Charging system and method of belt conveyer inspection system

A belt conveyor and inspection system technology, applied in the direction of collectors, electric vehicles, electrical components, etc., can solve the problems that affect the real-time monitoring of the conveyor, easily cause missed inspection, and large workload, and reduce the labor intensity of workers. , avoid loopholes, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

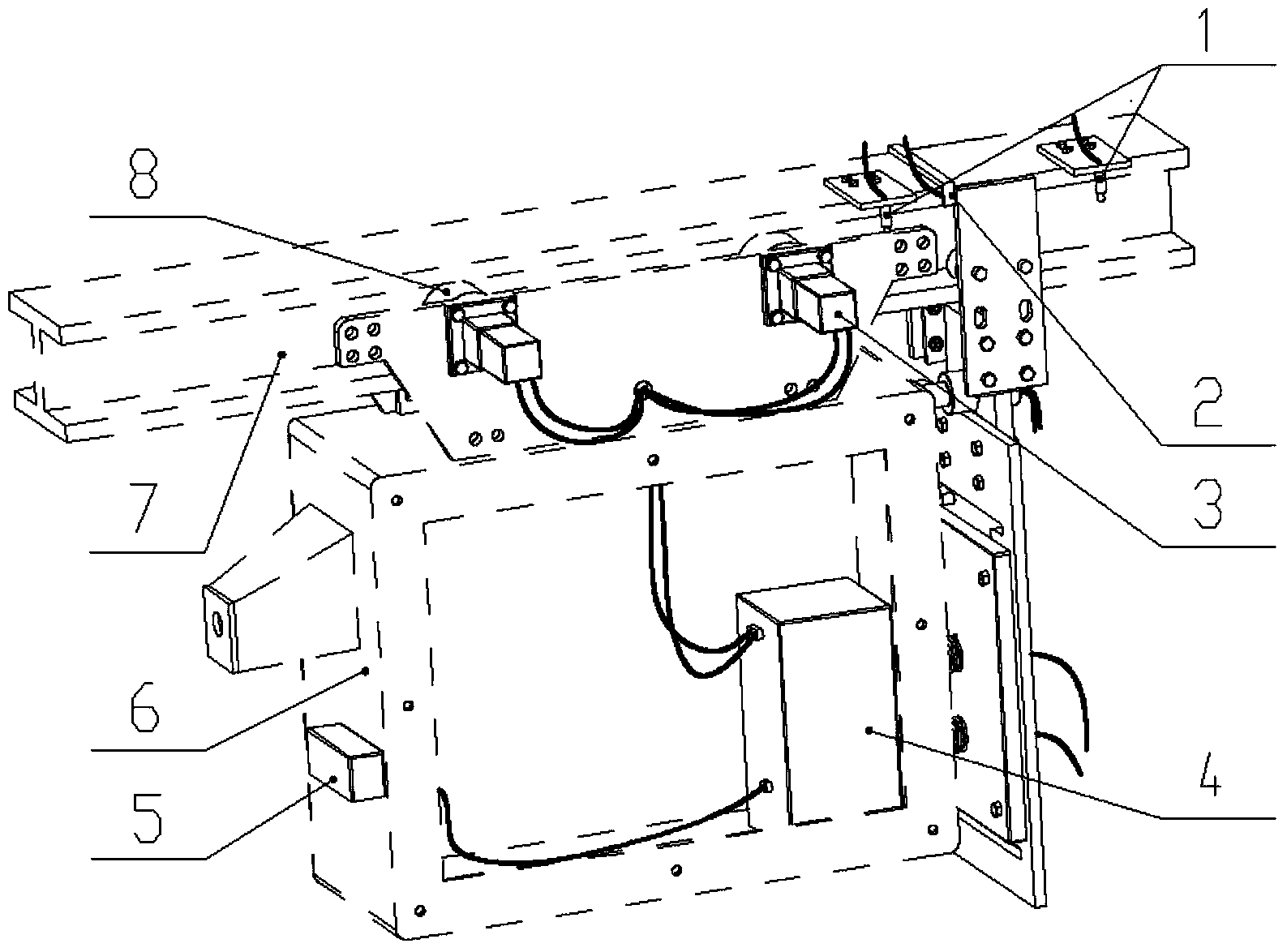

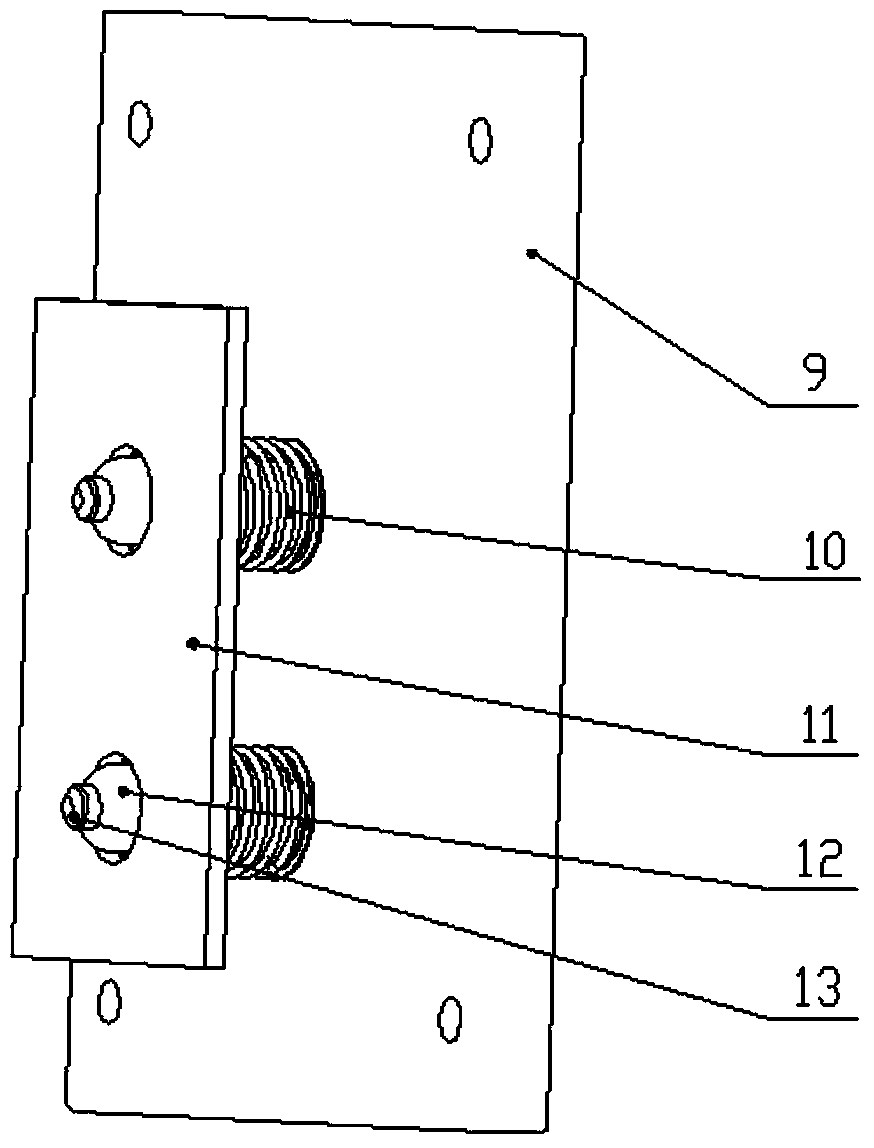

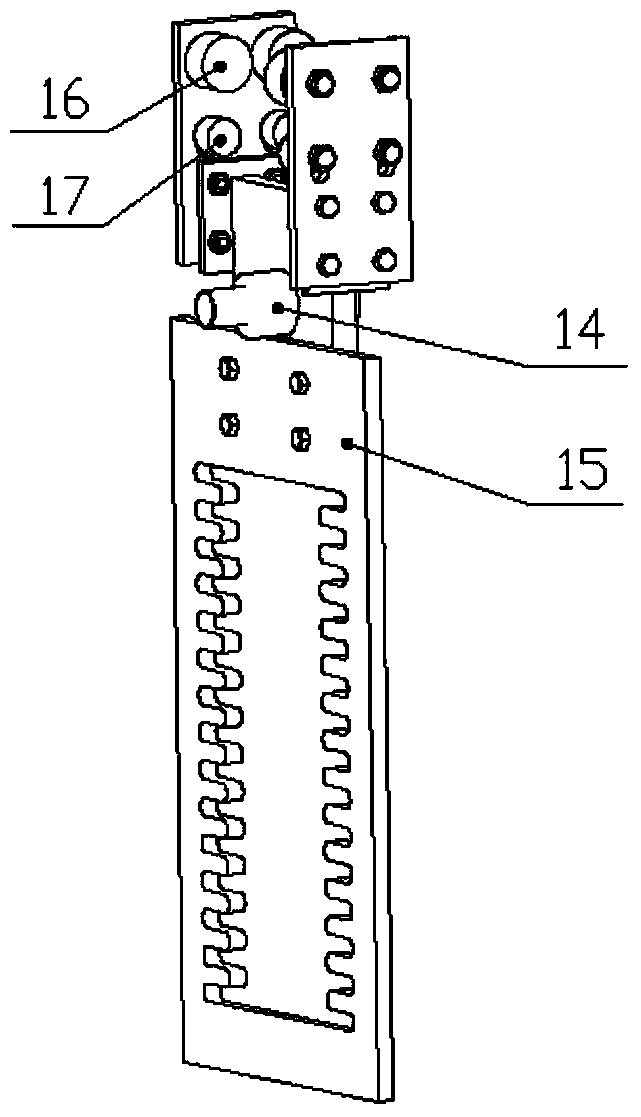

[0022] Such as figure 1 As shown, the charging system of the belt conveyor inspection system of the present invention includes a real-time charging unit and a starting end charging unit; Roller 8 constitutes. The stroke switch 1 is arranged on the guide rail 7 to control the stroke of the inspection bin of the belt conveyor. The battery iron control switch 2 is located at the upper end of the guide rail 7 and between the two travel switches 1 . Described real-time charging unit comprises speed-up generator generator 3, links to each other with speed-up generator generator 3 and is arranged on the rechargeable battery 4 in belt conveyor inspection storehouse casing 6, and the output shaft of speed-up speed generator generator 3 is provided with There are rollers 8 that can reciprocate in the guide rail 7. There are two speed-up generators 3, which are ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com