Automatic gluing device for chain zipper

A gluing device and gluing technology, applied in the direction of surface coating liquid device, coating, surface pretreatment, etc., can solve the problems of lack of full automation, etc., and achieve the effect of reliable principle, easy control and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

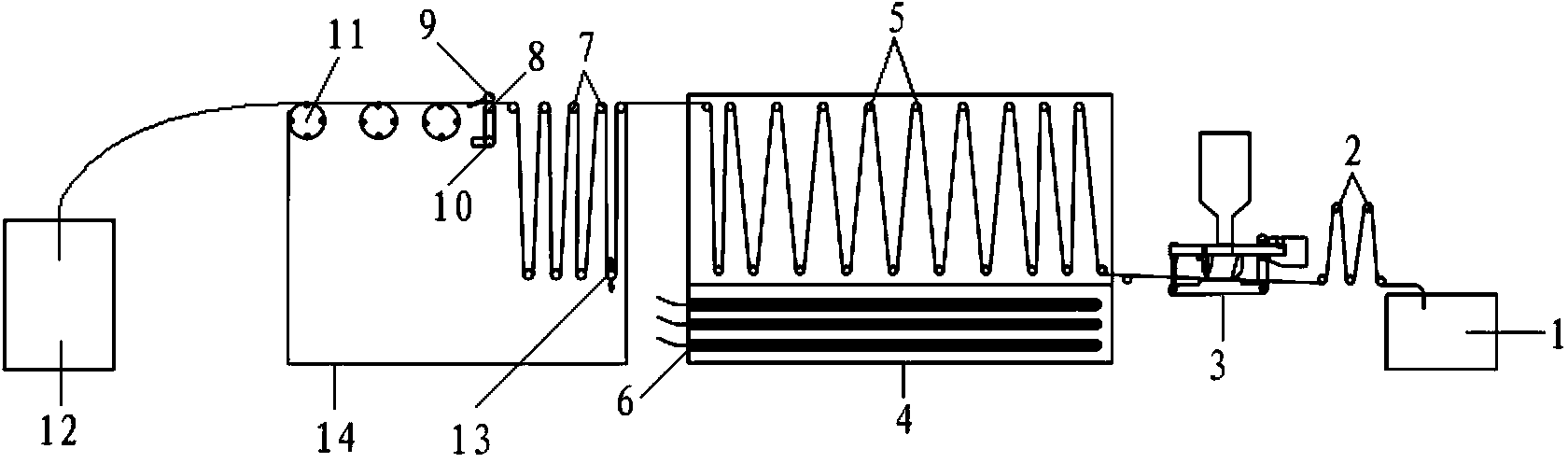

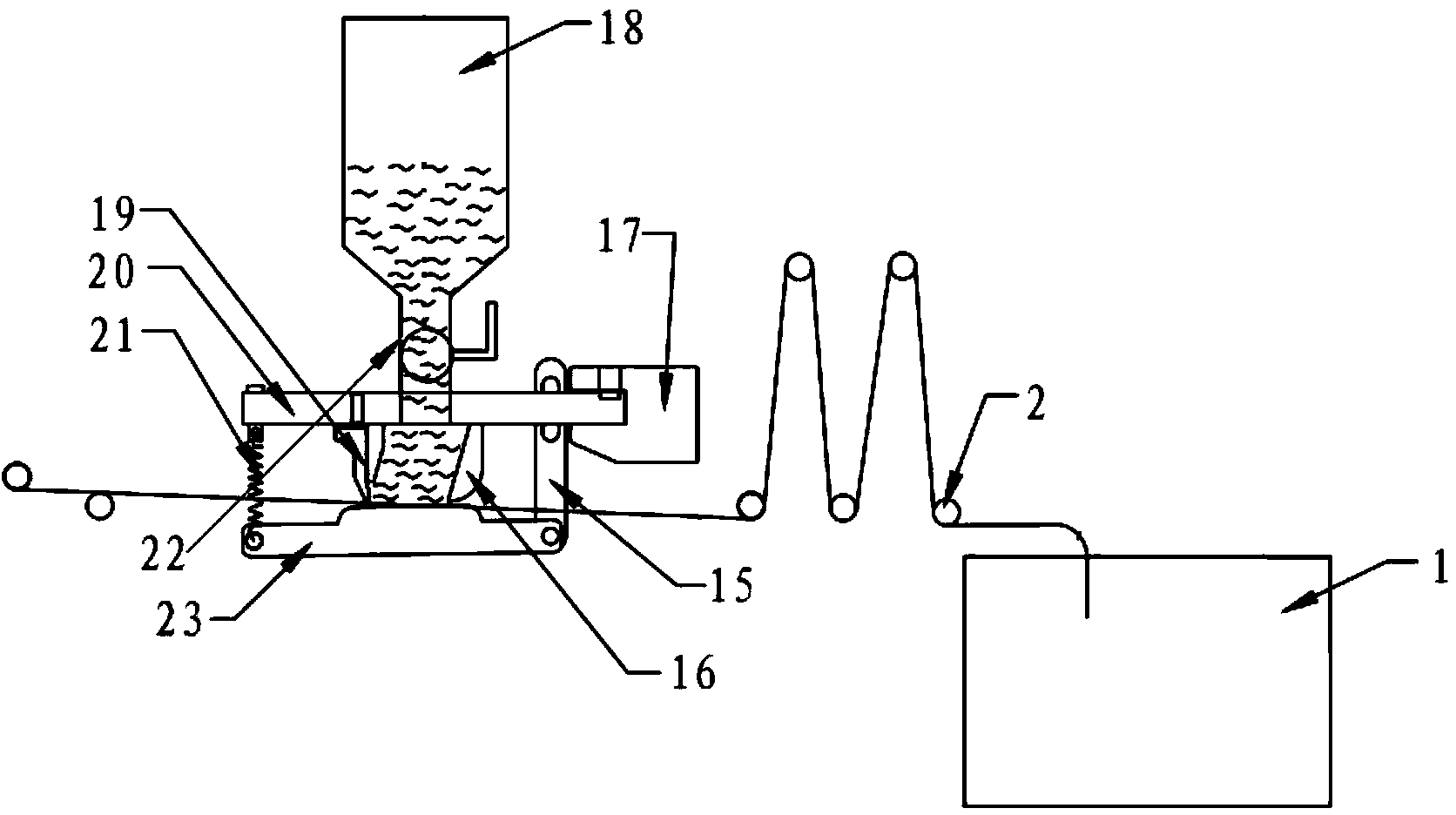

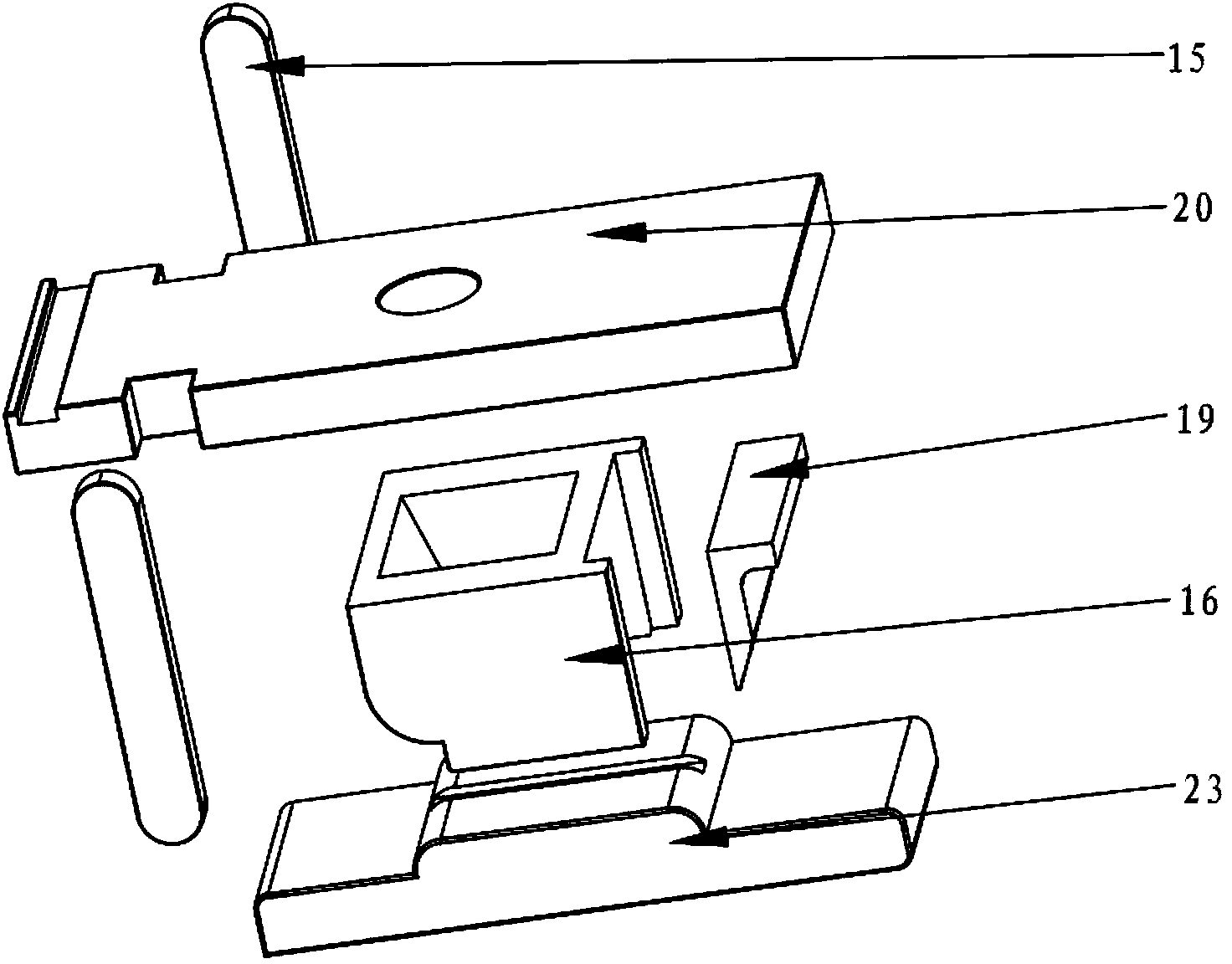

[0012] The main structure of the automatic gluing device for stacking zippers involved in this embodiment includes a feeding basket 1, a feeding transition wheel 2, a gluing mechanism 3, a drying box 4, a high temperature resistant transition wheel 5, a heating pipe 6, and a receiving guide wheel Group 7, one-way drive wheel 8, pressing wheel 9, motor 10, material receiving wheel 11, material receiving basket 12, heavy hammer wheel 13 and material receiving frame 14, and the front end of gluing mechanism 3 is fixedly arranged with upper and lower parts respectively by brackets. 2-5 rows of staggered and parallel feeding transition wheels 2 are used to transfer the ordinary coded zippers in the feeding basket 1 to the gluing mechanism 3. The drying box 4 is fixedly connected, and the inner bottom of the hollow box structure drying box 4 is provided with 1-3 rows of heating pipes 6 in a tiled tubular structure, and the upper and lower ends of the drying box 4 are respectively pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com