Tool for fixing and switching torque testing of valves

A torque test and switch technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of worker personal injury, increase labor, increase test speed, etc., and achieve the effect of improving measurement efficiency, reducing labor intensity, and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

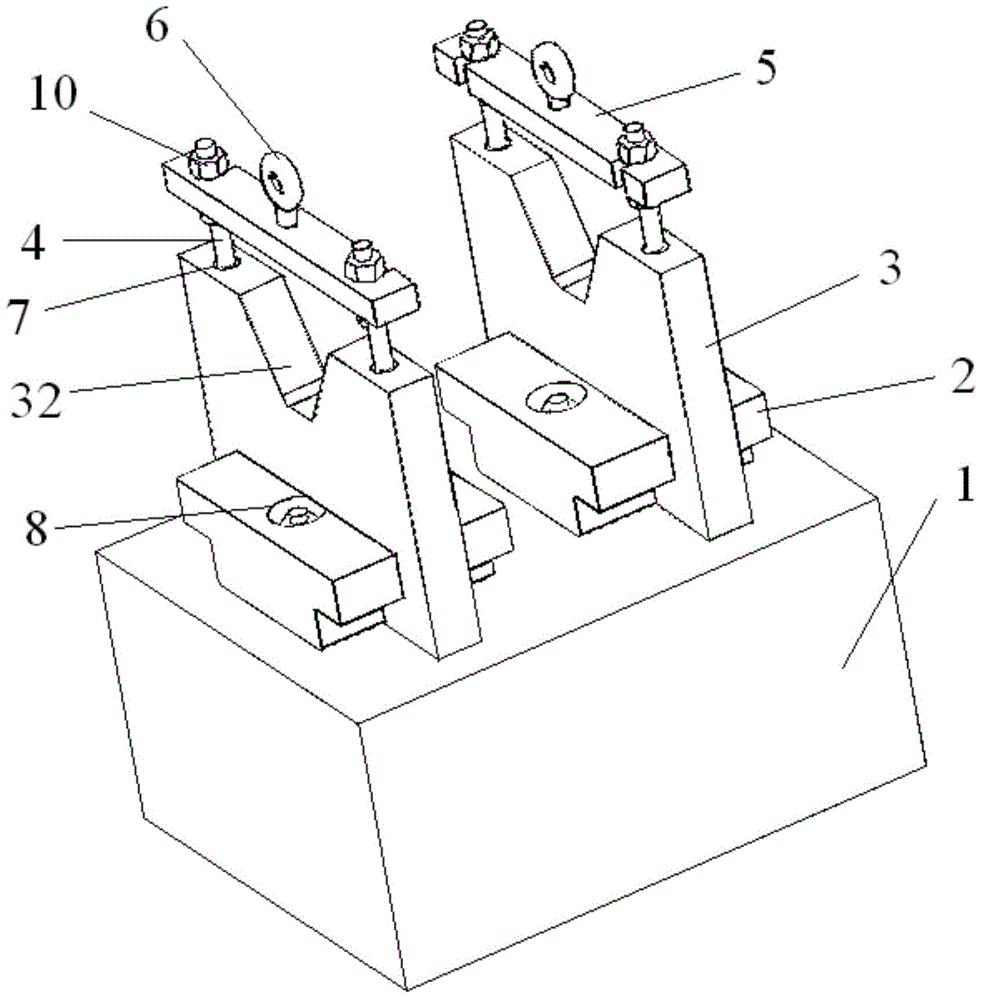

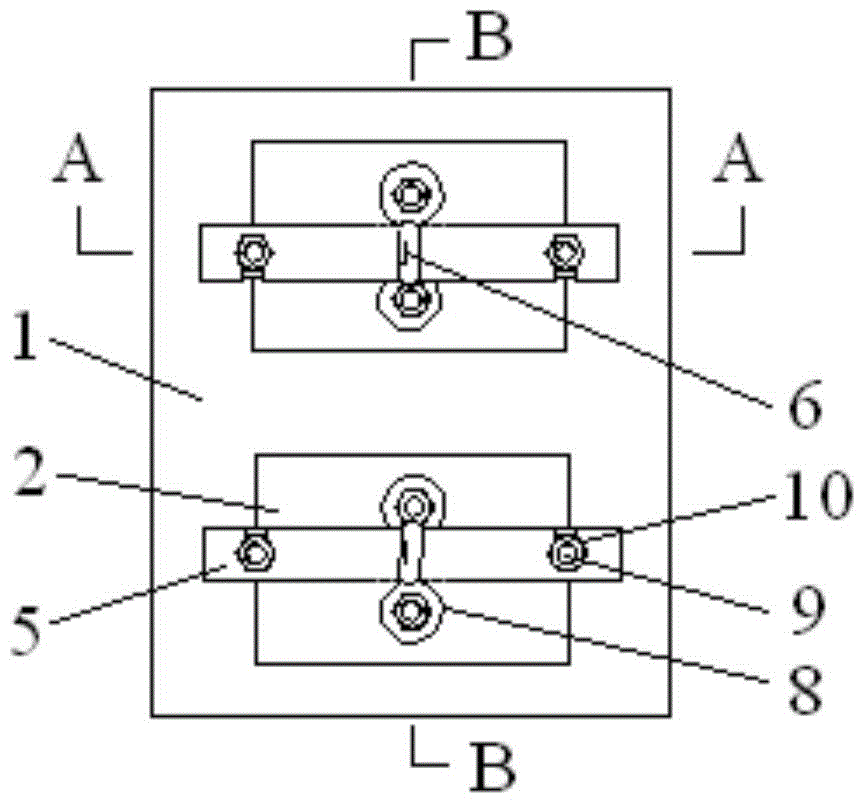

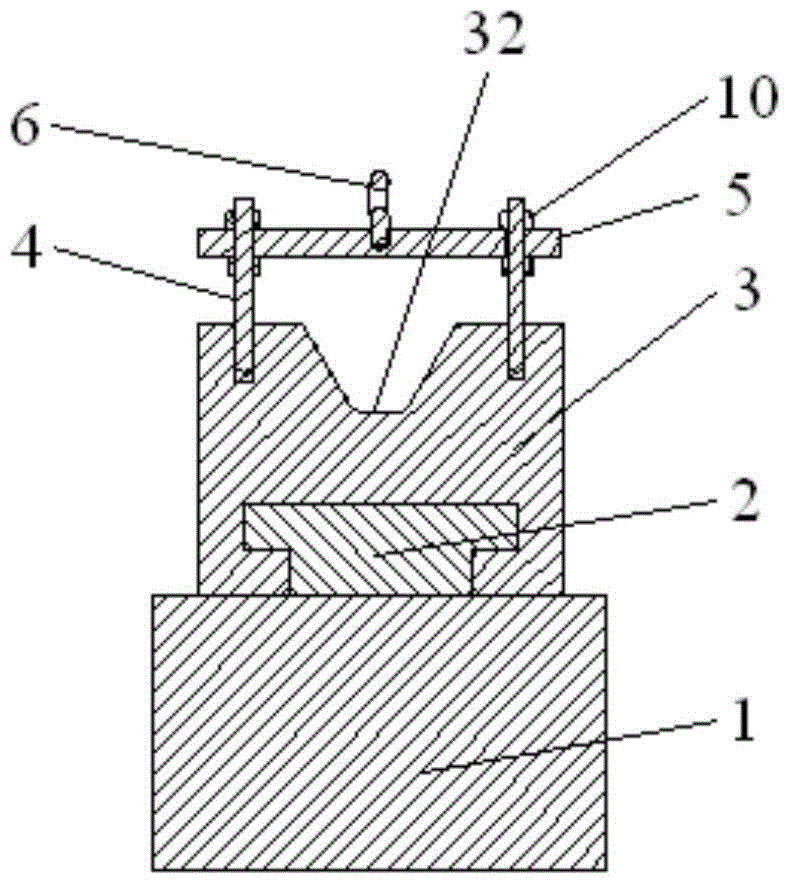

[0026] to combine Figure 1 to Figure 11 As shown, a tooling for valve fixing and switch torque testing, which includes: a base 1, a T-shaped block 2, a V-shaped block 3, a strut 4, a pressure plate 5 and a lifting ring 6; wherein, the upper surface of the base 1 A T-shaped block 2 is respectively fixed on the left and right sides; the two T-shaped blocks 2 are arranged side by side; the T-shaped block 2 is provided with a V-shaped block 3; the bottom surface of the V-shaped block 3 is provided with T-shaped groove 31, used to cooperate with T-shaped block 2; The top surface of the V-shaped block 3 is provided with a V-shaped groove 32; The top surface of the V-shaped block 3 is on both sides of the V-shaped groove 32 Each is provided with a pole 4; the pressure plate 5 is arranged between the two poles 4 and fixed on the pole 4; the middle position of the surface of the pressure plate 5 is provided with a suspension ring 6; the upper surface of the base 1 A threaded hole 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com