Improved Vacuum Dryer for Industrial Leather

A vacuum dryer and drying machine technology, applied in the field of tanning, can solve time-consuming problems, achieve the effects of reducing power consumption, reducing pressure loss, increasing suction capacity and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

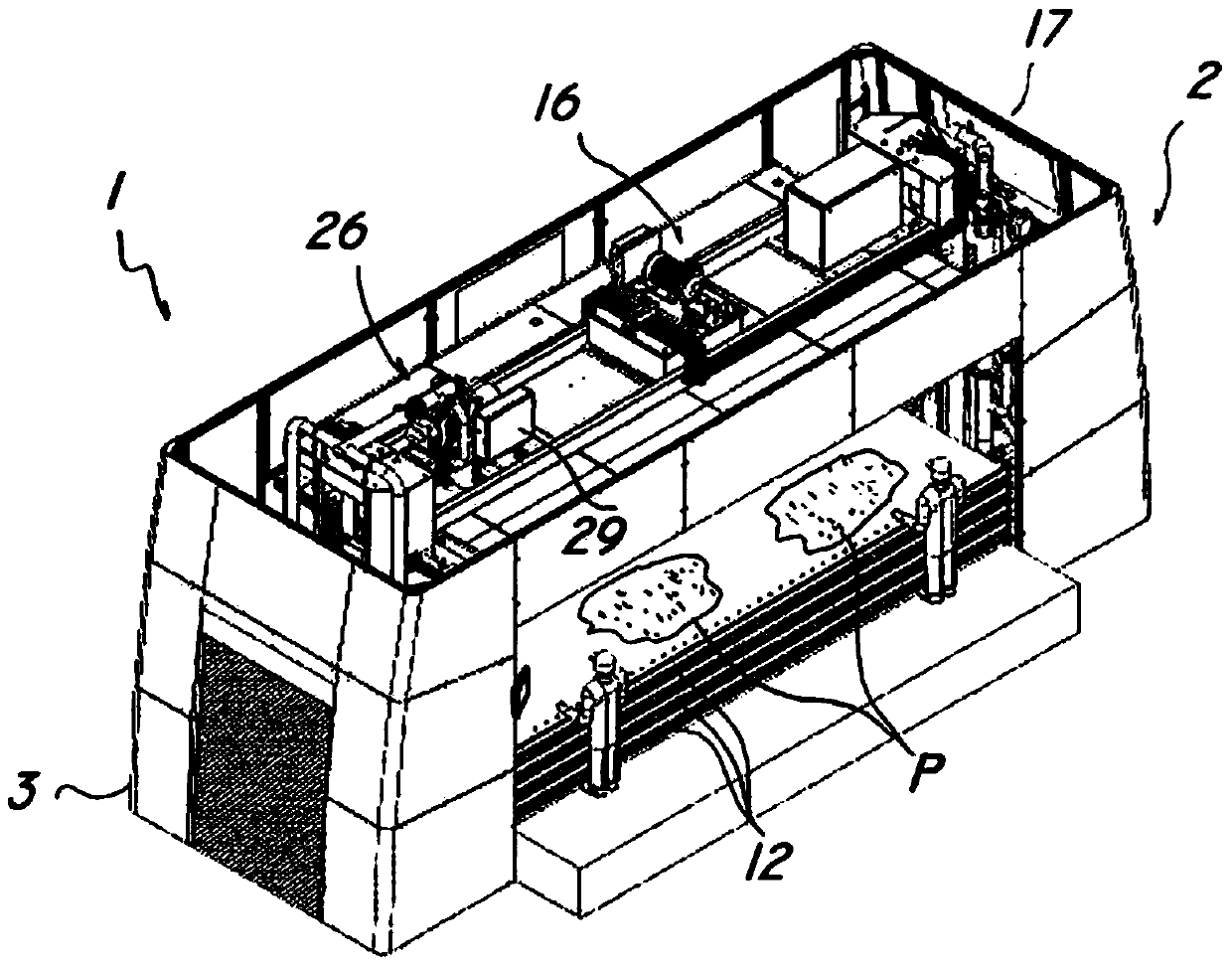

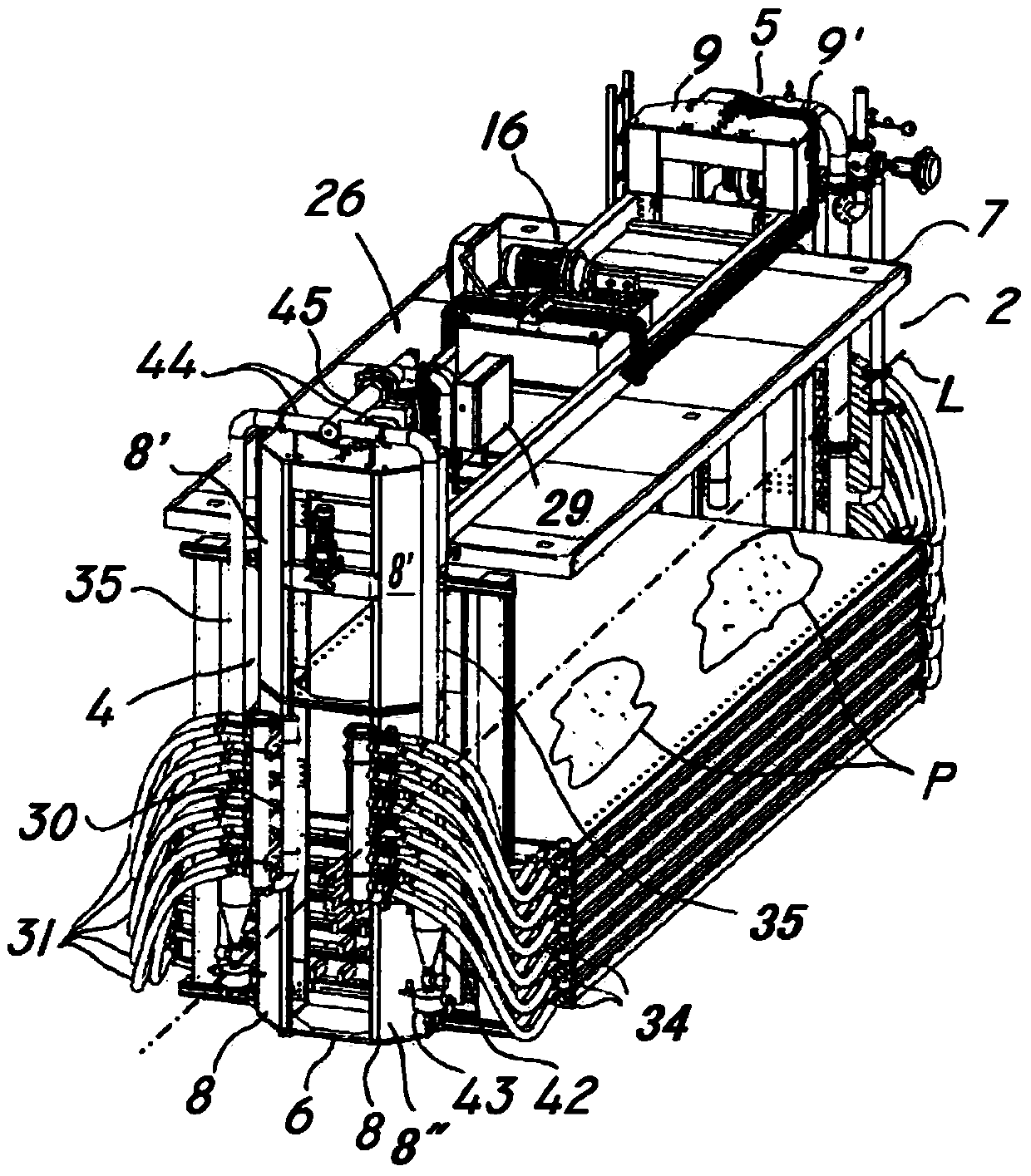

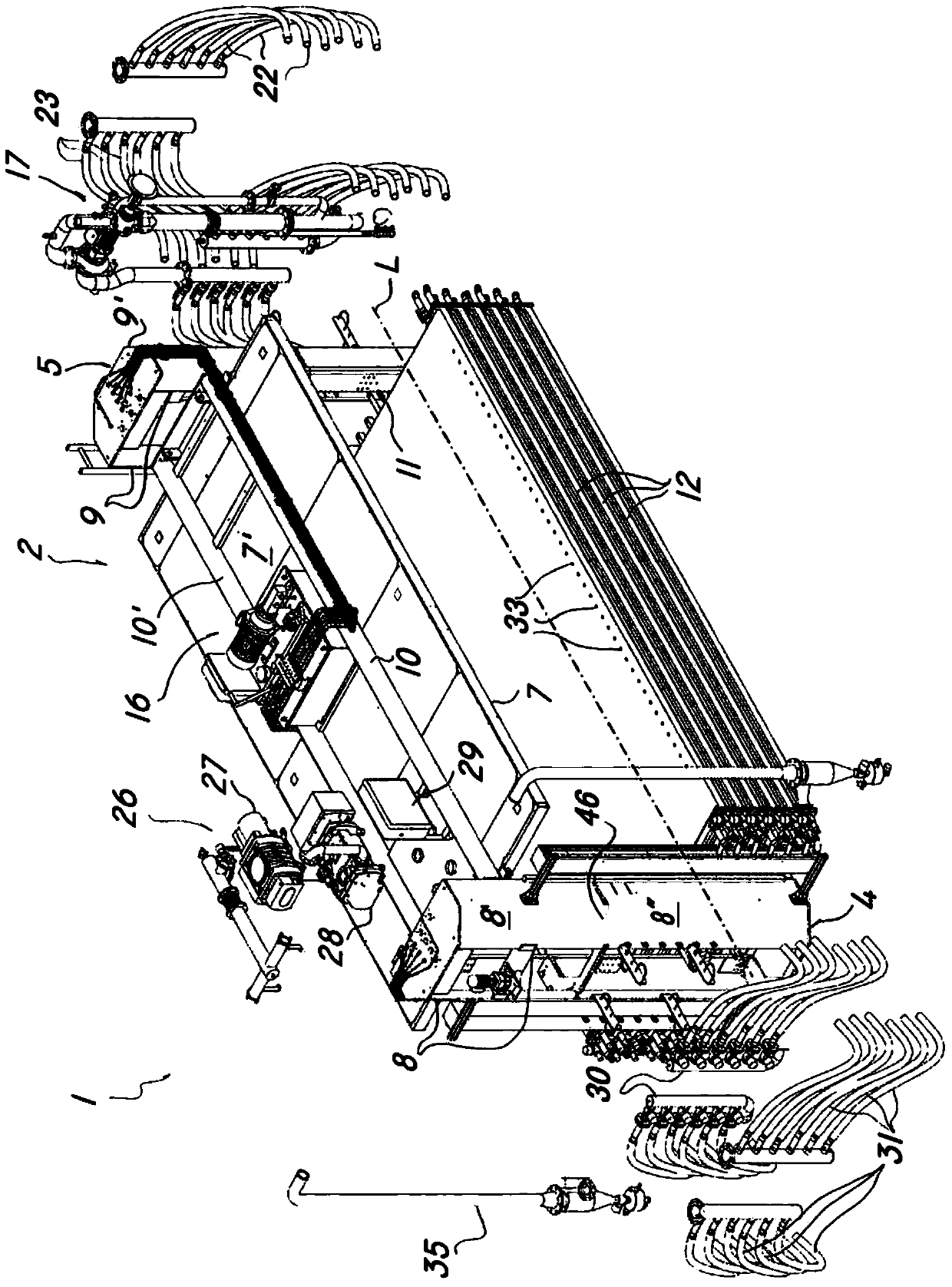

[0039] With reference to the above figures, the drying machine of the invention, indicated generally by reference number 1 , is especially designed to dry flat products, such as industrial leather P which has been subjected to a tanning process and which retains a high moisture content.

[0040] The dryer 1 comprises a body consisting of a support structure 2 defining a longitudinal axis L and completely covered by a removable guard 3 .

[0041] In the embodiment in the figures, the guard 3 has at its longitudinal ends two sliding doors 3' which can be lifted for easy access to the interior of the machine without dismantling the whole guard.

[0042] The support structure 2 basically consists of a pair of longitudinally offset end columns 4 , 5 , a base 6 between the columns 4 , 5 , and a flat cover 7 .

[0043] Preferably, as Figure 4 As better shown in , the uprights 4, 5, the base 6 and the cover 7 are rigidly connected together so that a rigid and integral support s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com