Anti-blockage flow guide expansion joint

An expansion joint, anti-clogging technology, applied in the field of expansion joints, to achieve the effect of high reliability, not easy to damage, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

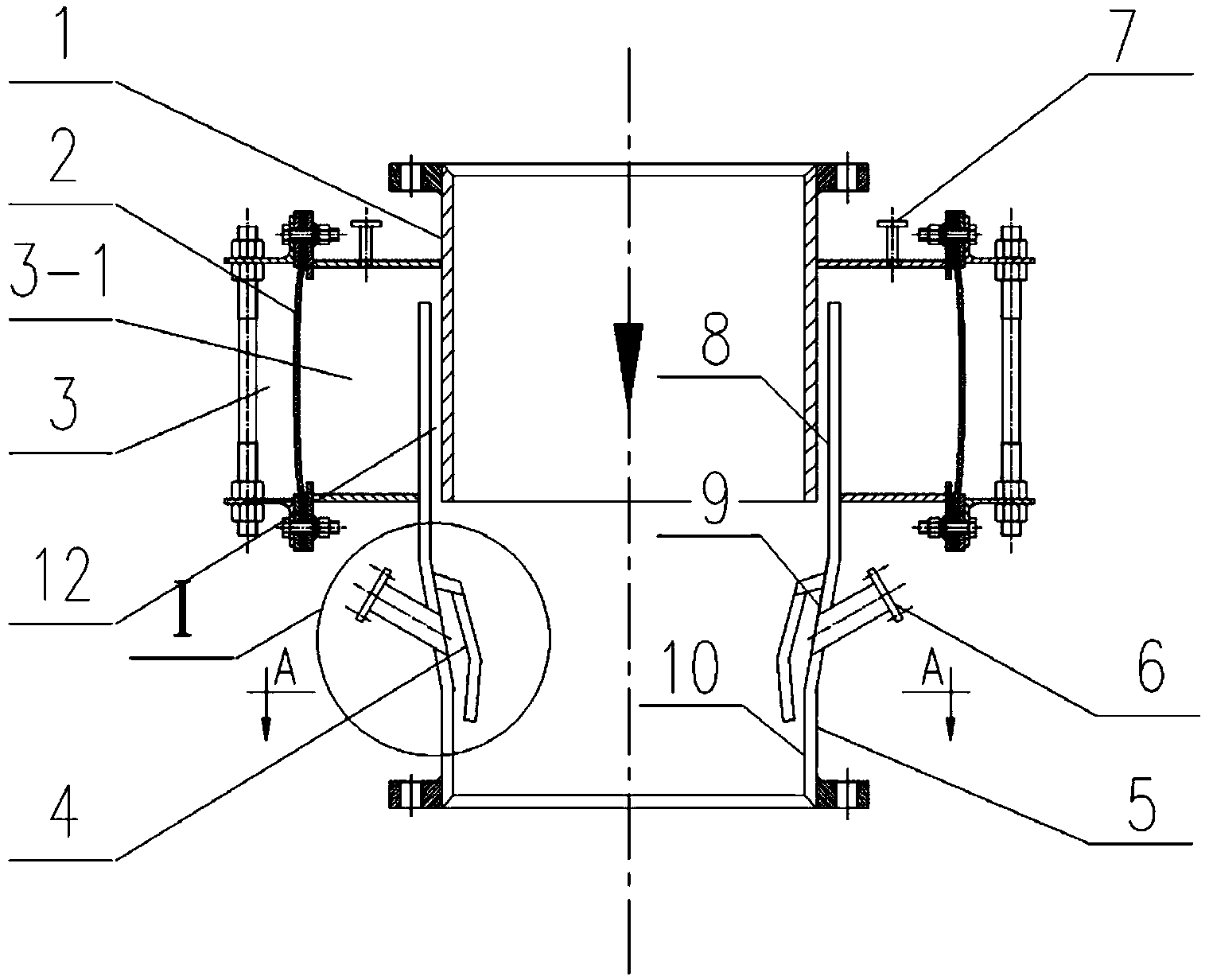

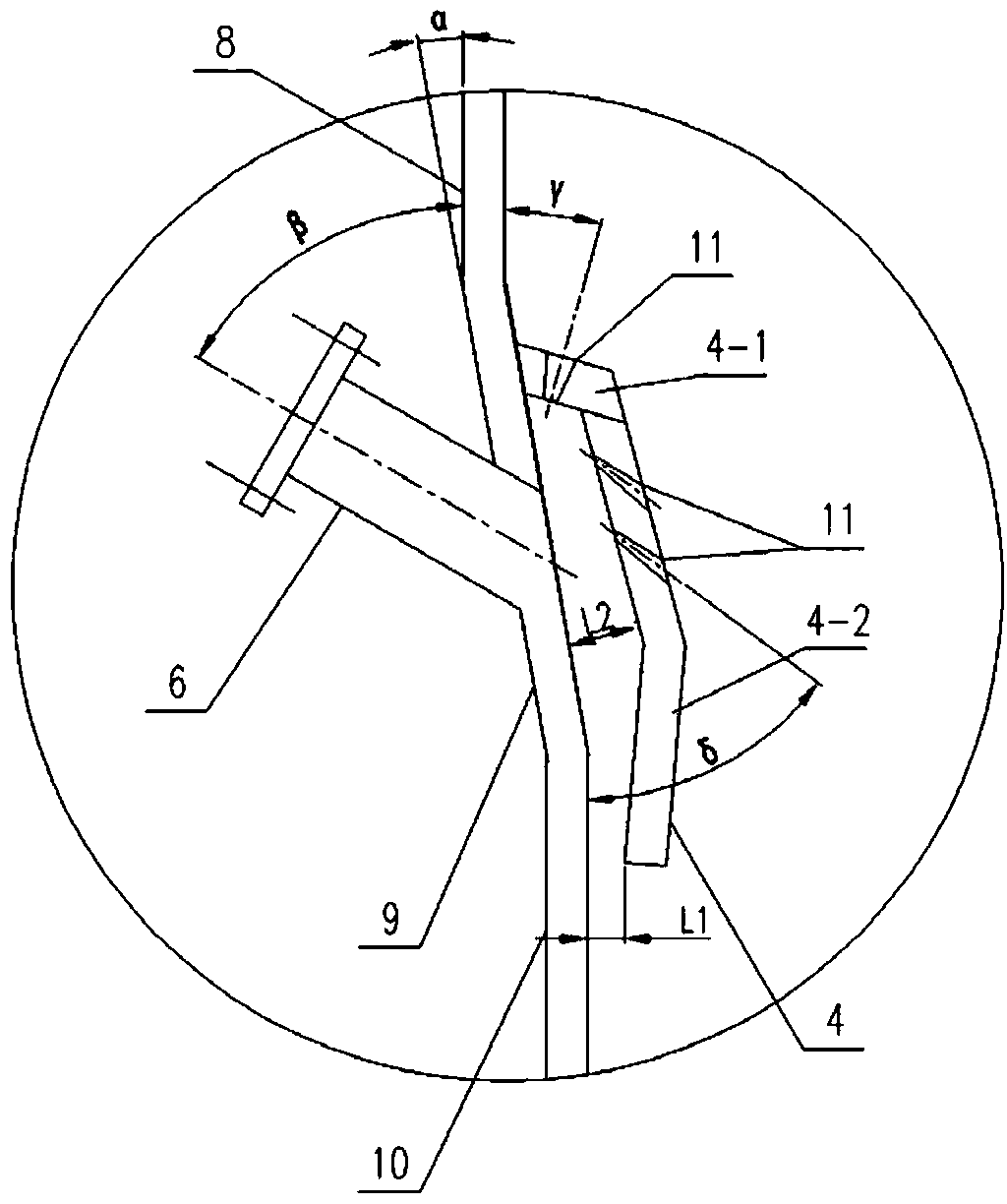

[0038] Embodiment 1: refer to Figure 1 to Figure 4 , the lower part of the inner ring 1 is fitted with the upper part of the outer ring 5, the outer ring 5 is composed of the upper part 8 of the outer ring, the middle part 9 of the outer ring and the lower part 10 of the outer ring, wherein the diameter of the lower part 10 of the outer ring is smaller than the diameter of the upper part 8 of the outer ring , the inclination angle α of the pipe wall in the middle part of the outer ring is 5-30°, and the sealing device 3 equipped with a non-metallic fabric skin 2 (or metal bellows) is installed on the outer part of the sleeve, and the non-metallic The sealed cavity 3-1 inside the fabric skin 2 is connected with a sealed tube 7, and the sealed cavity 3-1 communicates with the cavity in the outer ring 5 through the gap 12 where the inner ring 1 and the outer ring 5 are fitted. The gap between ring 1 and outer ring 5 is controlled at 1-20mm. A plurality of guide tubes 6 are conn...

Embodiment 2

[0046] Except that the guide device is different from that in embodiment 1, all the others are the same as in embodiment 1. The flow-guiding device is a flow-guiding inner tube 13 installed on the inner wall surface of the outer ring middle part 9, the inlet of the flow-guiding inner tube 13 communicates with the outlet of the flow-guiding tube 6, and the flow-guiding inner tube 13 The outlet of the outlet is vertically downward along the wall surface of the outer ring 5. Further, a plugging port 11 may also be provided on the flow guiding inner tube 13 as required. The diversion wind drawn from the diversion pipe 6 is drawn out through the outlet of the blowing plugging port 11 and the diversion inner pipe 13 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap