Water Inlet Expanding Pipe Structure and Pumping Station Rectification Method

A technology of gradually expanding pipes and entering water, applied in pumping stations, siphon pipes, pipe components, etc., can solve the problems of easy formation of vortex funnels, unstable water flow, and achieve the effect of simple engineering measures and improved diffusion state.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

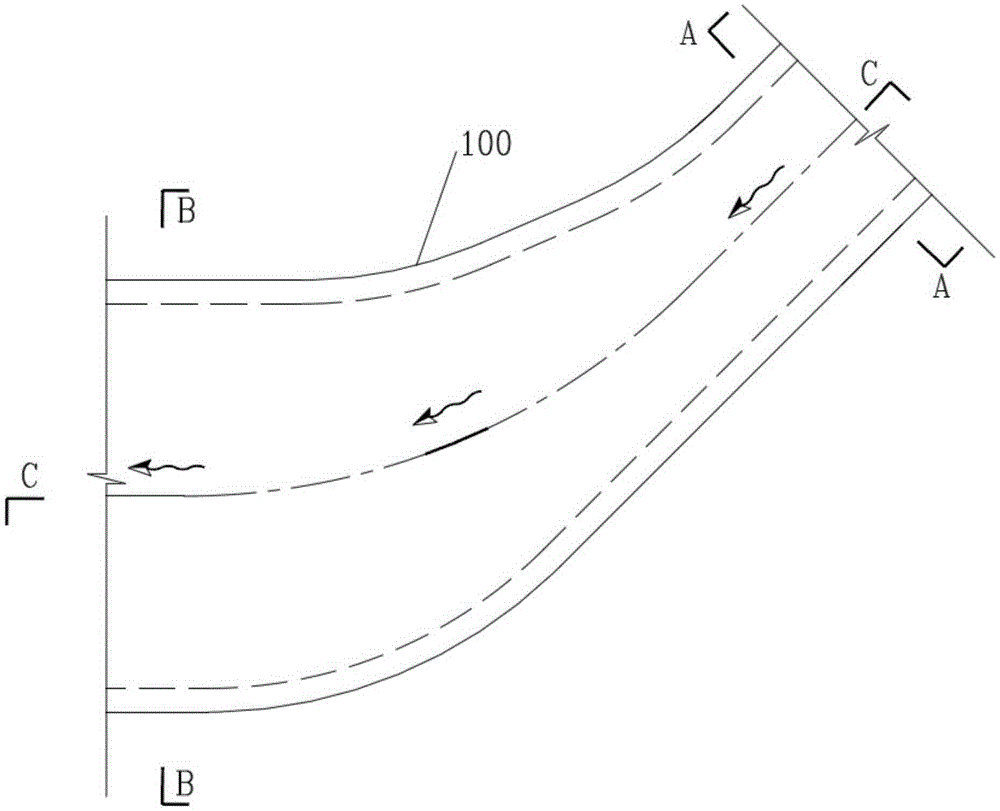

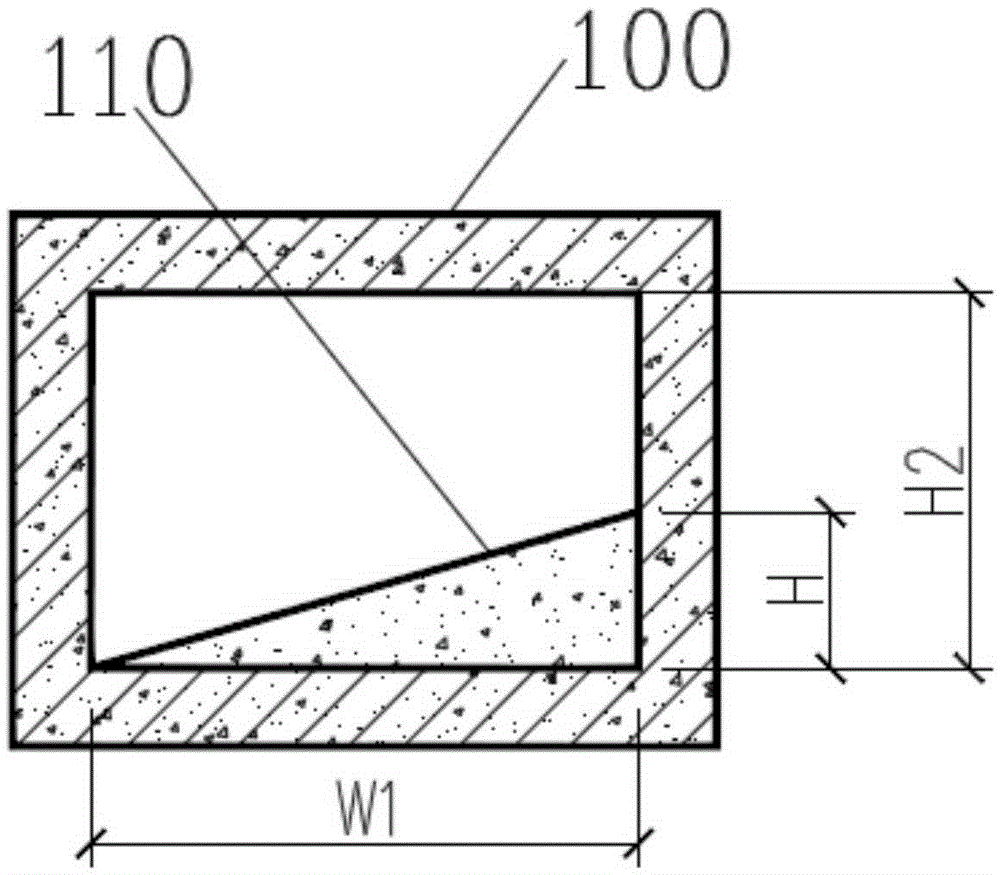

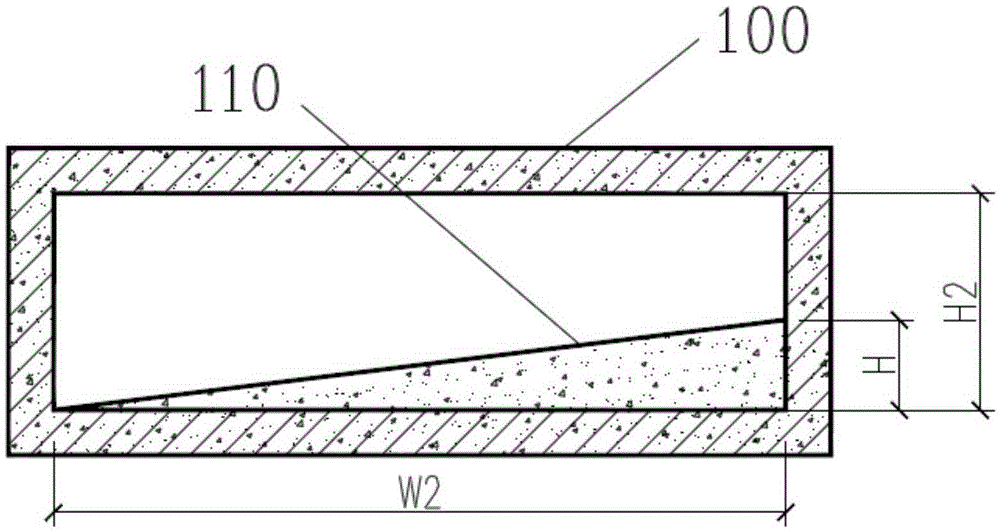

[0020] Such as Figure 1 to Figure 4 As shown, a water inlet expander structure in this embodiment includes a water inlet expander 100, the water inlet expander 100 is a curved pipe, and the inner bottom surface of the water inlet expander 100 is set as an inclined surface 110 The inclined surface 110 is inclined from the outside to the inside. When the water flow passes through the water inlet expander 100, the centrifugal force formed by the turning will be offset by the centripetal force provided by the flow on the inclined surface 110, so that the water flow is evenly distributed on the inclined surface 110.

[0021] Exemplarily, the cross-section of the water inlet diverter 100 in this embodiment is rectangular, and the outer side of the inner bottom surface of the water inlet diverter 100 is higher than the inner side by H=1000mm, such as figure 2 The water inlet width W1 of the water inlet diverter 100 shown is 3500mm, and the height H1 is 2400mm; image 3 The water o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com