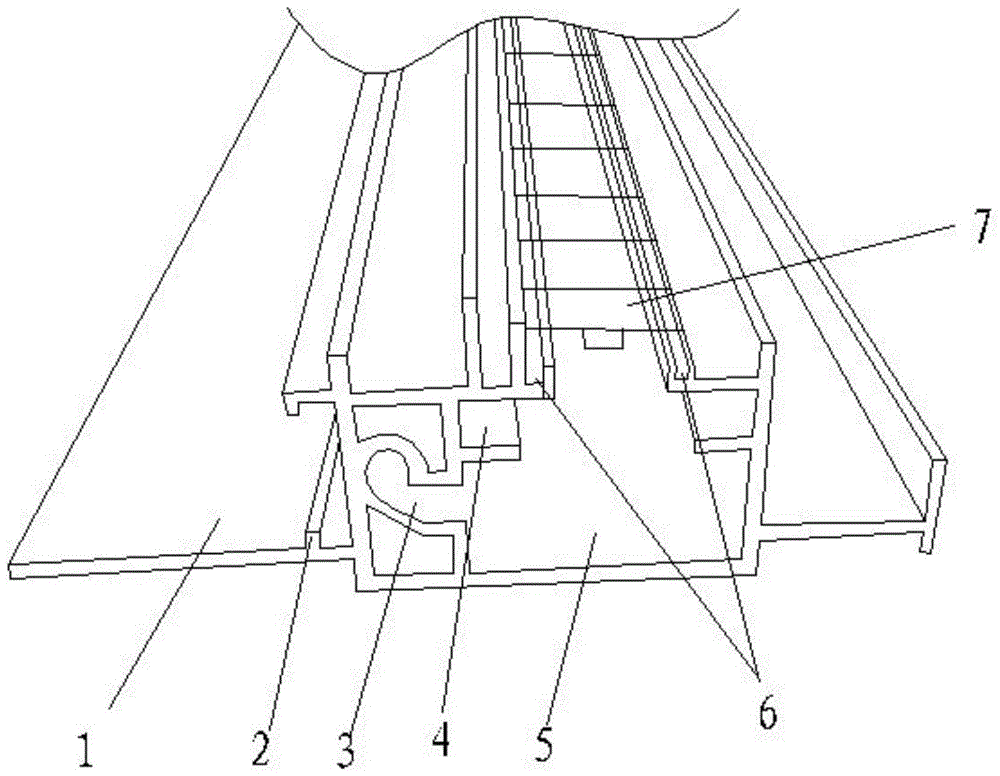

A dust-proof car sunroof slideway

A technology for car sunroofs and slideways, applied to vehicle parts, roofs, transportation and packaging, etc., can solve the problems of no dust-proof structure and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: The dust-proof device can adopt a non-woven fabric belt, the rear end of which is fixed to one end of the upper slide 4 by screws or bonding, and the front end is connected to the driving arm of the automobile sunroof transmission mechanism through a pull ring. Both sides of the belt are sewn with vertical edges, and the vertical edges are provided with multiple notches or gaps for easy folding.

Embodiment 2

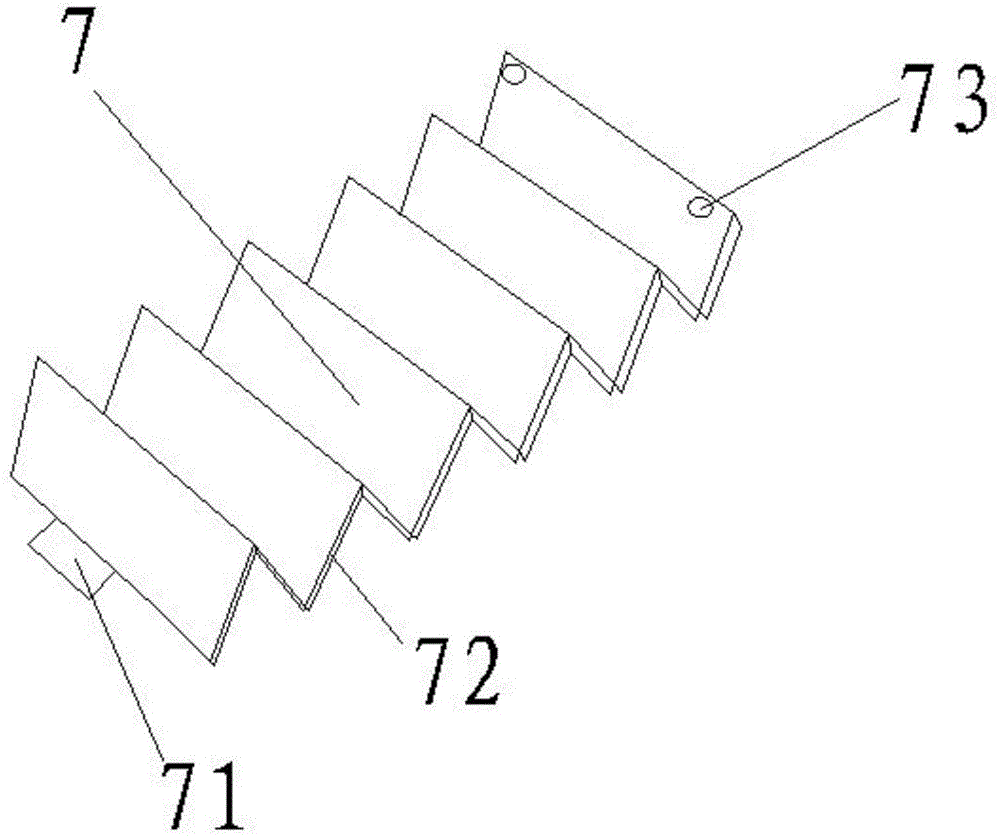

[0015] Example 2: see figure 2 , The anti-dust device adopts corrugated rubber belt 7. The wave rubber belt 7 includes a pull ring 71, a rubber edge lip 72 and a screw hole 73. The end of the wave rubber belt 7 is fitted with a screw through a metal edge with a screw hole 73, and is fixedly installed at one end of the upper surface of the upper slide 4. The ring 71 is installed on the driving arm of the automobile sunroof transmission mechanism, and the wave rubber belt is pulled by the driving arm to move. The rubber lip 72 is provided with a plurality of notches for easy folding.

[0016] When the sunroof is closed, the corrugated rubber belt 71 is squeezed to one end. When the sunroof is opened, the corrugated rubber belt 71 is pulled and unfolded by the driving arm. Both sides of the corrugated rubber belt 71 are vertically downwardly provided with rubber lip 72, which passes through the rubber lip. 72 can be matched with groove 6 to form a closed space, which can effectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com