Label defect detecting method

A defect detection and labeling technology, which is applied in the field of image processing, can solve problems such as inability to check characters, achieve the effect of reducing the amount of calculation and improving the comparison efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

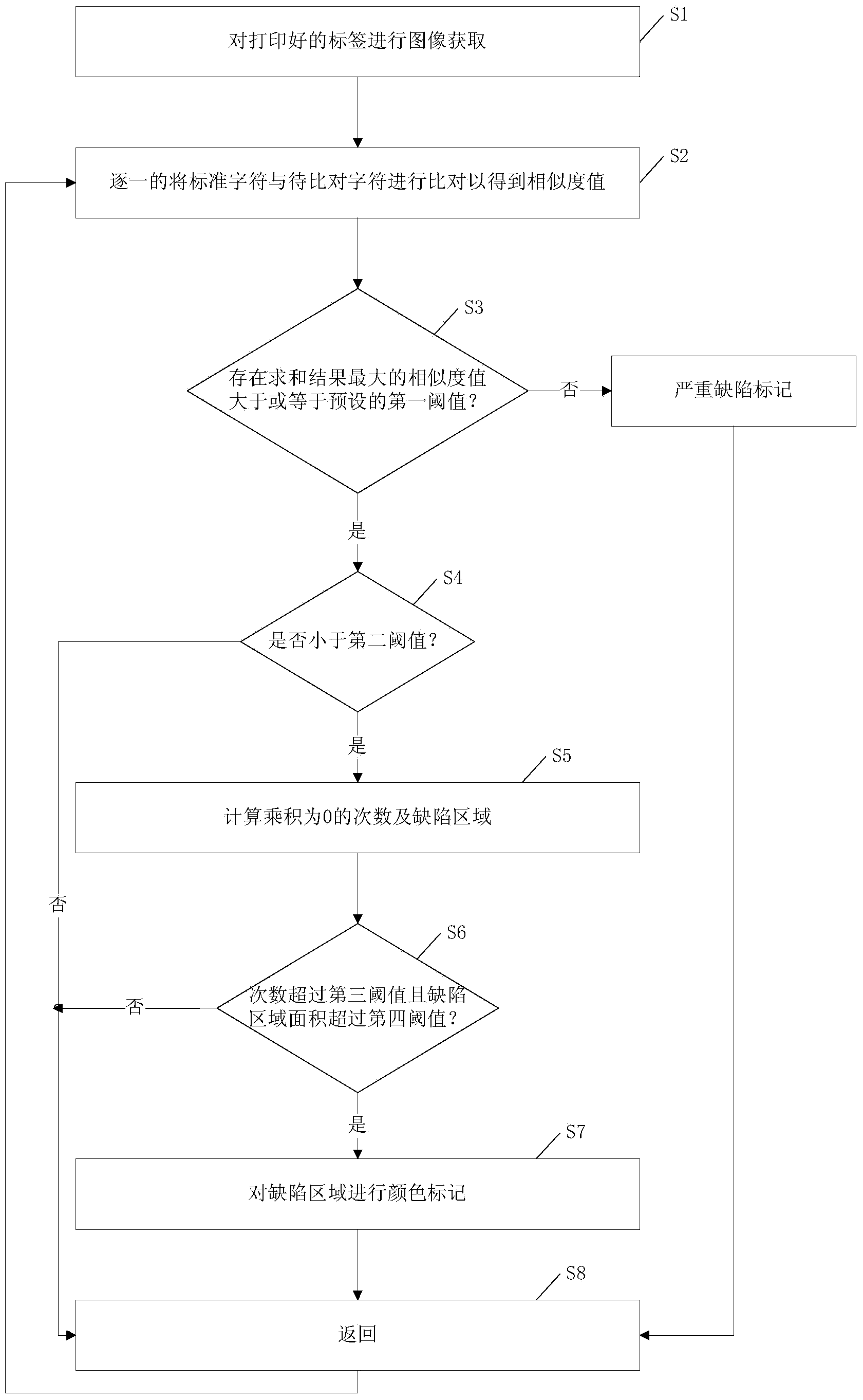

Method used

Image

Examples

Embodiment Construction

[0033] In the following, the present invention will be further described in conjunction with the drawings and specific embodiments.

[0034] This embodiment discloses a label defect detection method. Before executing this method, standard characters can be acquired, and the acquisition process is as follows:

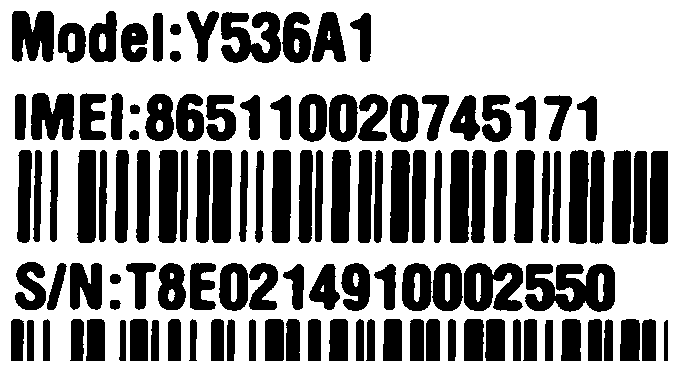

[0035] In step A, a camera with 5 million pixels can be used to acquire an image of an area containing a character to obtain the character area. The characters may be any one of English letters, Chinese characters, numbers and icon symbols.

[0036] Step B, performing binarization processing on the character area to obtain a binarized image of the entire character area.

[0037] Step C, performing image processing on the binarized character area by using an open operation to remove edge burrs.

[0038] Step D. Delete graphics that do not match the preset font size (ie, the preset length and height values) to obtain characters. In this way, the interference of some gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com