Indexable inserts for turning

A technology for indexing inserts and inserts, applied in the fields of machining inserts and indexable inserts for turning, can solve the problems of decreased surface quality of processed workpieces, limited ability to control chips, and affected surface quality of workpieces, so as to improve surface quality, The effect of increasing strength and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following are specific embodiments of the present invention, and further describe the technical solution of the present invention in conjunction with the accompanying drawings, but the present invention is not limited to these embodiments.

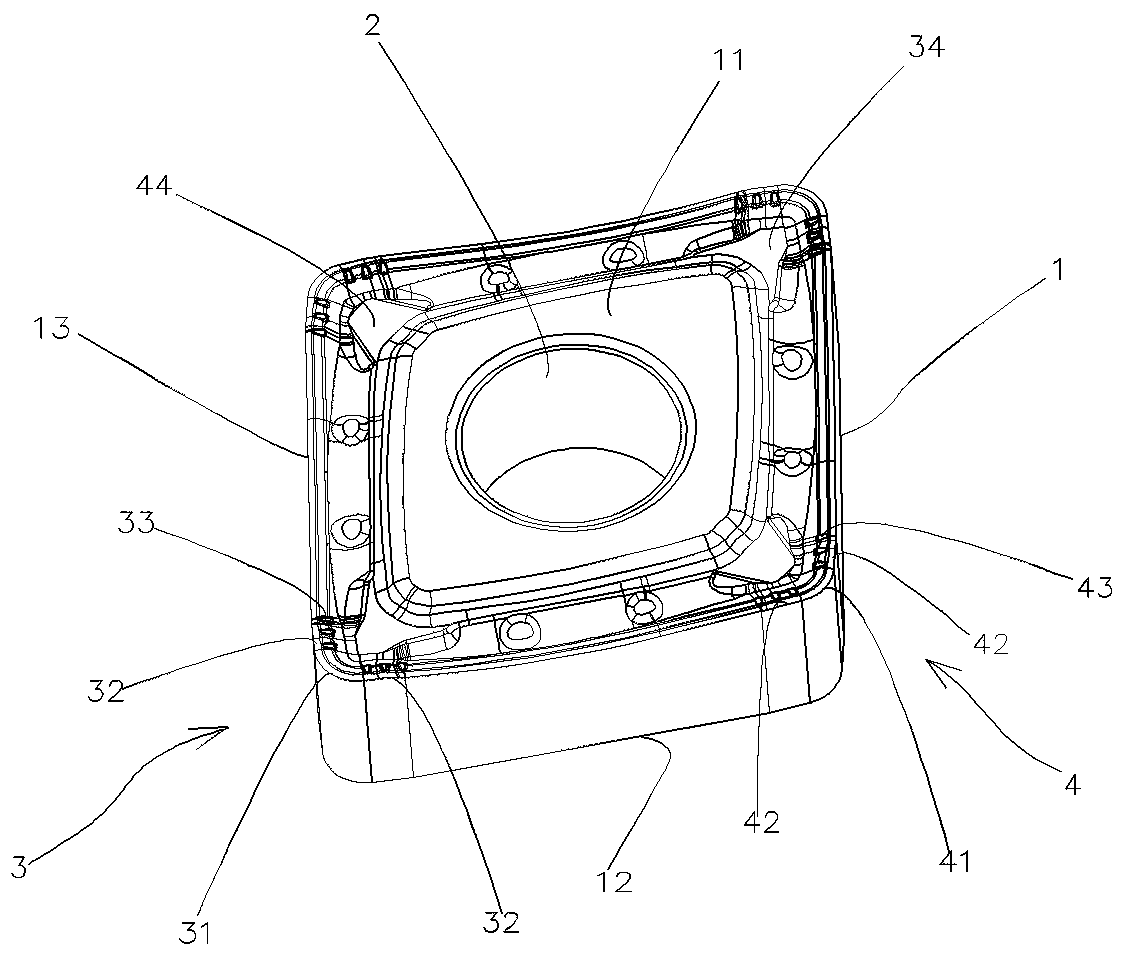

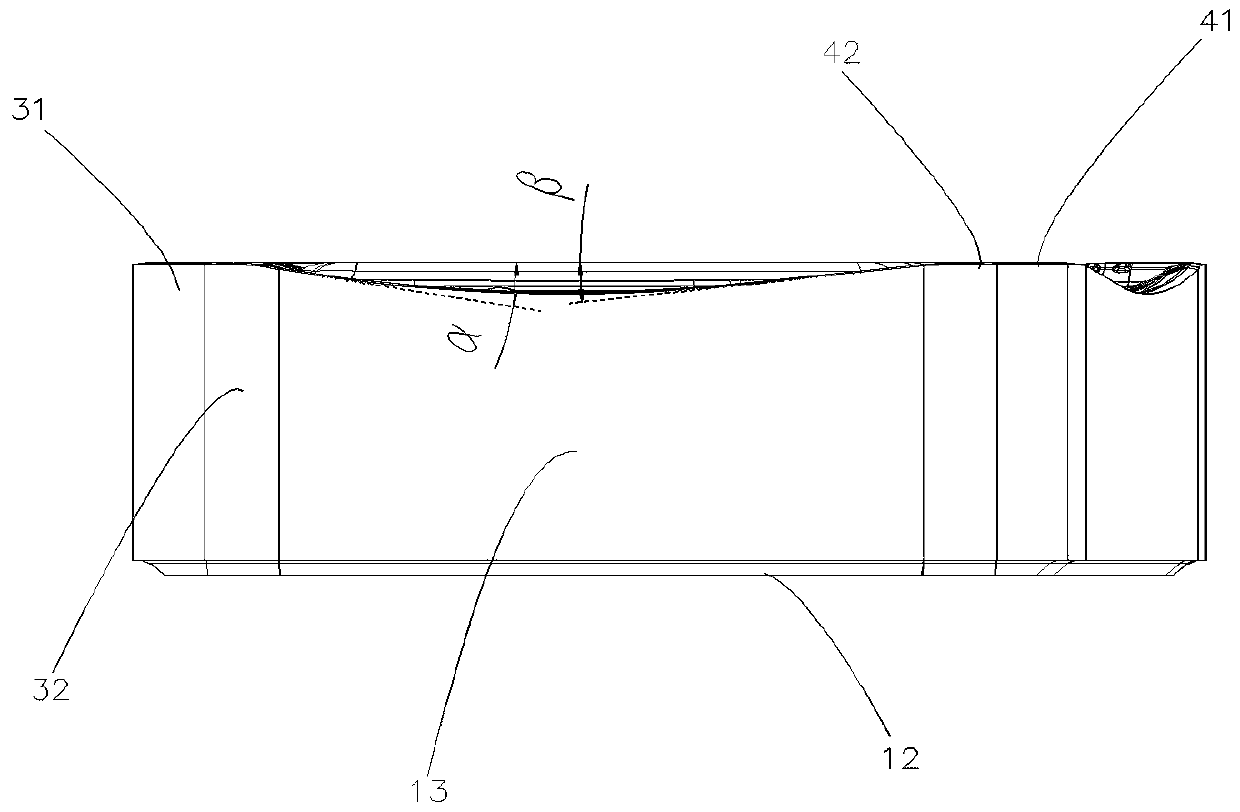

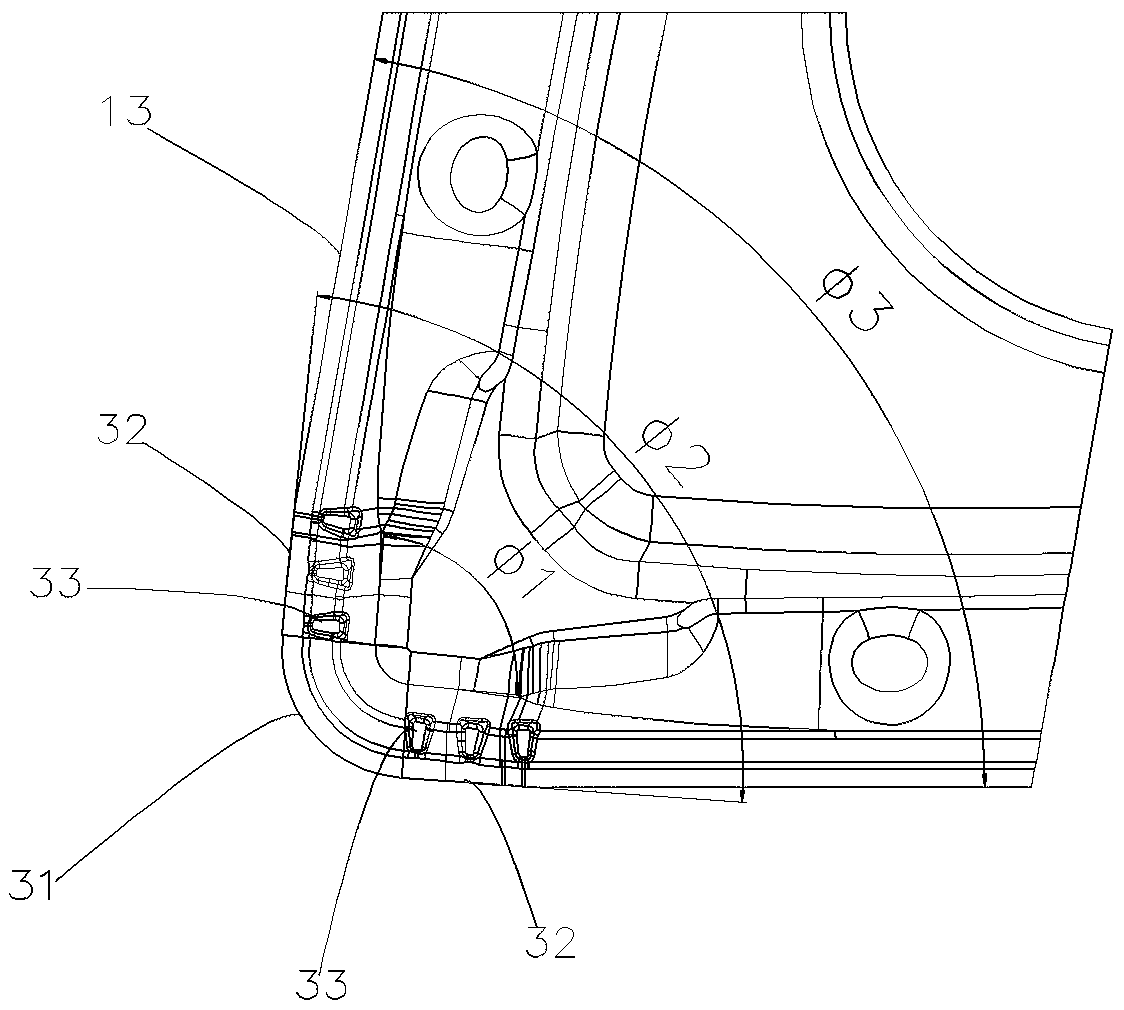

[0021] Such as figure 1 The shown indexable insert for turning includes a diamond-shaped insert body 1 , which is composed of an upper surface 11 , a lower surface 12 and four side surfaces 13 , and has a central hole 2 in the middle of the insert body 1 . Such as image 3 As shown, the main cutting edge portion 3 of the insert body 1 has a side angle of φ3, as Figure 4 As shown, the side angle of the secondary cutting edge portion 4 of the insert body 1 is θ3, and θ3>φ3 in this embodiment.

[0022] Such as figure 1 and image 3 As shown, the main cutting edge portion 3 is provided with a main cutting edge angle 31, and the two sides of the main cutting edge angle 31 are provided with a wiper edge 32, and the main cutting e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com