Liquid level display device

A display device and liquid level display technology, applied in buoy liquid level indicators, packaging, transportation and packaging, etc., can solve the problems of reducing the visual effect and affecting the normal operation of machinery and equipment, and achieve a wide range of popularization, liquid level reading Get fast and accurate results with less structural changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

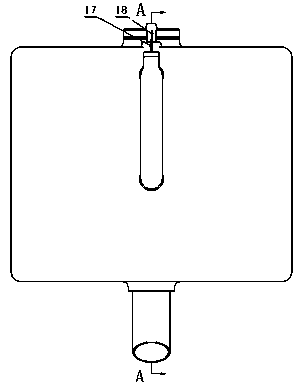

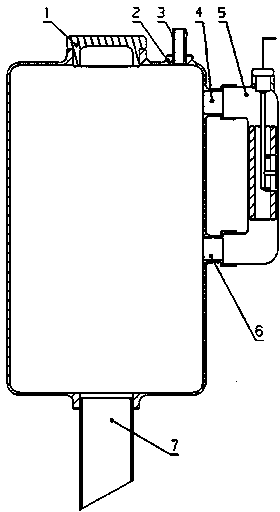

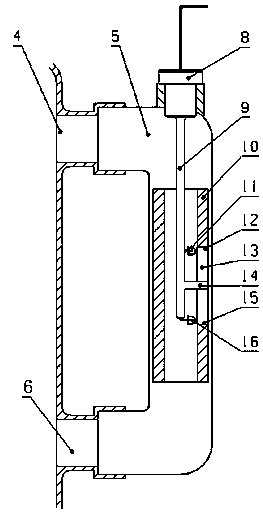

[0023] Example 1, such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a liquid level display device of the present invention includes a liquid level display device body (5), which is installed on the outside of the liquid storage tank body (2), and the liquid storage tank body (2) includes a water outlet (7), a plug The cover (1), the drain port (3), and the water outlet (7) are connected with the working equipment to provide the working equipment with continuous pressure and supplement after liquid consumption. In the body (5) of the liquid level display device, an upper communicating water port (4) and a lower communicating water port (6) are provided, and a float (10) is provided at the same time. The float (10) is a middle-pass structure, and a side window (13) along the vertical direction is opened on the side of the float (10), and an upper edge (12) of the side window is provided above the side window (13), and a side window Window lower edge (15). A plug...

Embodiment 2

[0027]Embodiment 2, a liquid level display device, including a blocking cover, a liquid storage tank body, a drain port, an upper connecting water port, a display device body, a lower communicating water port, a water outlet, a plug, a wire installation rod, a float, a green light-emitting diode, The upper edge of the side window, the side window, the limit rod, the lower edge of the side window, the red light-emitting diode, the first wire, and the second wire are characterized in that there is a blocking cover (1) on the top of the liquid storage tank body (2), and a Drain port (3), there is a water outlet (7) under the liquid storage tank body (2), the display device body (5) is installed on the outer side of the liquid storage tank body (2), and the upper part of the display device body (5) is connected The water port (4) is connected to the liquid storage tank body (2), and there is a lower communication port (6) under the display device body (5) to communicate with the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com