A deformable reed device for experiment

A reed and experimental technology, applied in textiles, textiles, papermaking, looms, etc., can solve the problems of low experimental feasibility, large equipment transformation cost and technology, and achieve the effect of low cost and high experimental feasibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

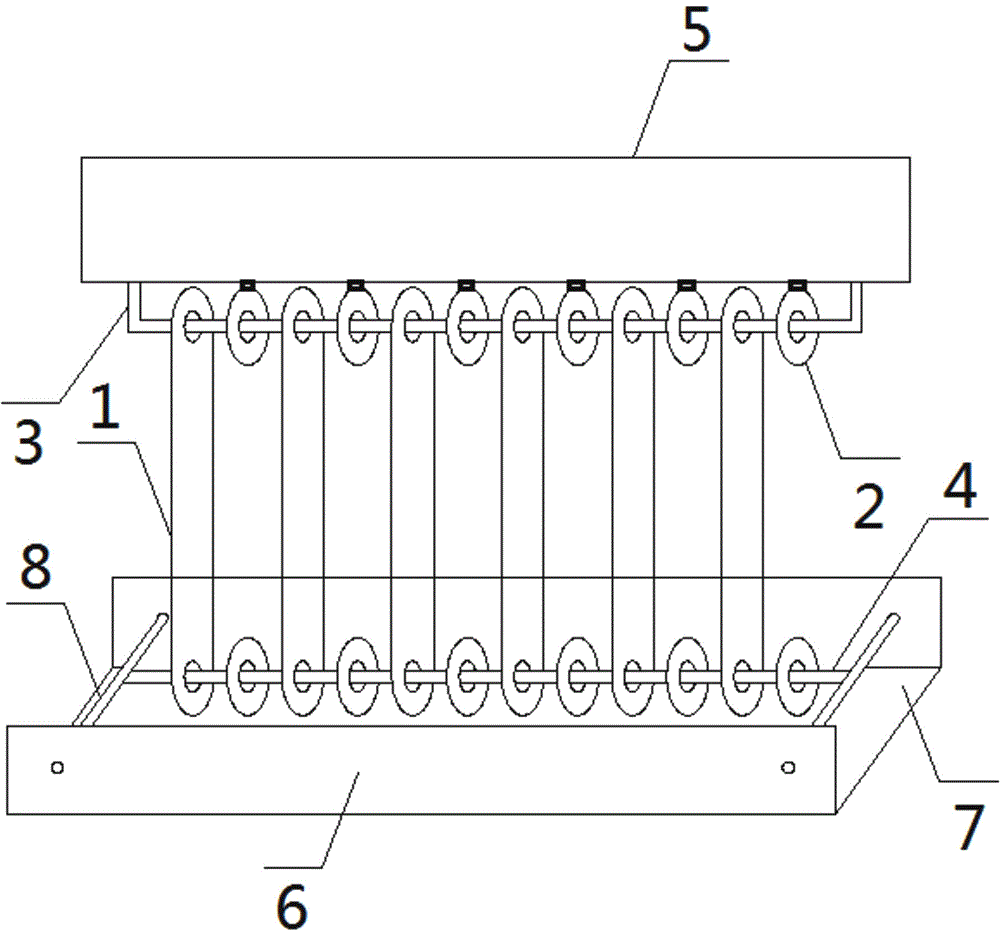

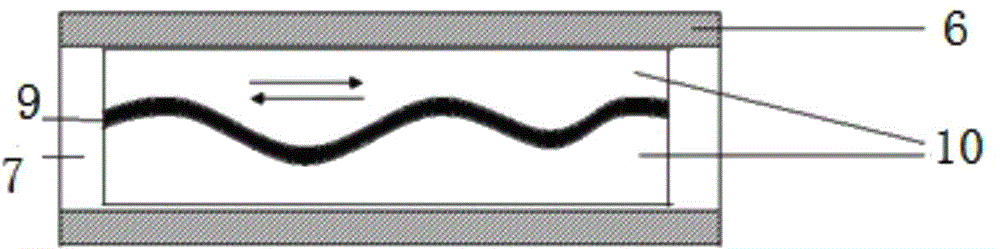

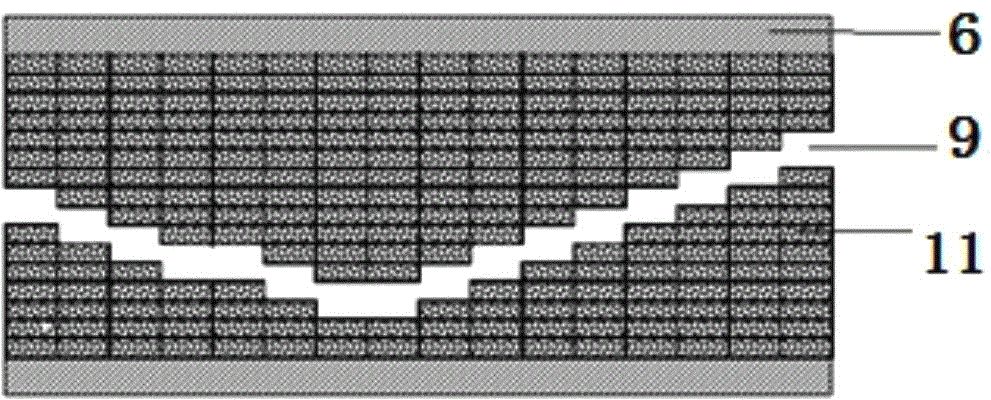

[0024] see figure 1 As shown, a deformable reed device for experiments includes a reed row 9, an upper reed beam 5, and a U-shaped groove type lower reed beam; the reed row 9 includes several reed pieces 1, and several circular spacers 2 , a straight cylindrical hard thin rod 3 and a first elastic thread 4; the two ends of the reed blade 1 are semicircular arc-shaped, and the diameter of the semicircular arc shape is equal to the width of the reed blade 1, so The first small hole is provided with the center of the semicircular arc on the reed sheet 1; the diameter of the circular spacer 2 is greater than the width of the reed sheet 1, and the center of the circular spacer 2 is provided with a The second small hole with the same diameter of the first small hole; the diameter of the straight cylindrical hard thin rod 3 and the first elastic thread 4 is smaller than the diameter of the first small hole; all the reed blades 1 The first small hole at one end and the second small h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com