Freely deformable funnel and manufacturing method thereof

A funnel and rectangular technology, applied in the field of preparation of the funnel, can solve the problem that the funnel cannot adapt to various environments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

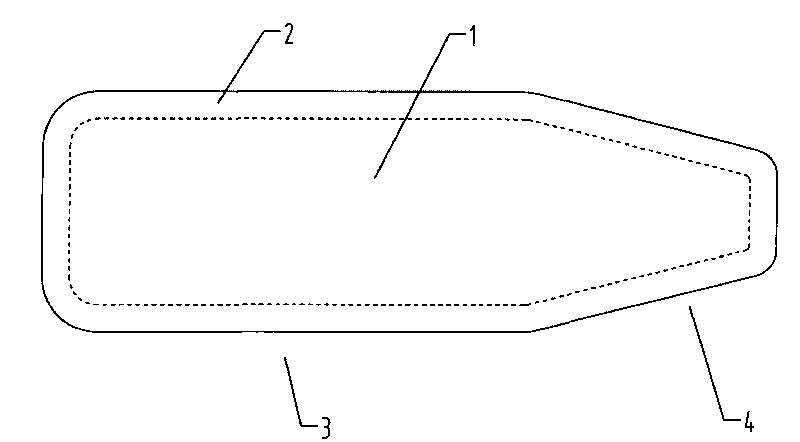

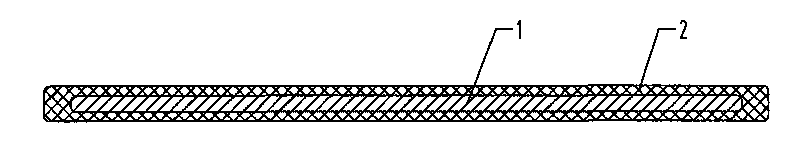

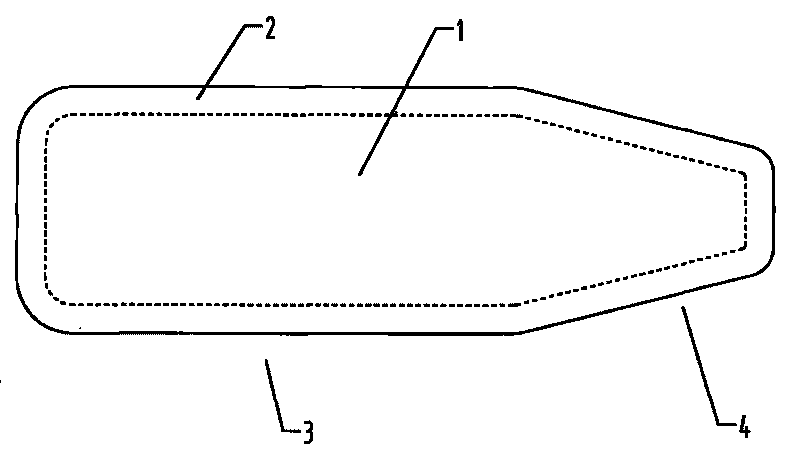

[0020] Example 1, such as figure 1 , figure 2 As shown, a funnel that can be deformed at will includes a funnel body. The funnel body is composed of a rectangular part 3 and a tapered part 4. The rectangular part 3 and the tapered part 4 are connected as one. The electrolytic lead plate 1 is used inside the funnel body. Made, coated with a vulcanized rubber layer 2 made of nitrile rubber film on the outside of the electrolytic lead plate.

[0021] The preparation method of above-mentioned funnel is: at first, get electrolytic lead plate 1 and cut it into such as figure 1 The shape of the structure shown in , and round it around, and wipe the surface clean without dirt or oil; then, mix 80 parts of nitrile rubber, 40 parts of kaolin, 2 parts of zinc oxide, stearin 1 part of acid, 1 part of sulfur and 1 part of accelerator NS are mixed on an open mill according to the ratio of parts by weight to make a nitrile rubber film of required size.

[0022] The mixing process is:

...

Embodiment 2

[0026] Example 2, such as figure 1 , figure 2 As shown, a funnel that can be deformed at will includes a funnel body. The funnel body is composed of a rectangular part 3 and a tapered part 4. The rectangular part 3 and the tapered part 4 are connected as one. The electrolytic lead plate 1 is used inside the funnel body. Made, coated with a vulcanized rubber layer 2 made of nitrile rubber film on the outside of the electrolytic lead plate.

[0027] The preparation method of above-mentioned funnel is: at first, get electrolytic lead plate 1 and cut it into such as figure 1 The shape of the structure shown in , and round it around, and wipe the surface clean without dirt or oil; then, mix 120 parts of nitrile rubber, 60 parts of kaolin, 4 parts of zinc oxide, stearin 3 parts of acid, 3 parts of sulfur and 3 parts of promotor NS are mixed on the open mill according to the proportioning by weight, and the nitrile rubber film of required size is made,

[0028] The mixing process...

Embodiment 3

[0031] Example 3, such as figure 1 , figure 2 As shown, a funnel that can be deformed at will includes a funnel body. The funnel body is composed of a rectangular part 3 and a tapered part 4. The rectangular part 3 and the tapered part 4 are connected as one. The electrolytic lead plate 1 is used inside the funnel body. Made, coated with a vulcanized rubber layer 2 made of nitrile rubber film on the outside of the electrolytic lead plate.

[0032] The preparation method of above-mentioned funnel is: at first, get electrolytic lead plate 1 and cut it into such as figure 1 The shape of the structure shown in , and round it around, and wipe the surface clean without dirt or oil; then, mix 100 parts of nitrile rubber, 50 parts of kaolin, 3 parts of zinc oxide, stearin 2 parts of acid, 2 parts of sulfur and 2 parts of promotor NS are mixed on the open mill according to the proportioning by weight, and the nitrile rubber film of required size is made,

[0033] The mixing process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com