Spring damping energy dissipation and vibration reduction beam string structure, roof system and construction method

A technology of spring damping and spring damper, which is applied to girders, joists, roofs, etc., can solve the problems of large tension jack travel, high equipment requirements, and complicated equipment, so as to ensure installation stability and compensate for the reduction of cable force , to avoid the effect of fatigue damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

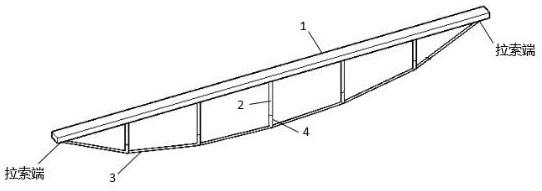

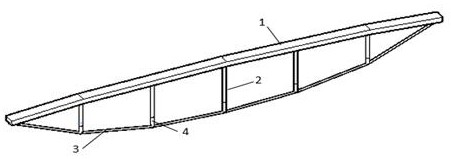

[0048] This embodiment provides a spring-damped energy-dissipating vibration-damping string beam structure, such as figure 1 and figure 2 As shown, it includes upper run beam 1, damping strut assembly and stay cable 3, the stay cable 3 is connected between the two ends of the upper run beam 1, and a plurality of damping stay assemblies are arranged at intervals along the length direction of stay cable 3, and the damping stay assembly is connected In the tension area formed by the top run beam 1 and the stay cable 3.

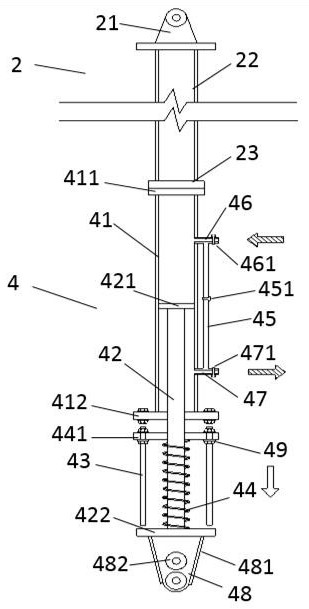

[0049] Specifically, the damping strut assembly includes a strut 2 and a spring damper 4 , the strut 2 is a standard strut, one end of the strut 2 is hinged to the upper string 1 , and the other end of the strut 2 is connected to the spring damper 4 . As shown in Figure 3(a) and Figure 3(b), the strut 2 includes a steel pipe main body 22, a connecting plate 21 connected to one end of the steel pipe main body 22, and an end plate 23 connected to the other end of...

Embodiment 2

[0065] This embodiment provides a spring-damped energy-dissipating and vibration-reducing string beam structure, which differs from Embodiment 1 in that the arrangement of springs 44 is different, as shown in Figure 4(b) and Figure 5(c), the second flange A plurality of springs 44 are connected between the disk 441 and the end plate 422 , and four or more springs 44 are distributed along the circumferential direction of the second flange 441 .

[0066] Other structures are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0068] This embodiment provides a construction method for a spring-damped, energy-dissipating, and vibration-reducing tensioned string beam, using the stringed beam structure described in Embodiment 1 or Embodiment 2, including:

[0069] A. Assemble the upper string beam 1 on the temporary support frame.

[0070] B. The damping strut assemblies are sequentially connected at the corresponding positions of the upper string 1 , and the lengths and bearing capacities of the damping strut assemblies at different positions of the upper string 1 are different.

[0071] C. Connect one end of the cable 3 with the cable node at one end of the upper string beam 1, and then connect with the splint node 48 at the lower end of the spring damper 4 in turn, and finally connect the other end of the cable 3 with the cable at the other end of the upper string beam 1 node connection.

[0072] D. First construct the damping strut assembly in the middle position. Connect the oil outlet pipe of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com