Solder strip and flexible solar cell module

A technology of solar cells and welding ribbons, applied in the field of solar cells, can solve problems affecting the stability of solar cells, lack of ductility, and hidden cracks in solar cells, so as to improve photoelectric conversion efficiency, overcome non-extensibility, and elastic recovery performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

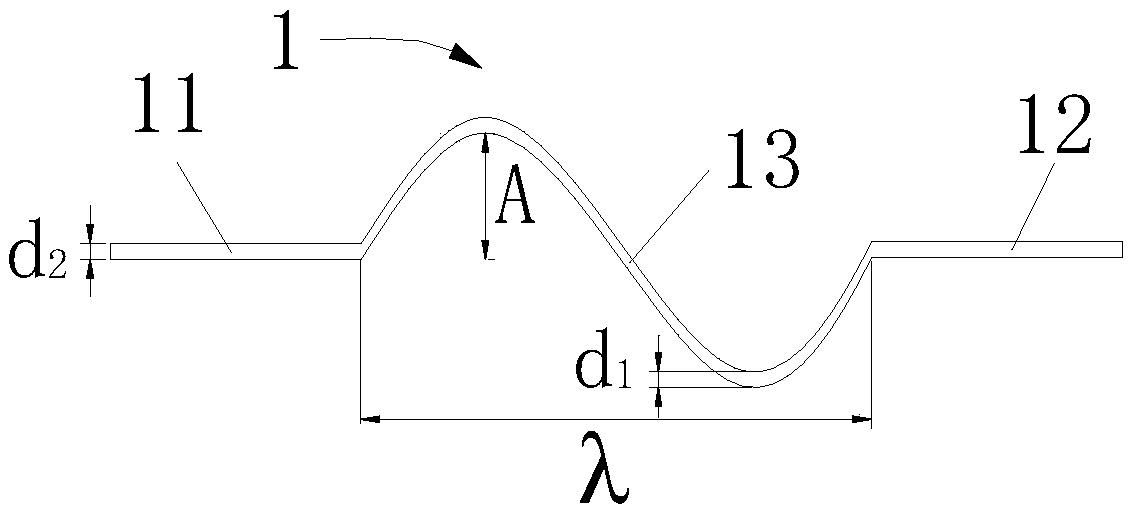

Embodiment 1

[0072] The welding ribbon 1 of this embodiment includes a first extension part 11 , a stretching part 13 and a second extension part 12 integrally formed. The stretching portion 13 is a curved segment structure, one end of the stretching portion 13 is connected to the first extension 11, the other end of the stretching portion 13 is connected to the second extension 12, and the first extension 11 and the second extension 12 collinear. Taking the connecting point of the stretching part 13 and the first extension part 11 as the origin of coordinates, the curve is a sinusoid with at least one complete period, and the period number of the sinusoid is K=1. The amplitude of the sinusoidal curve is A, the wavelength is λ, A:λ=1:5. The width of stretching portion 13 is d 1 , the widths of the first extension 11 and the second extension 12 are both d 2 , d 1 :D 2 =1:1.

Embodiment 2

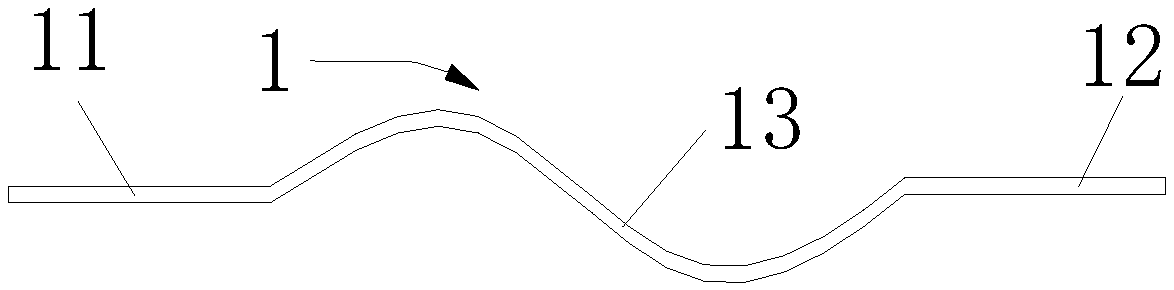

[0074] The only difference between this embodiment and Embodiment 1 is that A:λ=2:5.

Embodiment 3

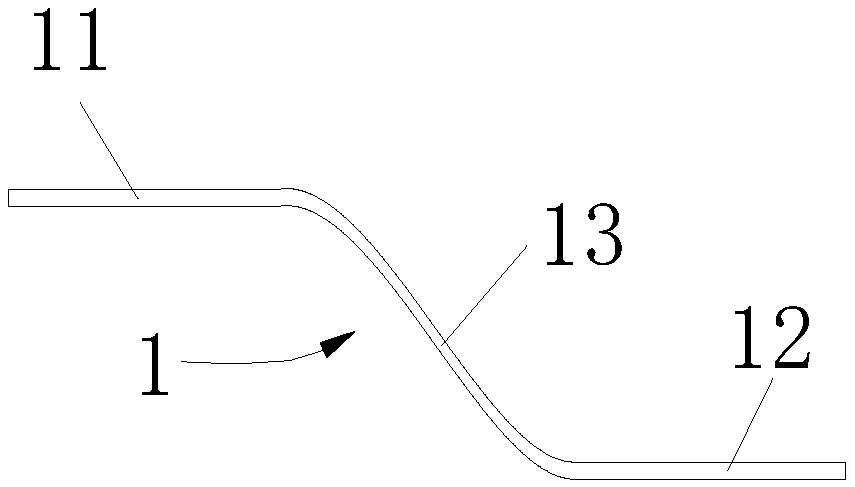

[0076] The only difference between this embodiment and Embodiment 1 is that A:λ=1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com