Hydraulic operating mechanism for high pressure switch and hydraulic working cylinder thereof

A technology of hydraulic operation and high-voltage switch, which is applied to high-voltage/high-current switches, power devices inside switches, electric switches, etc., and can solve problems such as increased cost and floor space, large hydraulic mechanism size, and large shock vibration. To achieve the effect of improving stability, rapid increase in motion speed, and increased acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

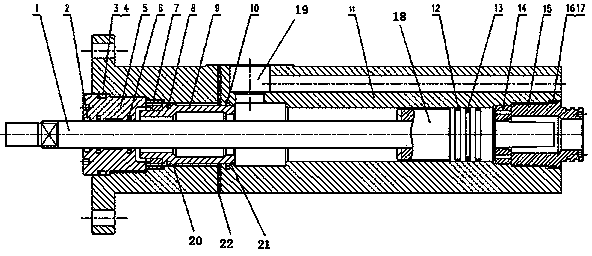

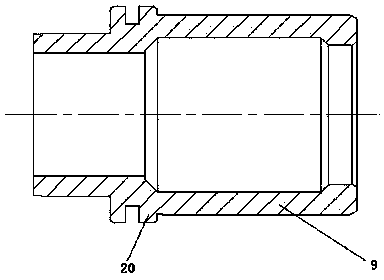

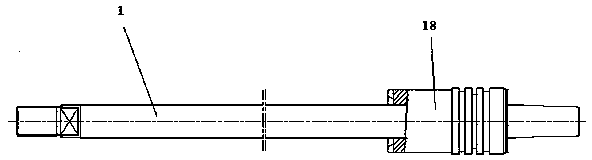

[0023] Embodiments of the hydraulic cylinder of the present invention are Figure 1-3As shown: the hydraulic working cylinder includes a cylinder body 11 with an inner chamber, a main piston 18 that is sealed and slidably fitted in the inner chamber of the cylinder body 11, and the inner chamber of the cylinder body 11 is separated by the main piston 18 to be on the left side of the main piston 18 The rod chamber on the right side of the main piston 18 and the rodless chamber on the right side of the main piston 18, the main piston 18 is fixed with the piston rod 1 extending in the left and right direction through the rod chamber, and the rod chamber of the cylinder body 11 along the An auxiliary piston 9 independent of the piston rod 1 is slidably mounted in the left and right directions.

[0024] The left end of the cylinder body 11 rod cavity is provided with a left nut 5 with an inner hole that is rotatably matched with the inner wall of the rod cavity. The left end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com