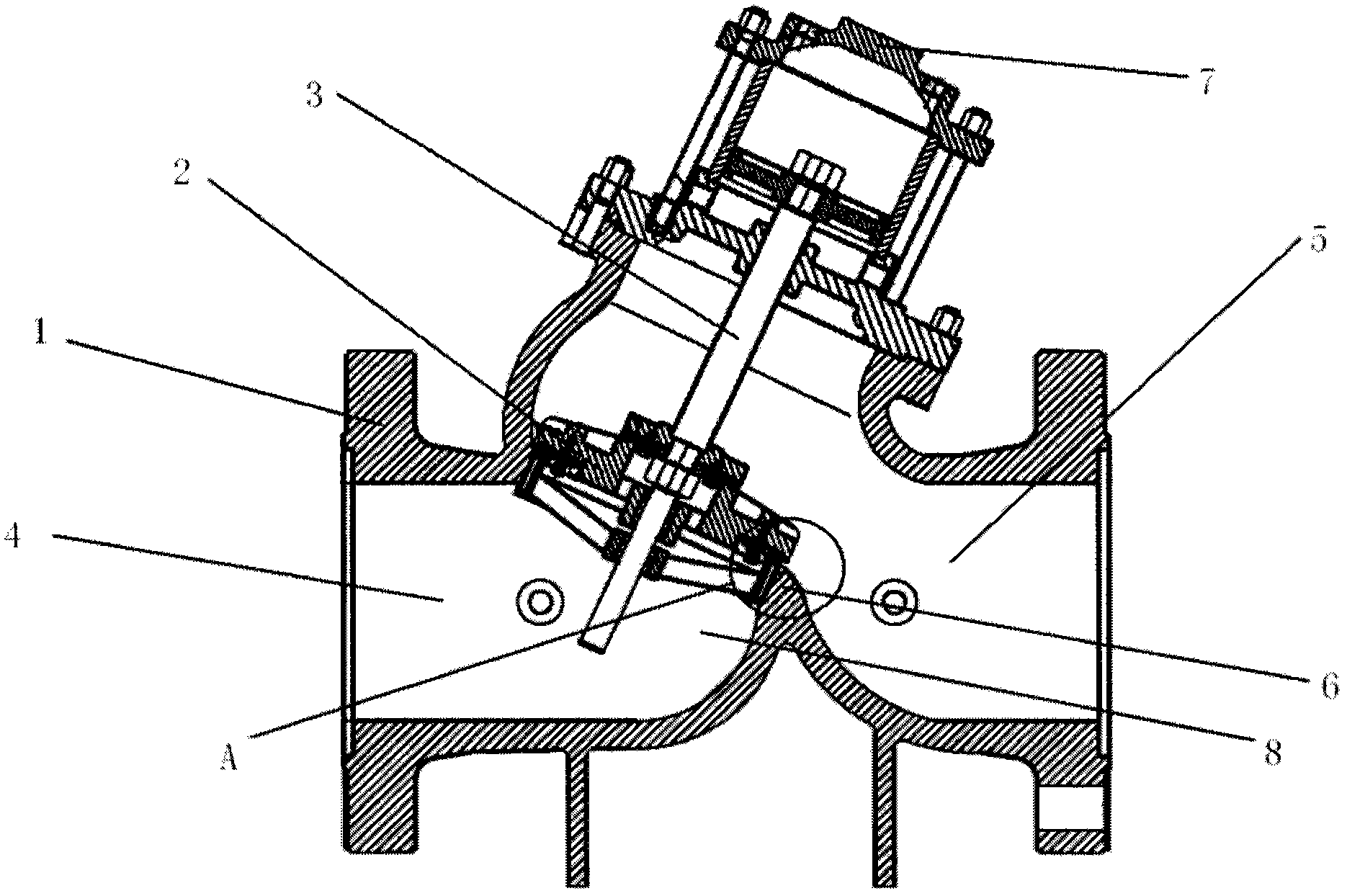

[0024] see figure 2 , the present invention relates to a micro-acoustic check valve, comprising a valve body 1 and a valve cover 7, the valve body is provided with a medium inlet 4 and a medium outlet 5, the medium inlet and the medium outlet are both connected to the The valve cavity 8 in the valve body is connected, the valve cavity is open and the valve cover is installed at the opening, a valve stem 3 is arranged in the valve cavity, and a valve disc 2 is sleeved on the valve stem. The connection between the medium inlet and the medium outlet is the connection port 6, and the valve disc is sealed with the connection port.

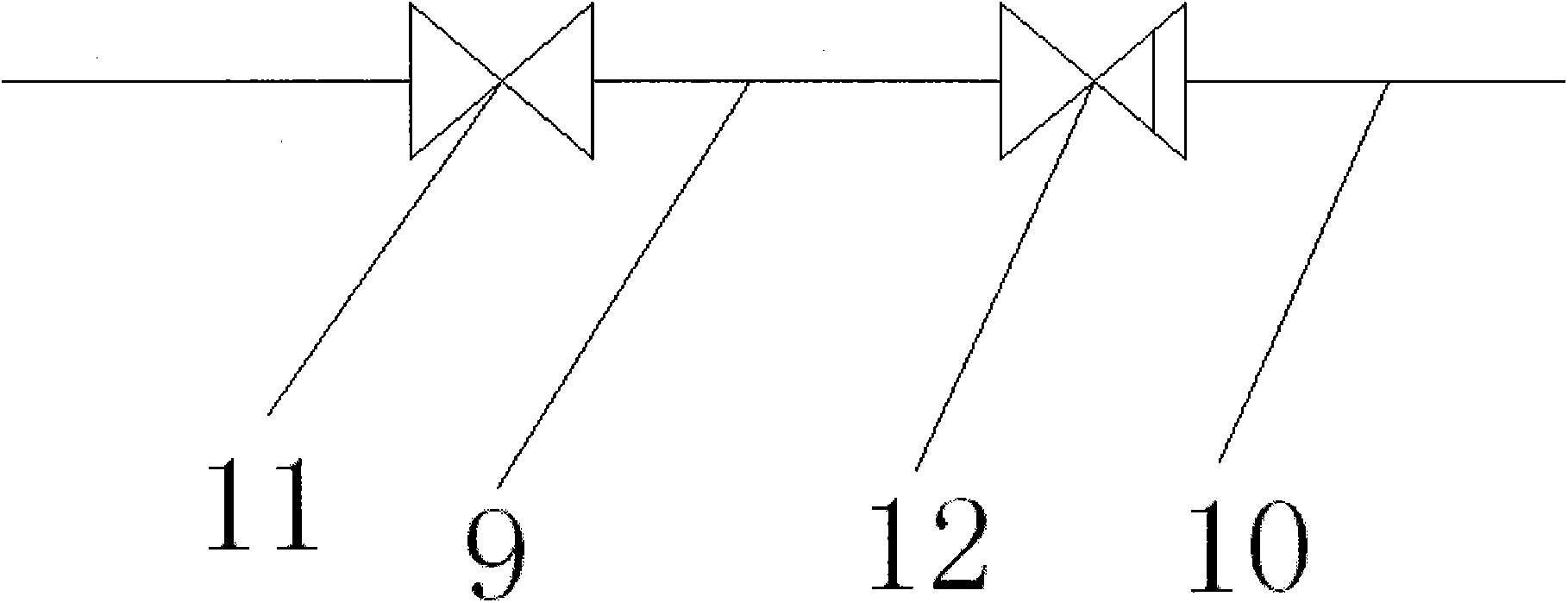

[0025] see image 3 , it should be noted that the present invention needs to be installed on the pipeline during actual use, the medium inlet channel of the micro-acoustic check valve is connected with the inlet pipeline 9, the medium outlet channel of the micro-acoustic check valve 12 is connected with the outlet pipeline 10, And a valve 11 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com